Program your firings manually, calibrate the final temperature using cones

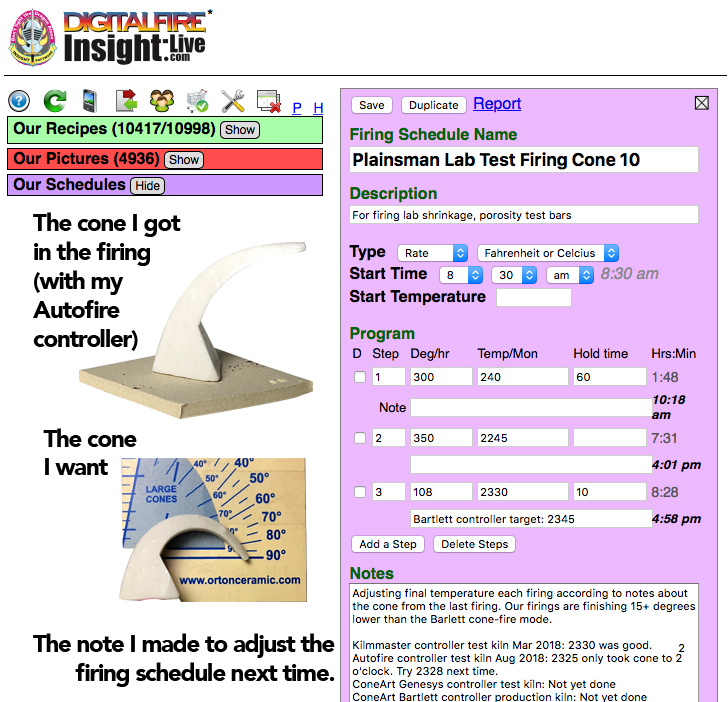

Here is an example of our lab firing schedule for cone 10 oxidation (which the cone-fire mode does not do correctly). To actually go to cone 10 we need to manually create a program that fires higher than the built in cone-fire one. Determining how high to go is a matter repeated firings verified using a insight-live.com/picture/2223">self-supporting cone (regular cones are not accurate). In our lab we keep notes in the schedule record in our account at insight-live.com. And we have a chart on the wall showing the latest temperature for each of the cones we fire to. What about cone 6? Controllers fire it to 2235, we put down a cone at 2200!

Pages that reference this post in the Digitalfire Reference Library:

Cones bending theoretically, cones bending actually, Are you using your expensive kiln like a pop-up toaster?, At what point is a self-supporting cone bent to the correct degree?, Be thankful for the hobby kiln controllers we have in North America, Kiln Controller, Firing Schedule, Pyrometric Cone, Plainsman Cone 6 Electric Standard, Cone 6 Drop-and-Soak Firing Schedule, Cone 03 Fast Fire, Plainsman Low Temperature Drop-and-hold, Plainsman Electric Bisque Firing Schedule, Low Temperature Drop-and-Hold, Plainsman Cone 6 Drop-and-hold, Slow Cool

This post is one of thousands found in the Digitalfire Reference Database. Most are part of a timeline maintained by Tony Hansen. You can search that timeline on the home page of digitalfire.com.