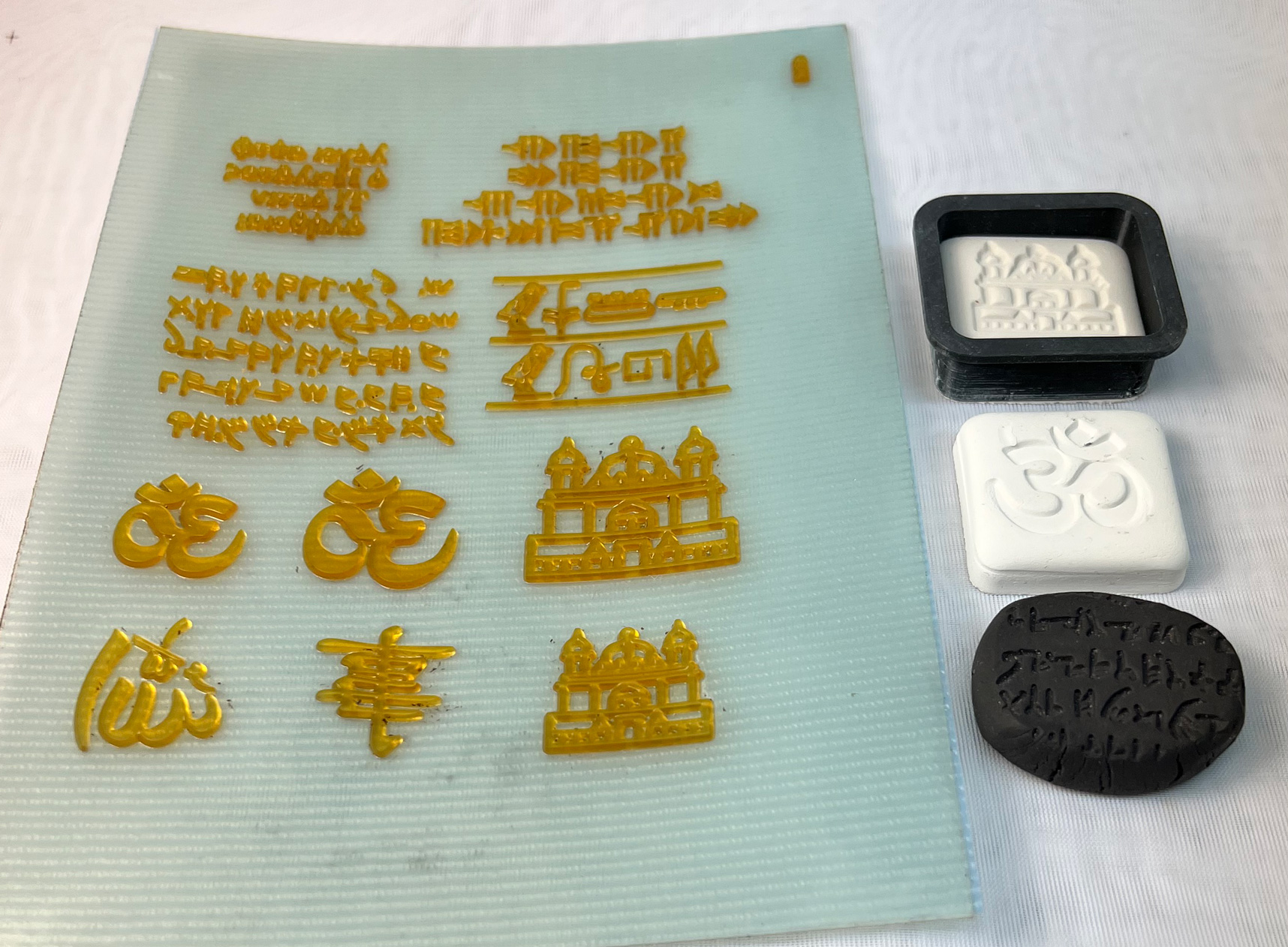

Letterpress plates from BoxcarPress.com. Great for DIY stamping.

We find the 0.047 relief depth shown here is best (K152), especially when pigment is used to highlight the recesses. It can be valuable to put a border around the outside so edges do not smear outward when pressing. These flexible plates do not need to be stuck to a piece of wood, just lay them face down on the clay and use a wooden block to press them down. When the clay is stiff enough no parting agent is needed. The cost: In 2024 the minimum charge is $37.5 for 50 square inches. They have an highly streamlined checkout that accepts PDF and AI vector files. The cart might generate all four CMYK plates, remove the CMY ones and keep the K (black). The most common mistake is having too much detail or too small printing. Or, forgetting to make them reverse-reading. It is best to make your images using vector graphic software like Illustrator, Inkscape, CorelDraw, etc.

Pages that reference this post in the Digitalfire Reference Library:

Example of a logo done using a polymer plate, Cone 6 stoneware coffee mug with a letterpress-made stamp, Letterpress plates: Design for the draft, Making ceramic "stones that cry out", Boxcar Press website, Amaco ceramic printing inks, 3D Printing a Clay Cookie Cutter-Stamper

This post is one of thousands found in the Digitalfire Reference Database. Most are part of a timeline maintained by Tony Hansen. You can search that timeline on the home page of digitalfire.com.