A high feldspar glaze is settling, running and crazing. What to do?

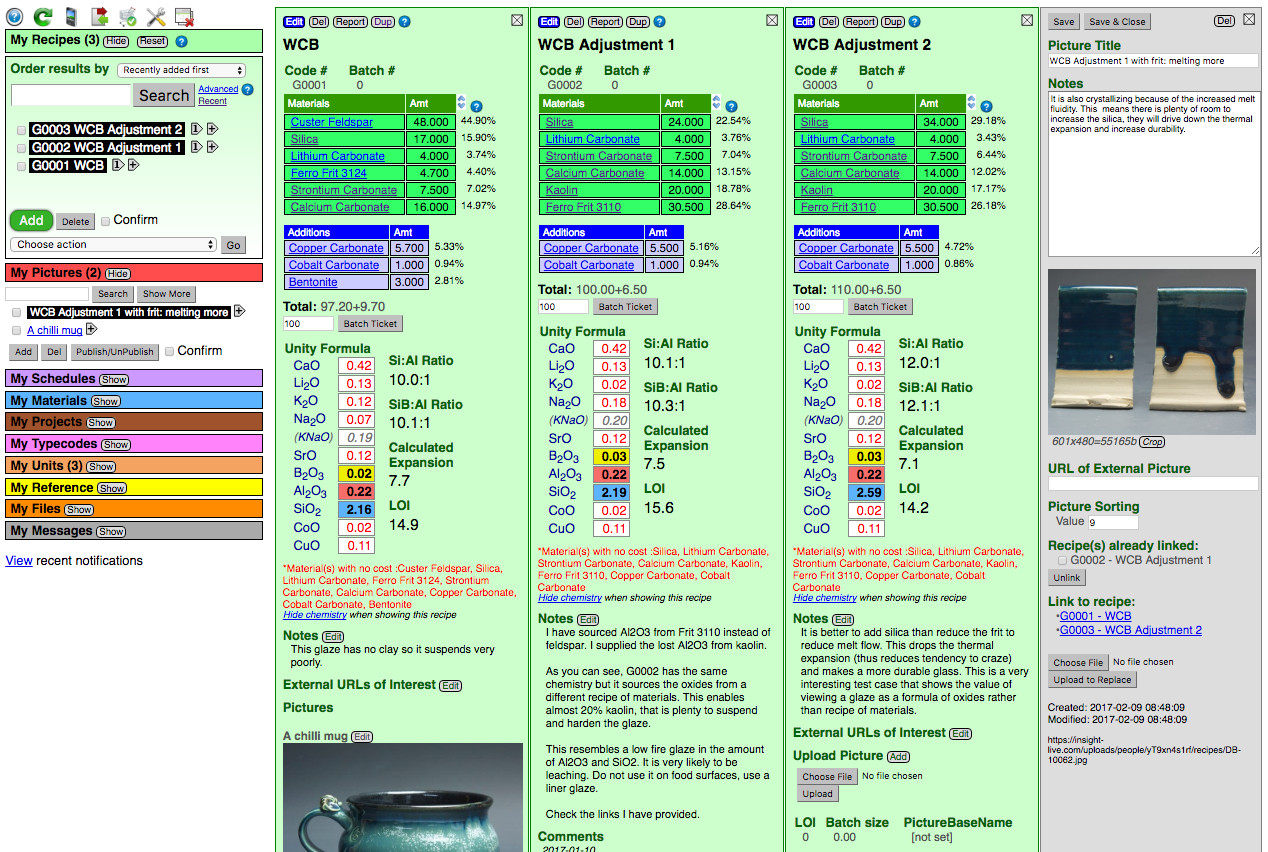

The original cone 6 recipe, WCB, fires to a beautiful brilliant deep blue green (shown in column 2 of this Insight-live screen-shot). But it is crazing and settling badly in the bucket. The crazing is because of high KNaO (potassium and sodium from the high feldspar). The settling is because there is almost no clay in the recipe. Adjustment 1 (column 3 in the picture) eliminates the feldspar and sources Al2O3 from kaolin and KNaO from Frit 3110 (preserving the glaze's chemistry). To make that happen the amounts of other materials had to be juggled. But the fired test revealed that this one, although very similar, is melting more (because the frit releases its oxides more readily than feldspar). Adjustment 2 (column 4) proposes a 10-part silica addition. SiO2 is the glass former, the more a glaze will accept without losing the intended visual character, the better. The result is less running and more durability and resistance to leaching.

Pages that reference this post in the Digitalfire Reference Library:

Ferro Frit 3110, SiO2, KNaO, Where do I start in understanding glazes?, Glazes of the same chemistry: The fritted one melts better, High feldspar glazes craze. Don't put up with it., A down side of high feldspar glazes: Crazing!, Click here for case-studies of Insight-Live fixing problems, GLC - Glaze Chemistry, Limit Recipe, Frit, Leaching, Glaze Chemistry, Runny Ceramic Glazes

This post is one of thousands found in the Digitalfire Reference Database. Most are part of a timeline maintained by Tony Hansen. You can search that timeline on the home page of digitalfire.com.