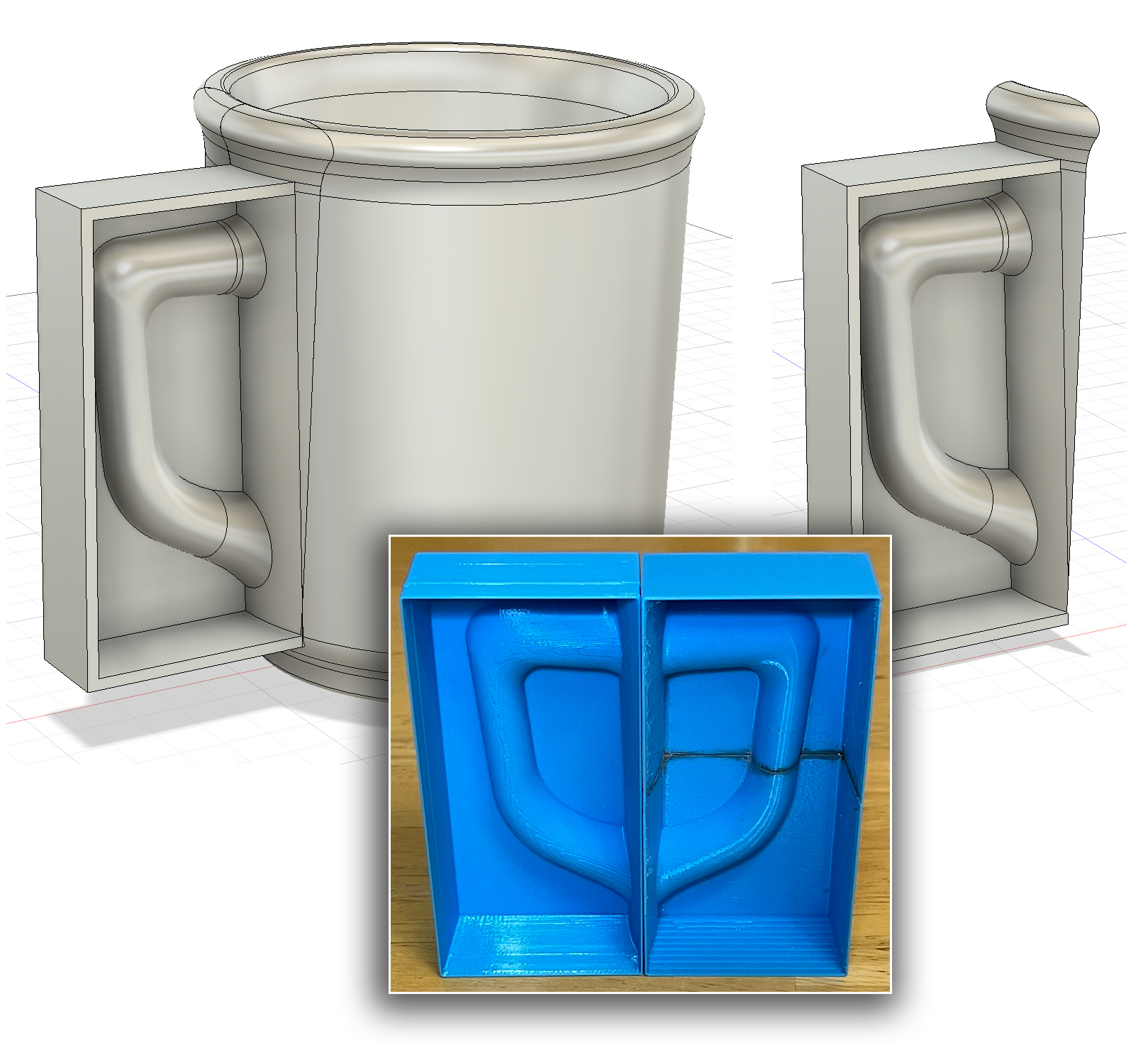

The incredible utility of 3D-printing handle case molds

These molds are insight-live.com/glossary/267">3D-printed from PLA filament. They are part of my 2019 year-long casting-jiggering project to reproduce a Medalta 66 mug. A quick soaping, 325g water, 475g plaster and a fifteen-minute set produced these two plaster molds. When casting these solid they can be ready to apply in an hour after pouring (using the slip clays I have). While it is amazing how well these molds work I learned several things about them for version 2.0. The two halves mate with a tiny amount of play, it was better not to have the natches, that enabled sanding the mating surfaces flat for a perfect fit (simply lining up the outsides lines up the insides). Spares are not needed either, a 3D-printed dual pour spout worked better. A draft on the side walls also made it easier to get the plaster molds out after they set (these don’t have to be removed with the heat gun because of the round handle cross section).

Pages that reference this post in the Digitalfire Reference Library:

Final cast-jiggered cone 6 mug beside original 3D-printed mock-up, My first 3D-printed handle case mold, Poor plaster release from 3D printed mug handle case molds, 2019 Jiggering-Casting Project of Medalta 66 Mug, Mug Handle Casting

This post is one of thousands found in the Digitalfire Reference Database. Most are part of a timeline maintained by Tony Hansen. You can search that timeline on the home page of digitalfire.com.