Polish the plaster surface, not the 3D-printed shell-mold

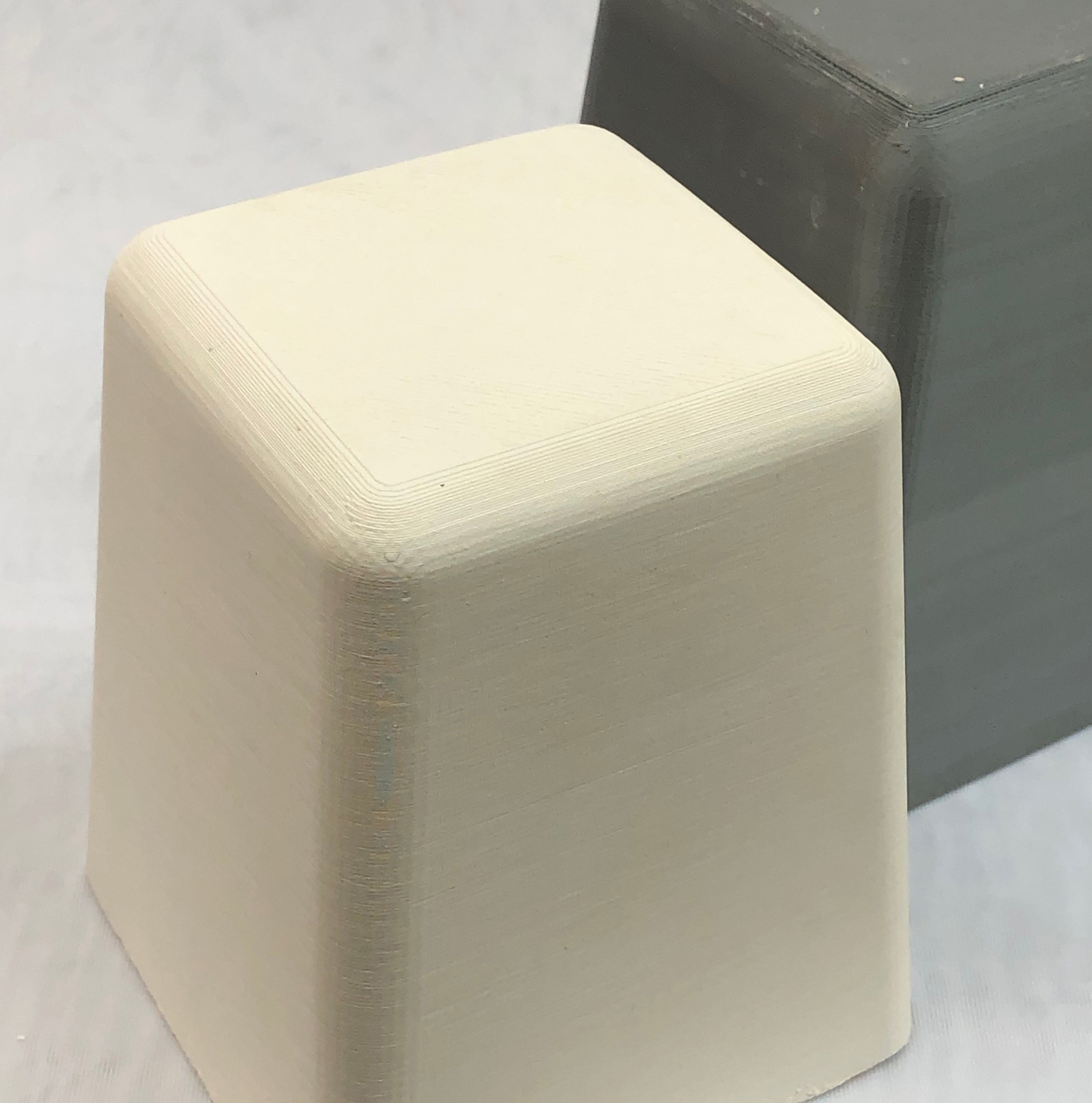

This plaster model was just removed from the insight-live.com/glossary/267">3D-printed shell behind. It dropped out easily (after tapping it at-an-angle on the corners), this worked well despite the resolution lines on the surface. While I could have spent time sanding and smoothing the inside of the shell-mold, it is actually far easier to smooth the surface of the plaster form after extraction. Seconds with a metal rib completely smooths any of the surfaces. And remember, it is easier to remove plaster items cast inside of 3D-printed molds rather than cast around the outside of them. I named this size as 95-5-113, referring to the TopWith-Angle-Height. I set these as parameters in Fusion 360 and can print adjustments to this size (labelling them appropriately).

This post is one of thousands found in the Digitalfire Reference Database. Most are part of a timeline maintained by Tony Hansen. You can search that timeline on the home page of digitalfire.com.