You may know Veegum T but do you know VeeGum CER?

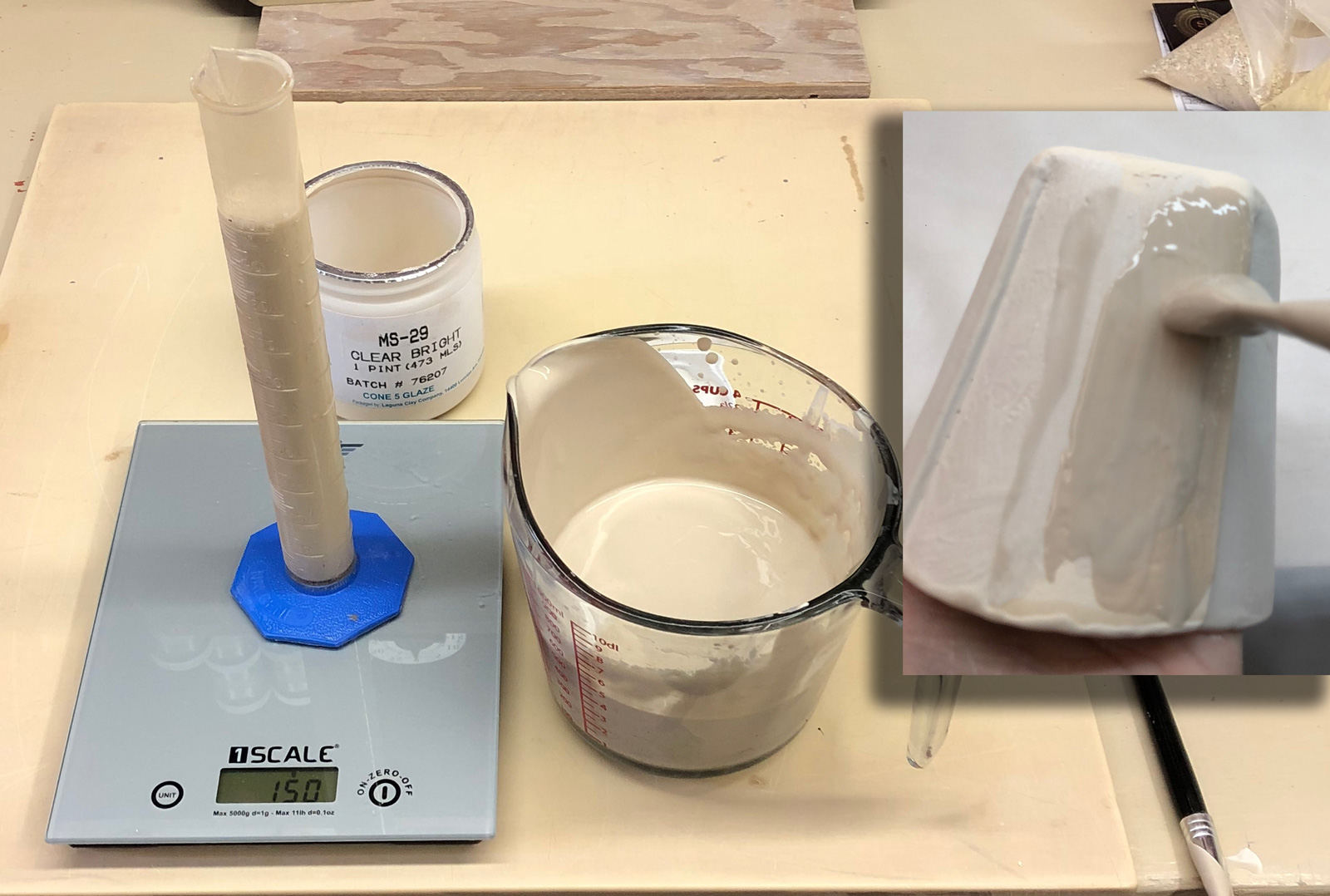

The glaze in this jar was 'goop', impossible to paint on because it was too viscous. And it dried way too fast. Laguna mentions adding water so I measured the specific gravity (SG): 1.7. That is super-high, it took a 125cc addition to bring it down to 1.5, but it was still thick, dried even faster, and brushing it on evenly was even harder. It was not obvious what to do next. It needed a lot more water (1.3-1.35 SG is normal for multi-layer application of insight-live.com/glossary/290">low SG glazes), adding CMC gum and enough water to do that would produce an unusable watery and sticky slurry. Veegum CER to the rescue! It is a 50:50 mix of CMC gum and Veegum T. The former slows drying and hardens, the latter gels. So it can simply be added until the painting properties are right. And, a Veegum CER solution is easier to handle than one of CMC gum. The brushing properties are just right, it gels nicely on standing and stays in place on verticals. CER is also good for highly fritted dipping glazes or others lacking in clay content (otherwise CMC might still be better).

Pages that reference this post in the Digitalfire Reference Library:

Veegum, Veegum CER Saturated suspension, Base-Coat Dipping Glaze, Brushing Glaze

This post is one of thousands found in the Digitalfire Reference Database. Most are part of a timeline maintained by Tony Hansen. You can search that timeline on the home page of digitalfire.com.