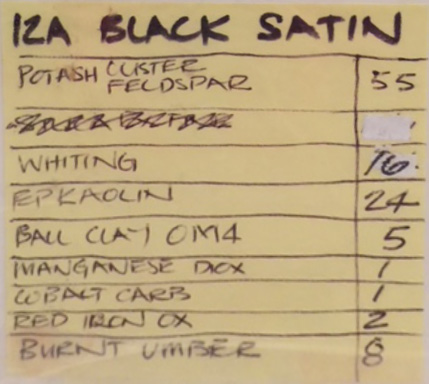

From Scribbles to Success: Fixing This Glaze Recipe

If you do DIY pottery glazing you may have recipes scribbled onto cards like this. But the card is not the big issue here, it is that recipe! It really needs some work. Here is what could be done.

-Add this as a recipe in an account at insight-live.com (and assign it a code number) to start a testing project. Along the way document it with pictures, firing schedules, general notes, etc.

-With all that feldspar it is sure to craze, reducing the high thermal expansion K2O it contributes in favor of low expansion MgO (from talc) is the most likely fix.

-With all that clay (29 total) it is likely to crack while drying (and then crawl during firing), split it into part calcined kaolin and part raw kaolin (the ball clay is not needed).

-And those colorants: It is better to use cobalt oxide than carbonate. Perhaps the burnt umber could be increased to eliminate the need for both the manganese and iron (since it supplies both and has zero LOI). Better yet, remove all four and use a black stain (7% would likely be enough).

Pages that reference this post in the Digitalfire Reference Library:

Calcined Kaolin, Are Your Glaze Recipes Lost in Binders or Buried on Your Phone?, GLC - Glaze Chemistry, Digitalfire Insight

This post is one of thousands found in the Digitalfire Reference Database. Most are part of a timeline maintained by Tony Hansen. You can search that timeline on the home page of digitalfire.com.