Frits vs. raw materials in glazes: It is not just about the chemistry

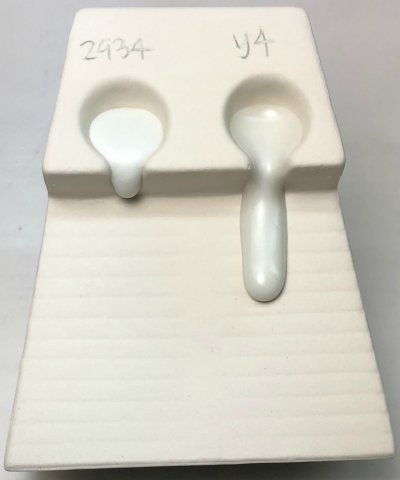

The difference between sourcing fluxing insight-live.com/glossary/67">oxides from frits vs. raw materials is significant to say the least. The oxides MgO and CaO normally come from natural mineral that melt high. But common frits that source them soften low. The chemistry in the two cone 6 glazes (compared on this melt flow tester) are the same. But G2934Y4 sources the KNaO from Ferro Frit 3110 instead of feldspar and alot of the MgO from Ferro Frit 3249 instead of talc. Even though Y4 has 10% calcined alumina it still flows much better! Alumina, as a source of Al2O3, is a super refractory material (compared to kaolin, the normal source), the glaze should flow less - but the frits overcome even that to create this amazing fluidity in a matte glaze. The lesson: All glazes have a chemistry, but that cannot be taken in isolation from the materials that source it. Glaze chemistry is a relative, not absolute science.

Pages that reference this post in the Digitalfire Reference Library:

Ferro Frit 3110, Ferro Frit 3249, The Seger Unity Formula, Glaze Chemistry, Frit, Melt Fluidity

This post is one of thousands found in the Digitalfire Reference Database. Most are part of a timeline maintained by Tony Hansen. You can search that timeline on the home page of digitalfire.com.