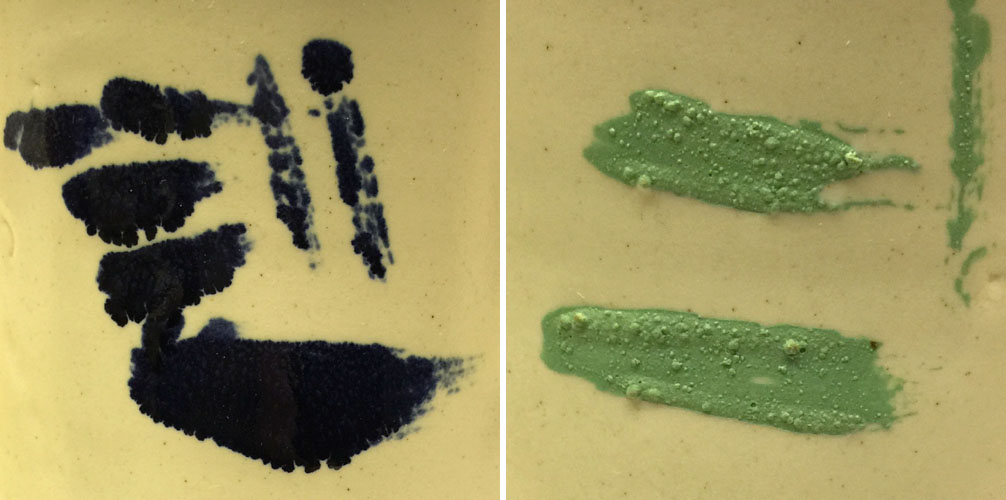

Why you should not paint pure stain powders over glaze

On the left is a pure blue stain, on the right a green one. Obviously, the green is much more insight-live.com/glossary/76">refractory. On the other hand, the green just sits on the surface as a dry, unmelted layer. For this type of work, stains need to be mixed into a glaze-like recipe of compatible chemistry (a medium) to create a good, paintable color. The blue is powerful, it would only need to comprise 5-10% of the recipe total. Its medium would need to have a stiffer melt (so the cobalt fluxes it to the desired degree of melt fluidity). A higher percentage of the green stain is needed, perhaps double. It's medium needs much more melt fluidity since the stain is refractory. Of course, only repeated testing would get them just right. Guidelines of the stain manufacturer for chemistry compatibility need to be consulted also (as certain stains will not develop their color unless their glaze medium host has a compatible chemistry). And, to be as paintable as possible, use use a gum-solution/water mix (e.g. 2 parts water to one part gum solution).

Pages that reference this post in the Digitalfire Reference Library:

An Overview of Ceramic Stains, Why it is not a good idea to use straight stain, Ceramic Stain, Overglaze, Flux, Refractory, Bleeding colors

This post is one of thousands found in the Digitalfire Reference Database. Most are part of a timeline maintained by Tony Hansen. You can search that timeline on the home page of digitalfire.com.