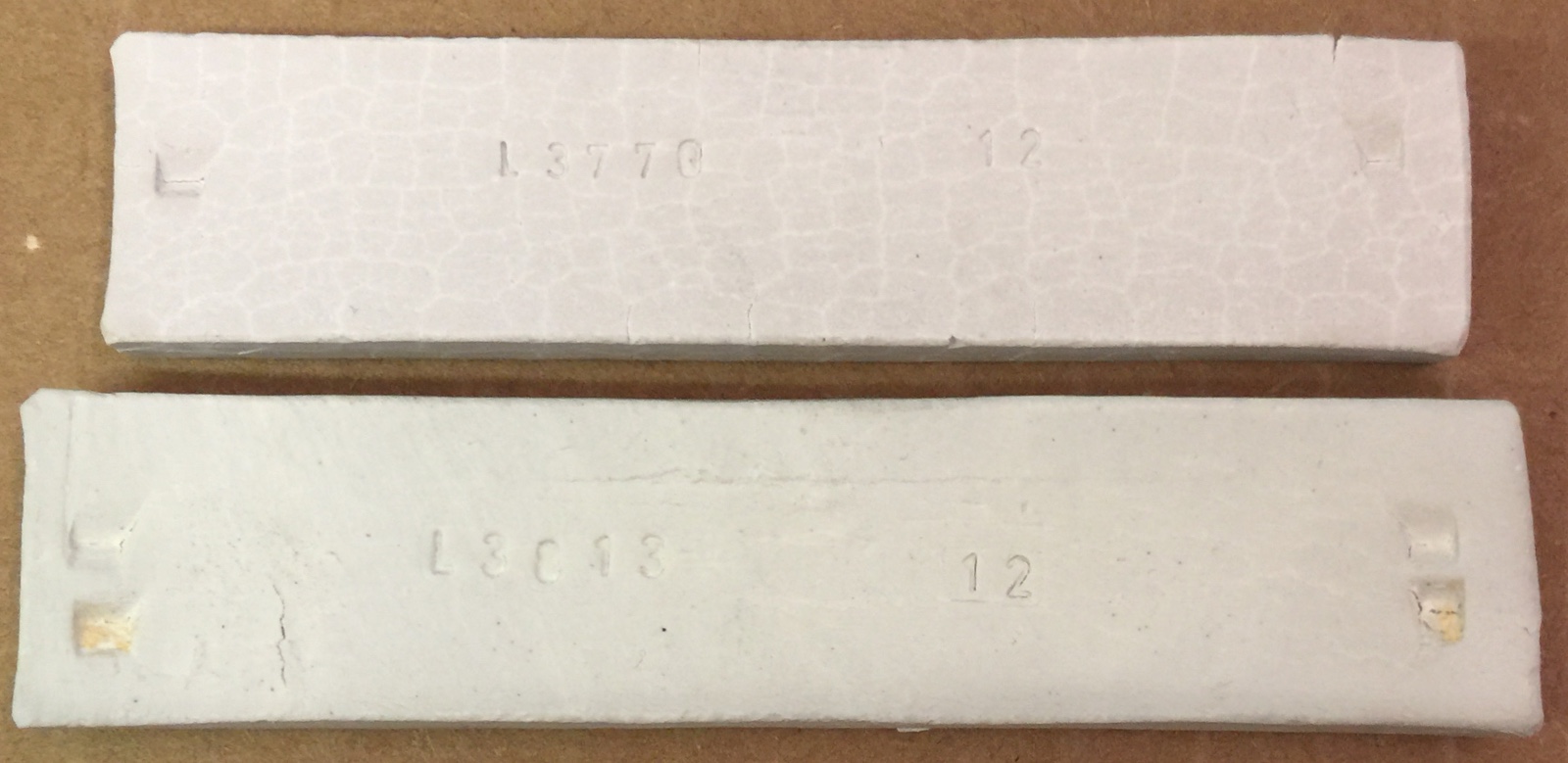

EPK fired bar (top) vs Grolleg kaolin at cone 10R. Why shrinking more?

From these SHAB test bars EP insight-live.com/material/925">kaolin appears to have a much higher fired shrinkage. But half of that happened during drying. Still, EPK shrinks 4% more during firing. Yet Grolleg produces more vitrified porcelains. The EPK bar also appears to be whiter. Yet in a porcelain body, Grolleg fires whiter. That higher drying shrinkage proves that EPK is much more plastic, right? Not really. Throwing porcelains containing either require plasticity augmentation using similar percentages of bentonite. What do we learn? To compare materials like this we need to see them "playing on the team", in a recipe working with other materials. Don't rely on material data sheets, do the testing in your recipes.

Pages that reference this post in the Digitalfire Reference Library:

Grolleg Kaolin, EP Kaolin, Thrown pieces made from pure Grolleg and EP kaolins This is how you compare plasticities, What makes EP Kaolin unique? Are others as good?

This post is one of thousands found in the Digitalfire Reference Database. Most are part of a timeline maintained by Tony Hansen. You can search that timeline on the home page of digitalfire.com.