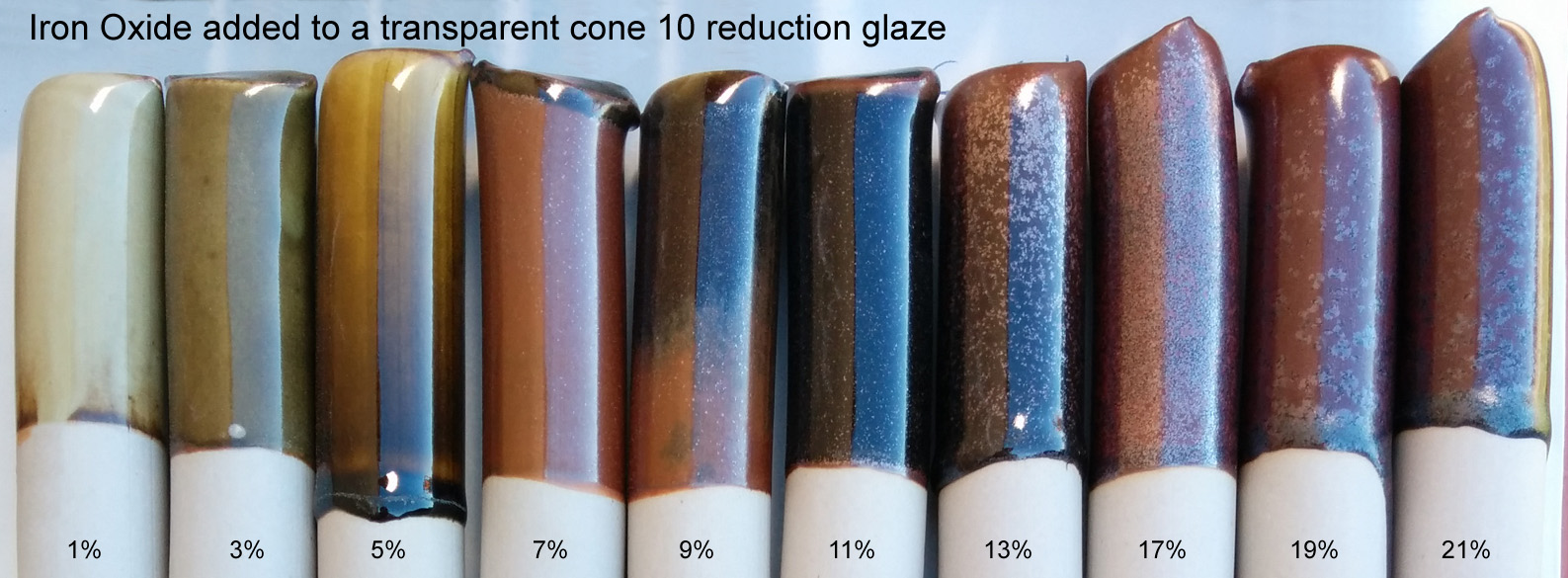

Additions of iron oxide are coloring, fluxing and crystallizing this base transparent

insight-live.com/material/874">Iron oxide is an amazing glaze addition in reduction. Here, I have added it to the G1947U transparent base. It produces green celadons at low percentages. Still transparent where thin, 5% produces an amber glass (and the iron reveals its fluxing power). 7% brings opacity and tiny crystals are developing. By 9% color is black where thick, at 11% where thin or thick - this is “tenmoku territory”. 13% has moved it to an iron crystal (what some would call Tenmoku Gold or Teadust), 17% is almost metallic. Past that, iron crystals are growing atop others. These samples were cooled naturally in a large reduction kiln using the C10RPL firing schedule, the crystallization mechanism would be heavier if it were cooled more slowly (or less if cooled faster). The 7% one in this lineup is quite interesting, a minimal percentage of cobalt-free black stain could likely be added to create an inexpensive and potentially non-leaching jet-black glossy.

Pages that reference this post in the Digitalfire Reference Library:

Iron Oxide Red, Same iron red glaze on black stoneware and on porcelain, A cone 10R high iron glaze has run off the vase during firing. And crystallized., A way to prevent a tenmoku glaze from running onto your kiln shelves, FeO (iron oxide) is a very powerful flux in reduction, Metallic Glazes, Mechanism, Crystallization, Tenmoku, Celadon Glaze, Reduction Firing

This post is one of thousands found in the Digitalfire Reference Database. Most are part of a timeline maintained by Tony Hansen. You can search that timeline on the home page of digitalfire.com.