Making your own crucibles to make your own speckle

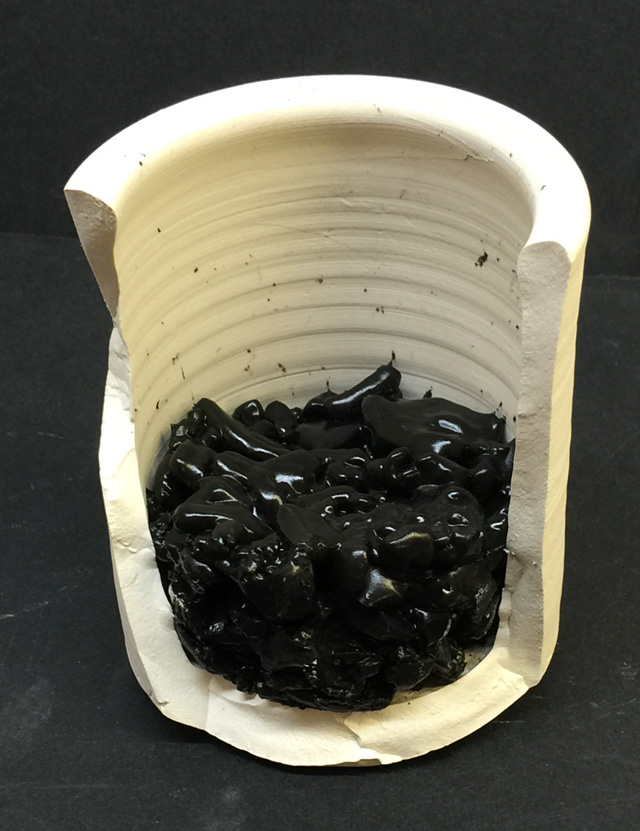

I mixed a cone 6 porcelain body and a cone 6 clear glaze 50:50 and added 10% Mason 6666 black stain. The material was plastic enough to slurry, dewater and wedge like a clay, dry and break into small pieces. I then melted them at cone 6 in a insight-live.com/material/1724">Zircopax crucible (I make these by mixing alumina or zircopax with 3-4% veegum and throwing them on the wheel). This material does not completely melt so it is easy to break the crucible away (it does not stick to the zircon). I then break the black up with a special flat metal crusher we made, size them on sieves and add them to glazes for artificial speckle. If specks fuse too much I can lower percentage of glaze (and vice versa). Of course, the particles are glass, jagged and sharp-edged so care is needed in handling them.

Pages that reference this post in the Digitalfire Reference Library:

Calcined Alumina, A magnesia speckle matte at cone 6 oxidation is impossible, right? Wrong!, Making my own home-made fired speckle for cone 6, Crucible, Reduction Speckle

This post is one of thousands found in the Digitalfire Reference Database. Most are part of a timeline maintained by Tony Hansen. You can search that timeline on the home page of digitalfire.com.