More carbon needs to burn out than you might think!

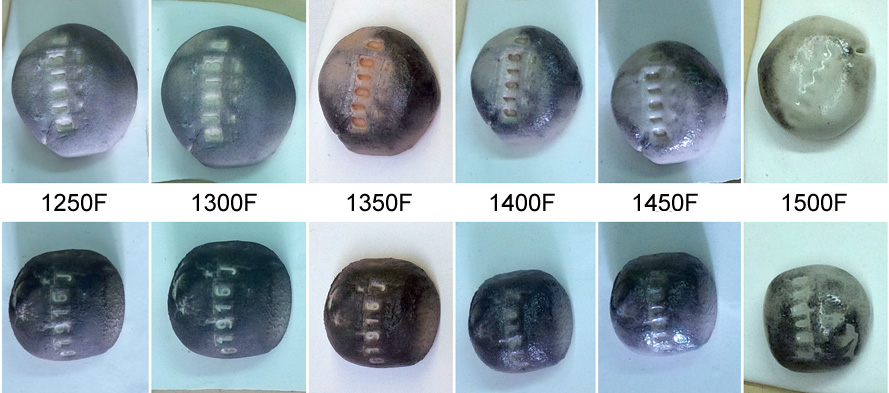

Hard to believe, but this carbon is on ten-gram balls of insight-live.com/glossary/34">low fire glazes having 85% frit. Yes, this is an extreme test because glazes are applied in thin layers, but glazes sit atop bodies much higher in carbon bearing materials. And the carbon is sticking around at temperatures much higher than it is supposed to (not yet burned away at 1500F)! The lower row is G1916J, the upper is G1916Q. These balls were fired to determine the point at which the glazes densify enough that they will not pass gases being burned from the body below (around 1450F). Our firings of these glazes now soak at 1400F (on the way up). Not surpisingly, industrial manufacturers seek low carbon content materials.

Pages that reference this post in the Digitalfire Reference Library:

GBMF Glaze Melt Fluidity - Ball Test, Carbon trap glazes, LOI, Soaking, Carbon Burnout, Firing Schedule

This post is one of thousands found in the Digitalfire Reference Database. Most are part of a timeline maintained by Tony Hansen. You can search that timeline on the home page of digitalfire.com.