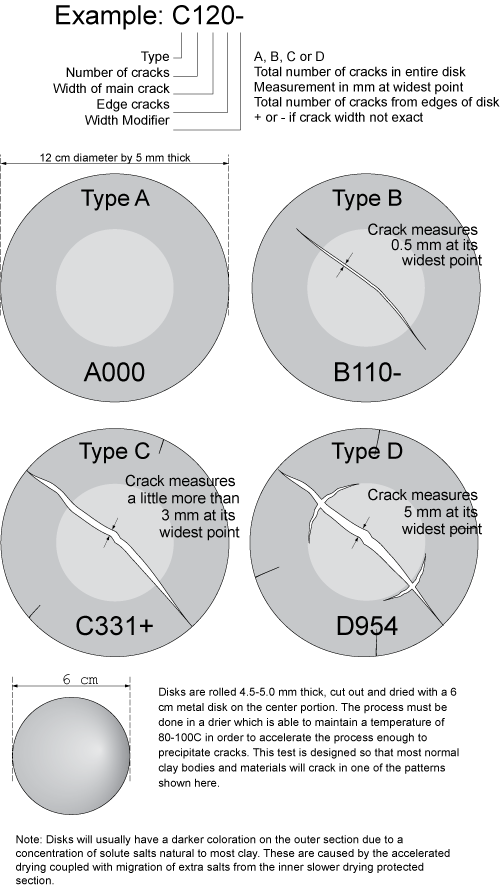

How to interpret the crack in a DFAC drying disk

Drying disks used for the DFAC test are 12cm in diameter and 5mm thick (wet). A crack pattern develops in almost all common pottery clays as they shrink during drying. This happens because the center portion is covered and stays soft while the perimeter dries hard. This sets up a tug-of-war with the later-drying inner section pulling at the outer rigid perimeter and forcing a crack (starting from the center). If the clay has high plasticity and dry strength it can pull so hard from the center that cracks appear at the outer dried edge to relieve the tension. Or, it can create cracks that run parallel to the outer edge but at the boundary between the inner and outer sections. The nature, number and width of the cracks are interpreted to produce a drying factor that can be recorded.

Pages that reference this post in the Digitalfire Reference Library:

DFAC Drying Factor, Drying Ceramics Without Cracks, Drying Performance, Drying Shrinkage

This post is one of thousands found in the Digitalfire Reference Database. Most are part of a timeline maintained by Tony Hansen. You can search that timeline on the home page of digitalfire.com.