Paper clay is easy to make. And really different!

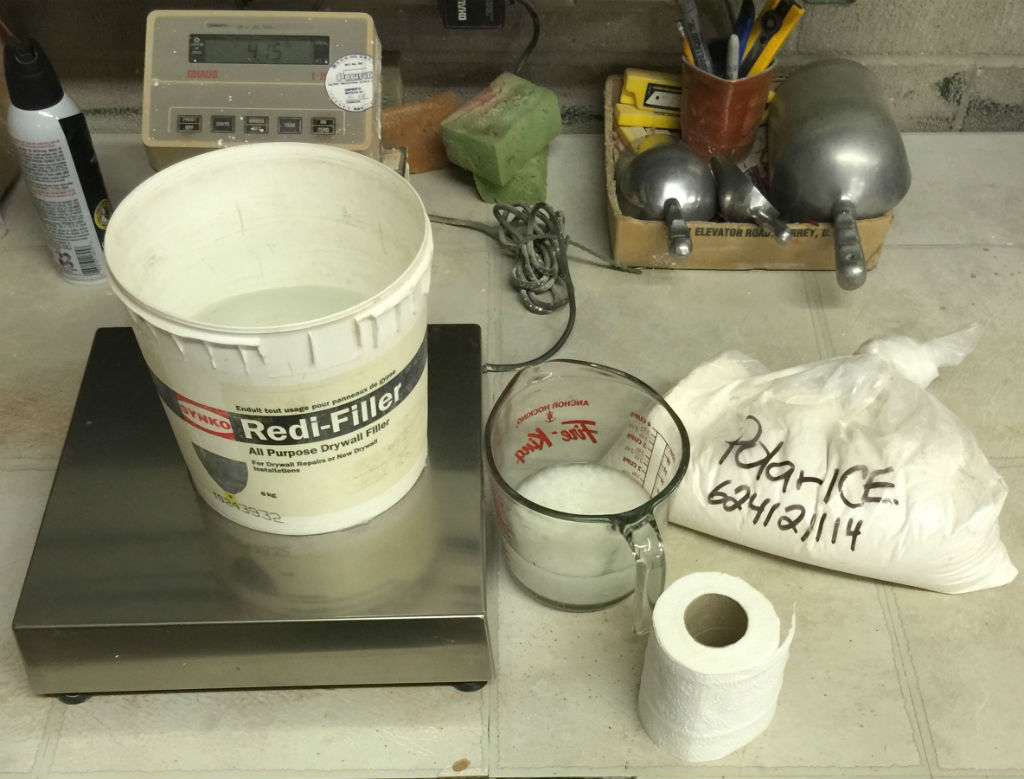

This measuring cup contains 30 squares of toilet paper or 11 grams (which has disintegrated quickly and has been propeller-mixed). I am about to dump the paper fiber and 1000 grams of plastic porcelain powder into the water and then mix that up and pour the slurry onto a plaster bat. Although the fiber is only 1% by weight of the dry mix, this completely changes the working properties of the clay. It is still plastic, but much more difficult to cut with a knife or wire. It rolls out nicely into very thin slabs and they are very tough and easy to manipulate and build with. As it hardens it is still pretty plastic.When forced to bend it slowly breaks as the fibers release across the boundaries. Two dry pieces of this clay can be joined using only water and they stick together! Of course this paper needs to burn out during firing, so you need good ventilation on your kiln. You might think that this paper clay shrinks much less than the non-paper version. Actually, it shrinks more (likely because of the increased percentage of water needed). The paper is imparting strength, that strength is enough to resist cracking on drying.

Pages that reference this post in the Digitalfire Reference Library:

Fibers visible along a broken edge of a dried paper clay slab, Powder to slurry to dewatered to mugs with handles in 1 hour. How?, Green Strength

This post is one of thousands found in the Digitalfire Reference Database. Most are part of a timeline maintained by Tony Hansen. You can search that timeline on the home page of digitalfire.com.