I want this engobe to gel in ten seconds. Why?

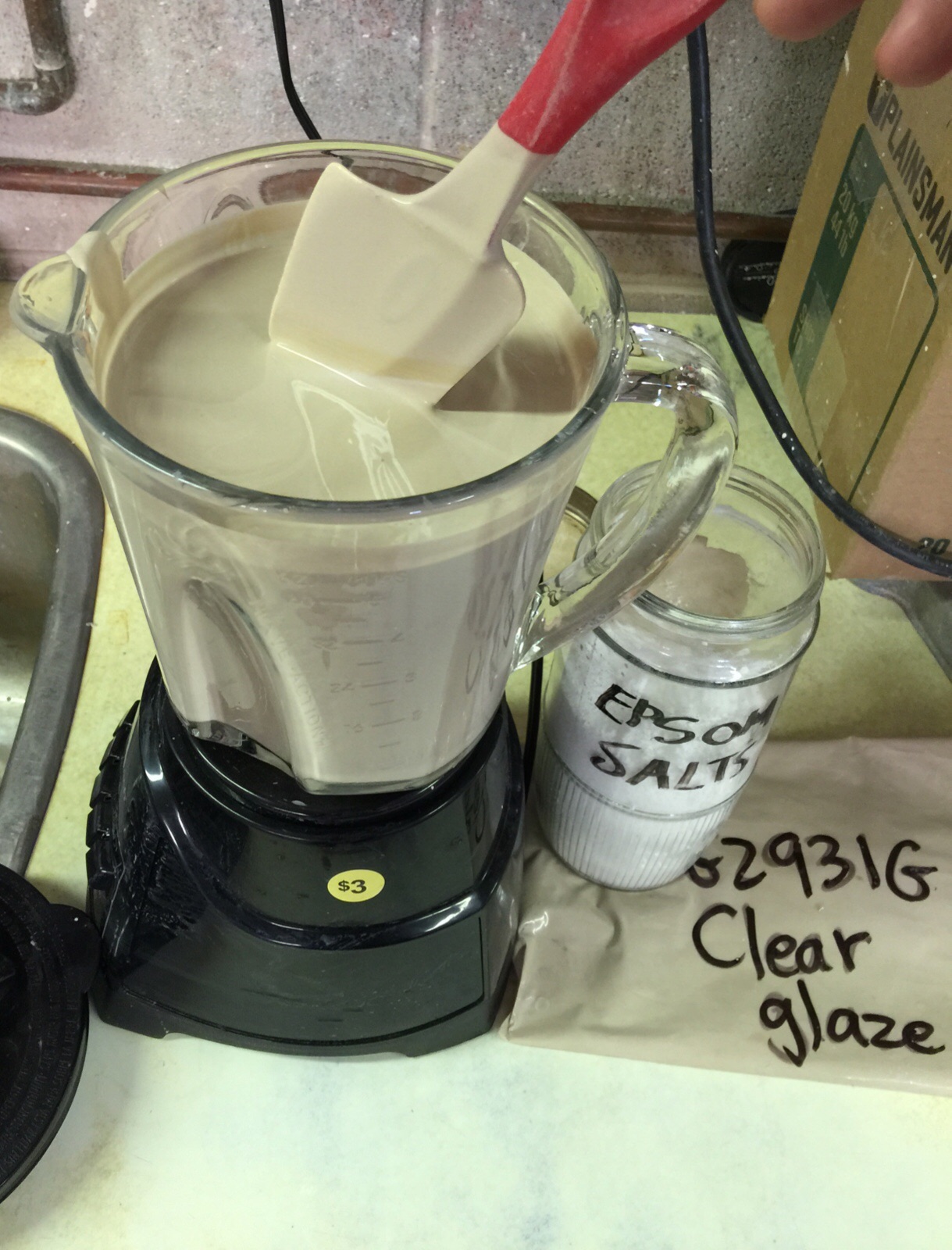

It is going to be applied to leather hard earthenware and it needs to be insight-live.com/glossary/91">thixotropic (gelled when not in motion, liquid when in motion). Why? I do not want it to run down from the rims of the mugs after dipping. The process: Stir the engobe, pour-fill the mug, pour it out and push it upside down into the engobe. If I can pull it back out before the 10 second gel-time is up I get a perfectly even layer that does not move. A good test is to stir it then pull out the spatula slowly. If it hangs on in a even layer with only a few drips it is perfect. Achieving this behaviour requires very careful additions of powdered epsom salts (and thorough mixing between). As the slip approaches this 10 second threshold even a slight bit more salts will turn it into a bucket of jelly (if that happens I add a drop or two of Darvan). This process works across a range of specific gravities (about 1.45-1.6), the higher the SG the trickier it is (but the faster it dries).

Pages that reference this post in the Digitalfire Reference Library:

This post is one of thousands found in the Digitalfire Reference Database. Most are part of a timeline maintained by Tony Hansen. You can search that timeline on the home page of digitalfire.com.