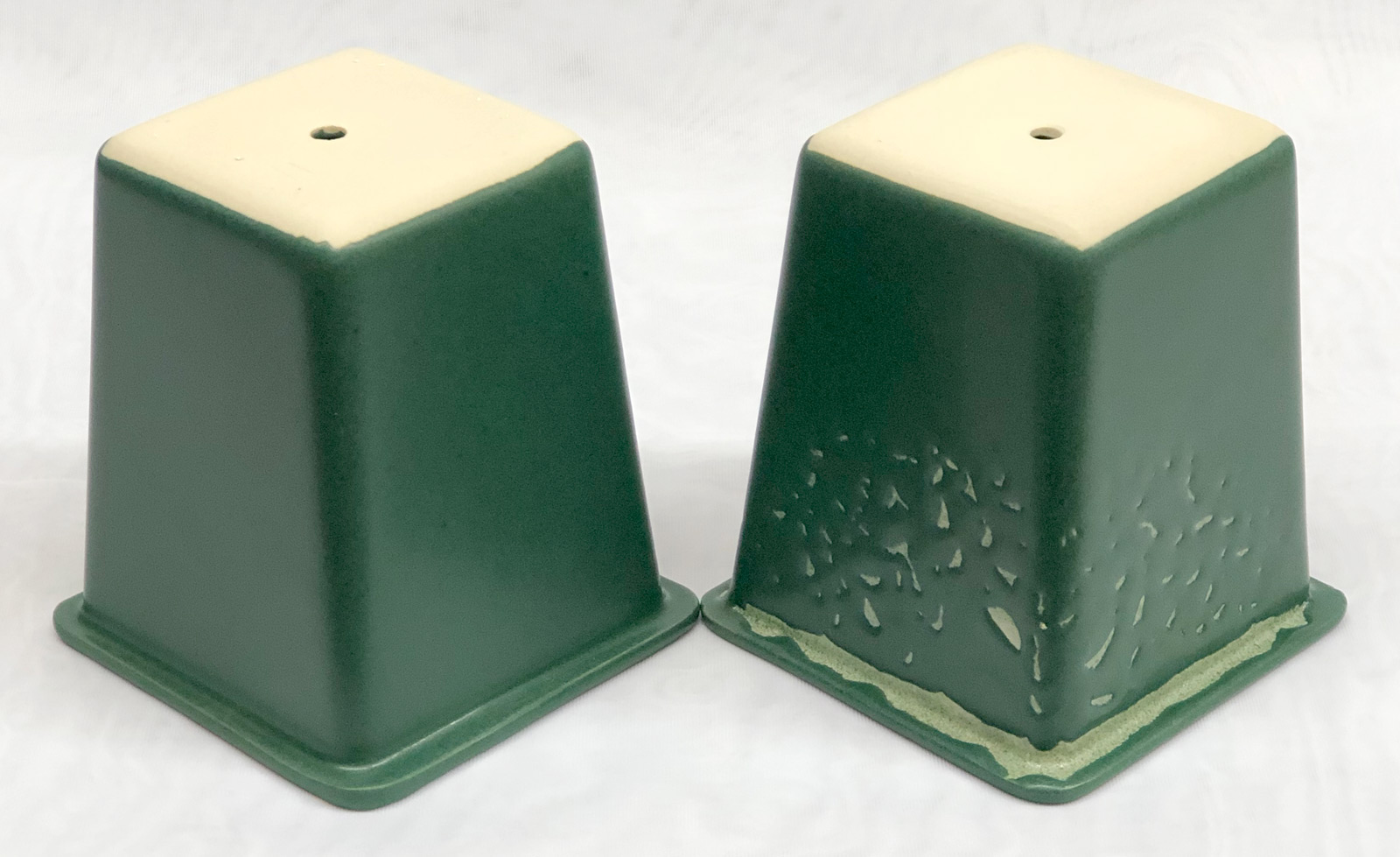

Same body, same glaze, same firing. Why did one crawl?

The body: M370. Glaze: G2934Y (with added green stain). Firing: Cone 6 insight-live.com/glossary/289">drop-and-hold. Glazing method: dipping (using tongs). Thickness: The same. Surface: Clean on both. The difference: Clay wall thickness. The one on the right was cast much thinner so the glaze took a lot longer to dry. Common pottery glazes contain clays which need to shrink somewhat during drying. The bond with the bisque, although fragile, is normally enough to prevent cracking during drying. But drying needs to occur quickly with glazes containing no gum hardener - that is only possible when the body has enough porosity to absorb all the water quickly. Otherwise, cracks appear - and they become crawls during firing. A complicating factor is that stain and/or zircon additions make an already crawl-susceptible glaze even worse. One or a combination of the following can be done to minimize crawling on even very thin-walled pieces:

-Apply a thinner glaze layer.

-Heat the bisque before dipping.

-Glaze the inside and outside separately (with drying between).

-Deflocculate the glaze to reduce water content.

-Brush or spray on a CMC gummed version in multiple coats.

Pages that reference this post in the Digitalfire Reference Library:

G2934Y - Cone 6 Magnesia Matte Low LOI Version, Crawling in G2934Y Zircopax white glaze: Here are some fixes., Crawling glaze on slip cast ware is common, Crawling

This post is one of thousands found in the Digitalfire Reference Database. Most are part of a timeline maintained by Tony Hansen. You can search that timeline on the home page of digitalfire.com.