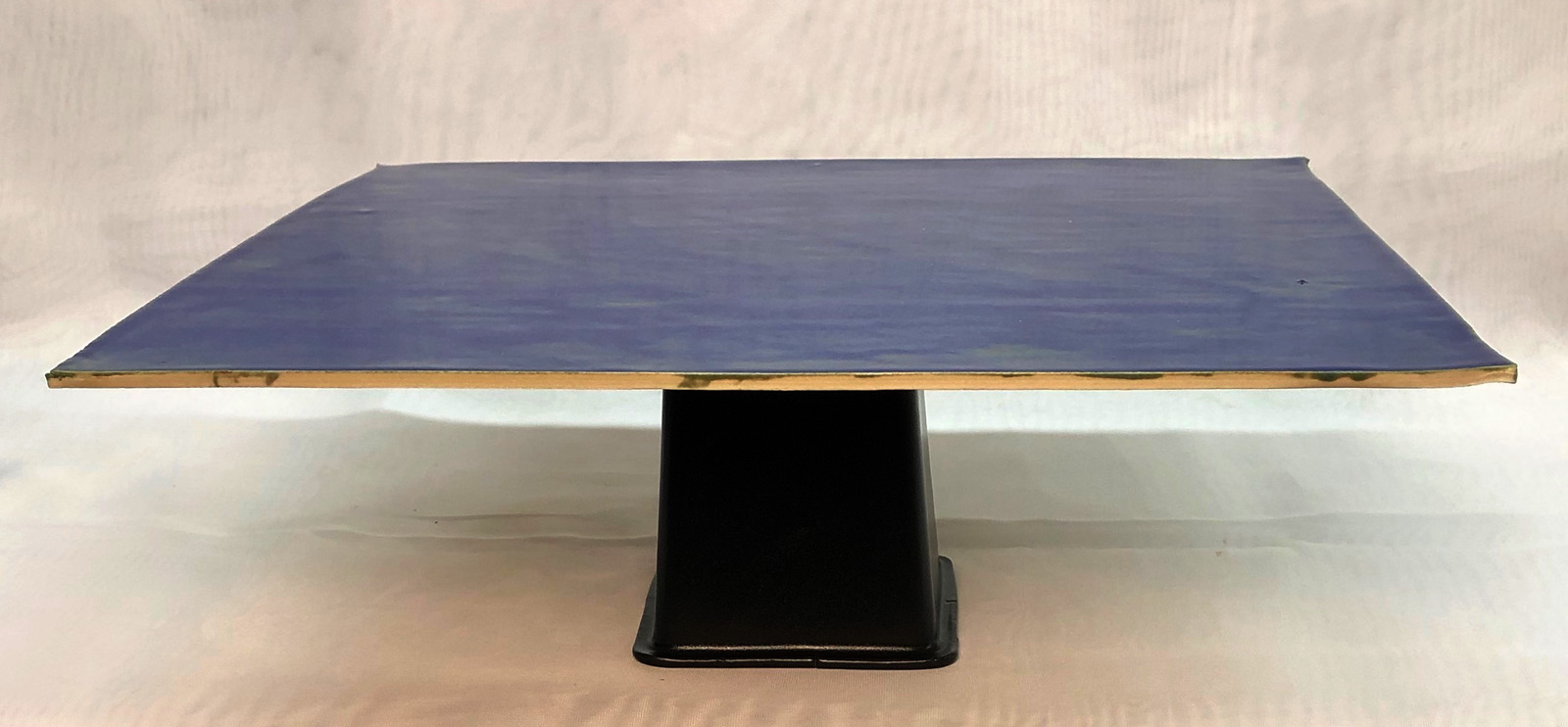

It possible to make a thin flat porcelain tile from a plastic pottery body

Yes. The body is Plainsman M370 (~ 25 insight-live.com/material/1245">silica, 25 feldspar, 30 kaolin, 20 ball clay + talc to tune maturity), a plastic throwing clay with far too much drying shrinkage to be suitable for tile. It is 3.8 mm thick fired (vs. commercial tiles are 5-7mm) and 33cm (13 in) square. It dried absolutely flat between sheets of plasterboard. We have even achieved total flat drying at this size using Polar Ice. Bisque and glaze firing were on an alumina shelf in an electric pottery kiln (at 300F/hr up through quartz inversion on the glaze firing), a completely unsuitable method for firing tile evenly top and bottom. Cooling on both firings was free-fall in a fairly empty kiln. Yet, it is flat! And flexible enough that I could lay it on the cement floor and stand on it without it breaking! Of course, to produce these consistently, special furniture that sinks minimal heat and a kiln that can evenly apply it front and back are needed. This is doable for custom applications. Of course, to compete in the commercial market, they need to be dust-pressed and there are lots of specifications to meet.

Pages that reference this post in the Digitalfire Reference Library:

Ceramic Tile, Making a high quality ceramic tile

This post is one of thousands found in the Digitalfire Reference Database. Most are part of a timeline maintained by Tony Hansen. You can search that timeline on the home page of digitalfire.com.