Particle size drastically affects drying performance

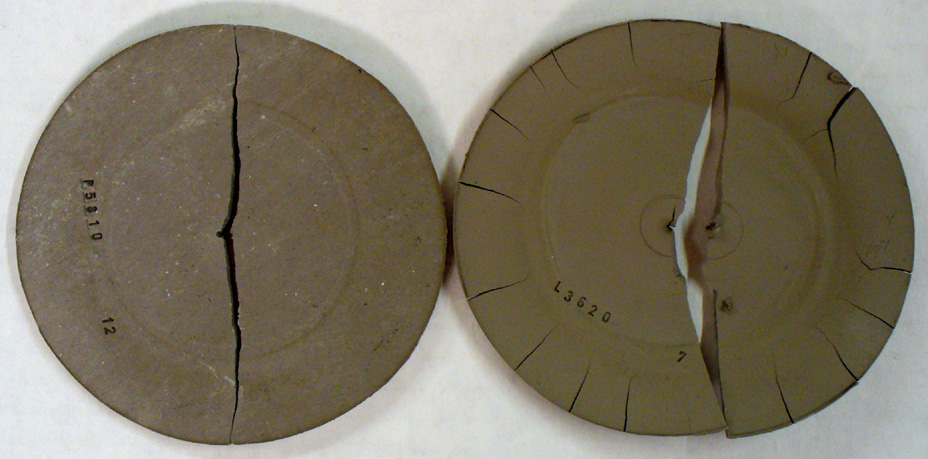

These DFAC testers compare the drying performance of insight-live.com/material/1142">Plainsman A2 ball clay at 10 mesh (left) and ball milled (right). This test dries a flat disk that has the center section covered to delay its progress in comparison to the outer section (thus setting up stresses). Finer particle sizes greatly increase shrinkage and this increases the number of cracks and the cracking pattern of this specimen. Notice it has also increased the amount of soluble salts that have concentrated between the two zones, more is dissolving because of the increased particle surface area.

Pages that reference this post in the Digitalfire Reference Library:

DFAC Drying Factor, Ball milling, Drying Shrinkage, Ball Clay

This post is one of thousands found in the Digitalfire Reference Database. Most are part of a timeline maintained by Tony Hansen. You can search that timeline on the home page of digitalfire.com.