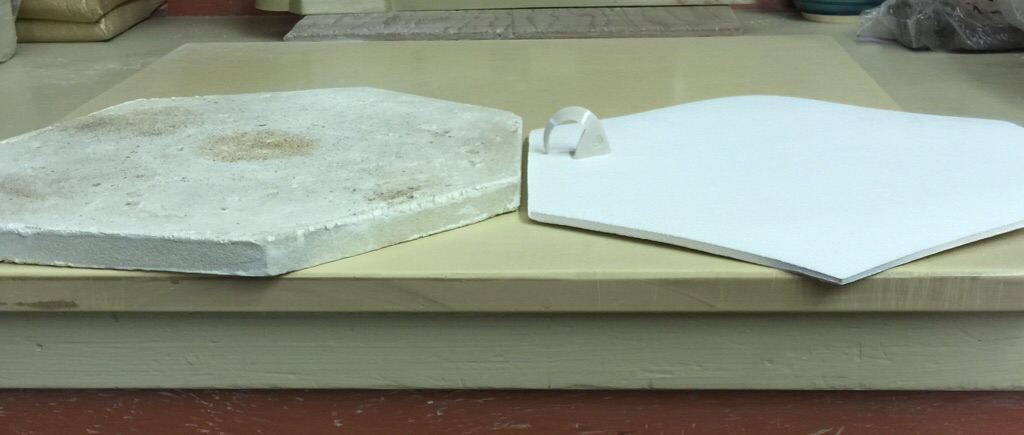

My first zircopax kiln shelf

It is 5 mm thick (compared to the 17mm of the cordierite one). It weighs 650 grams (vs. 1700 grams). It will perform at any temperature that my test kiln can do, and far in excess of that. It is made from a body I slurry up (80% insight-live.com/material/1724">Zircopax Plus, 16.5% 60-80 Molochite grog, 3.5% Veegum T). The body is plastic and easy to roll and had 4.2% drying shrinkage at 15.3% water. The shelf warped slightly during drying (I should have dried it between sheets of plasterboard). Firing at cone 4 yielded a shrinkage of 1%. Notice that cone on the shelf: It has not stuck even though no kiln wash was used! Zircopax is super refractory! This is sinter bonded, so the higher the temperature you can fire the stronger it will be. Although it would be very hard to make full 18 or 22-inch shelves for larger kilns, smaller ones designed to "network" would enable a tighter load of ware with a much lower shelf-to-ware weight ratio (especially using my own lightweight posts). Like alumina, this does not have the thermal shock resistance of cordierite, uneven heating can crack these.

Pages that reference this post in the Digitalfire Reference Library:

Zircopax Plus, Zircopax, Drying a flat slab of clay between sheets of Gyproc, Making your own hexagonal shelves using calcined alumina, Super kiln wash that can be applied with a paint roller, I Just Made These Kiln Posts Using a Hand Extruder Get the v2 CAD drawing to do it yourself, Refractory, Sintering

This post is one of thousands found in the Digitalfire Reference Database. Most are part of a timeline maintained by Tony Hansen. You can search that timeline on the home page of digitalfire.com.