Worthington Cone 06-2 Clear

Gelling, High LOI, Gerstley Borate difficult to sub, High Boron

|

Code # G2931 |

Batch # -2 |

| Materials | Amt |

|---|---|

| Gerstley Borate | 55.000 |

| EPK | 30.000 |

| Silica | 15.000 |

Total:100.00

Auto Unity Formula

|

Si:Al: 5.3:1 6.5 (Molar:6.6) 20.7 Cost 0.34 per kg |

Notes

This recipe is a common Gerstley Borate clear base used from 04 all the way to cone 6! At higher temperatures the recipe trends toward less kaolin to more silica and a little less GB (e.g. 50:20:30).

Attractions its simple make-up and crystal clear fired result (low bubble population). Although it can also fire with clouding, variegation and boron blue depending on thickness, the clay body and firing.

The high boron content of Gerstley Borate, enabling high melt fluidity, make this glaze possible. Potters use it on terra cotta, talc and stoneware bodies that generate lots of gases of decomposition and this can often pass and heal bubbles well. High boron clear glazes like this are known for clouding issues (because of micro bubbles) but this has a low enough surface tension to pass them.

Problems with this recipe:

Obviously, if it melts well already at cone 04 great care is going to be needed at cone 2 to prevent it running onto shelves. Highly melt fluid glazes (that have high boron like this) are also more likely to be leachable and to crystallize on cooling (producing the boron-blue clouds).

Paramount is the dreadful problem of gelling. Even with only 1.4 specific gravity (about equal weights of dry material and water and deflocculation with Darvan) it gels badly. The high water content needed and the nature of GB means that glazed ware dries extremely slowly, the glaze shrinks and cracks during drying and crawls during firing. Gerstley Borate is very plastic, yet to make matters worse, the recipe has an additional 30% clay on top of that! This recipe can actually be thrown on a potters wheel!

The thermal expansion is too low for talc bodies, it will shiver on them.

Pictures

Worthinton Clear at cone 01

On a terra cotta clay at this temperature was has stoneware properties. The fired surface is good.

Worthington Clear vs. Fritted Clear

Worthington (right) flows even better than the fritted glaze and does not have any more entrained bubbles even though it has an LOI of 20%. This is likely because its melting history and behavior is such that its ability handle gases of decomposition from the body and its own materials is so much better.

2931 vs 2931b

On Plainsman L215 cone 02 the original base Worthington Clear has gone on very thin on sides of mug (because of the low specific gravity necessary to prevent it from gelling it is very difficult to get it on thick enough). The fired surface is clear but not as glossy. On the rim it has bubbles. The Ulexite version (G2931B) is glossier, and went on thicker because the slurry is so much easier to use. This glaze is not recommend for L215, the latter contains talc that increases its thermal expansion, putting too much squeeze on this glaze.

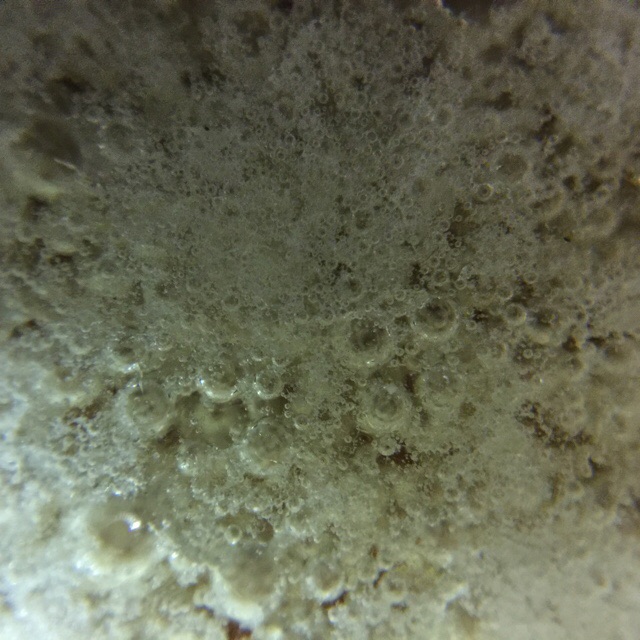

Entrained bubbles in Worthington Clear

This is a 16X closeup of flow test (10 gram ball melted down onto a tile) that concentrates bubbles. There are high populations of large and tiny ones. The larger ones are from the Gerstley Borate, the tiny ones from the kaolin.

GB vs Ulexite Clear glaze bubbles

These are 10 gram balls fired down onto tiles at cone 04 to compare melt fluidity and bubble populations in three clear glazes. Larger bubbles are better, they break at the glaze surface and heal. Tiny ones produce cloudiness.

Left: The original Worthington fluid melt clear glaze recipe. There are clusters of tiny bubbles and many large.

Center: A glaze of the same chemistry but sourcing its boron from Ulexite instead. Notice the lack of tiny bubbles. This fires pretty well identical to the original but has much better slurry properties.

Right: Center with with a 10% addition of lead bisilicate frit. This fires more glossy than either of the other two. Its thermal expansion is also likely lower.

Worthington Clear the next day

Even though this has a low specific gravity and is deflocculated with darvan, the next day it is still jelly. Impossible to use unless more Darvan is added, who knows where that will go!

G2922G, G2931 flow tests

Testdata

SHAB - Shrinkage/Absorption

| DLEN | DSHR | FSHR | ABS | |

| 1 | 92.24 | 7.8% | ||

| 2 | 92.11 | 7.9% |

LDW - LOI/Density/Water Content

| WWGT | DWGT | H2O | LOI | DENS | |

| 1 | 13.52 | 10.26 | 24.1% |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Worthington Cone 06-2 Clear" keywords="Gelling, High LOI, Gerstley Borate difficult to sub, High Boron" id="56711" key="whKhL71x" date="2025-04-06" codenum="G2931" picturebasename=""> <recipelines> <recipeline material="Gerstley Borate" amount="55.000" tolerance=""/> <recipeline material="EPK" amount="30.000" tolerance=""/> <recipeline material="Silica" amount="15.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2014-03-17, Modified: 2025-04-06 20:26:29

Low Expansion Zero3 Clear

|

Code # G2931B |

| Materials | Amt | |

|---|---|---|

| EPK | 25.100 | 25.15% |

| Silica | 10.600 | 10.62% |

| Ulexite | 26.500 | 26.55% |

| Ferro Frit 3249 | 16.900 | 16.93% |

| Wollastonite | 15.500 | 15.53% |

| Nepheline Syenite | 5.200 | 5.21% |

Total:99.80

Auto Unity Formula

|

Si:Al: 5.3:1 6.5 (Molar:6.6) 13.2 Cost 0.29 per kg |

Notes

This is a lower expansion version of G2931K, an ultra-clear for porcelain and talc bodies at low fire. This sacrifices some surface brilliance for the low thermal expansion. The chemistry of this recipe cannot be produced using common frits, the Ulexite is essential (to source the high boron).

The original recipe from which this was derived, Worthington Clear, was high in Gerstley Borate and made a jellied mess in the bucket, very difficult to use. This has the same chemistry but a very different recipe having much better slurry properties.

Do not try to use this with too little water. Mix it to 1.4 specific gravity and add vinegar or Epsom salts to gel it so that it stops moving (after vigorous stirring) in less than 2 seconds. It naturally gels so little vinegar should be needed. It applies very well to low or high porosity bisque (in a very thin layer if needed), it does not drip or move but does take a minute to dry.

The soak:soak:slowdrop firing schedule is critical to a defect-free surface.

Although this recipe has more ingredients than Worthington clear, the range of properties and chemistry they supply presents many more adjustment possibilities.

Pictures

Ulexite Worthington clear cone 02

This is a terra cotta stoneware body, the body contains enough frit to produce 1% porosity at cone 02. Although it appears to work well, it is under too much compression because its thermal expansion is too low. We noted a tendency to shiver on the rims of mugs, especially with the white engobe present.

Worthington Original vs. Ulexite varitation flow test

Gas generation during melt is obviously more active in the Gerstley Borate version (left) than in the Ulexite version (right). This is fired to cone 03.

Ulexite Worthington Clear to cone 02

No pinholes, thin application. Some bubbles. This was fired to temperature and soak 10 minutes (and cool of 100 degrees and soak there would have yielded even better results). Cone 03 and 02 do produce a more brilliant result than cone 04.

2931 vs 2931b

On Plainsman L215 cone 02 the original base Worthington Clear has gone on very thin on sides of mug (because of the low specific gravity necessary to prevent it from gelling it is very difficult to get it on thick enough). The fired surface is clear but not as glossy. On the rim it has bubbles. The Ulexite version (G2931B) is glossier, and went on thicker because the slurry is so much easier to use. This glaze is not recommend for L215, the latter contains talc that increases its thermal expansion, putting too much squeeze on this glaze.

Entrained bubbles in Ulexite Worthington

16x photo of a 10 gram glaze ball melted down onto a tile, it was fired to cone 03. This has both the large and small bubbles populations.

GB vs Ulexite Clear glaze bubbles

These are 10 gram balls fired down onto tiles at cone 04 to compare melt fluidity and bubble populations in three clear glazes. Larger bubbles are better, they break at the glaze surface and heal. Tiny ones produce cloudiness.

Left: The original Worthington fluid melt clear glaze recipe. There are clusters of tiny bubbles and many large.

Center: A glaze of the same chemistry but sourcing its boron from Ulexite instead. Notice the lack of tiny bubbles. This fires pretty well identical to the original but has much better slurry properties.

Right: Center with with a 10% addition of lead bisilicate frit. This fires more glossy than either of the other two. Its thermal expansion is also likely lower.

G2931B and F fit different bodies

The fritted vitreous body on the left shivers using G2931B. The same body (having the same white slip (G3685U) does not shiver the G2931F version of the glaze (it has more KNaO).

Links with Schedules

To: Cone 03 hold-rise-drop-hold

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Low Expansion Zero3 Clear" id="56872" key="Hrz5Bv6B" date="2017-06-08" codenum="G2931B" picturebasename=""> <recipelines> <recipeline material="EPK" amount="25.100" tolerance=""/> <recipeline material="Silica" amount="10.600" tolerance=""/> <recipeline material="Ulexite" amount="26.500" tolerance=""/> <recipeline material="Ferro Frit 3249" amount="16.900" tolerance=""/> <recipeline material="Wollastonite" amount="15.500" tolerance=""/> <recipeline material="Nepheline Syenite" amount="5.200" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2014-03-19, Modified: 2017-06-08 21:20:13