Project Name

PV Clay Substitutes

Project Codenumber

UnAssigned

Notes

PV clay is a plastic feldspar from California, it has long been used in ceramics, mostly at low temperatures to produce white casting bodies. It is also employed in the recipes of many stoneware and even porcelain bodies. And in glazes. However, the manufacturer does not maintain its chemistry, therefore different shipments have different working and firing properties. The difference can be drastic. We chose as a target, the most plastic and vitreous version of PV clay shipments that we have received in the past.

This project is the culmination off many previous attempts to create a duplicate. However this version is the product of a reset to a chemistry match recipe, then adjusting that toward a physical properties match. By "physical properties" we mean plasticity, fired shrinkage, fired porosity, fired color, firing range, etc.

In the coming months we will add a before-and-after physical properties report of an example clay body in which this has been substituted for PV Clay.

PV CLAY Feb 2013 Shipment

|

Code # L3664A |

Location BOX35 |

Batch # -2 |

| Materials | Amt |

|---|---|

| PV Clay | 100.000 |

Total:100.00

|

Si:Al: 10.2:1 5.9 (Molar:5.3) 2.8 |

Notes

Properties:

Fired shrinkage continues upward until it melts

Hits zero-porosity around cone 4

Moderate plasticity, enough to easily make test bars (if not too soft).

Works well for casting.

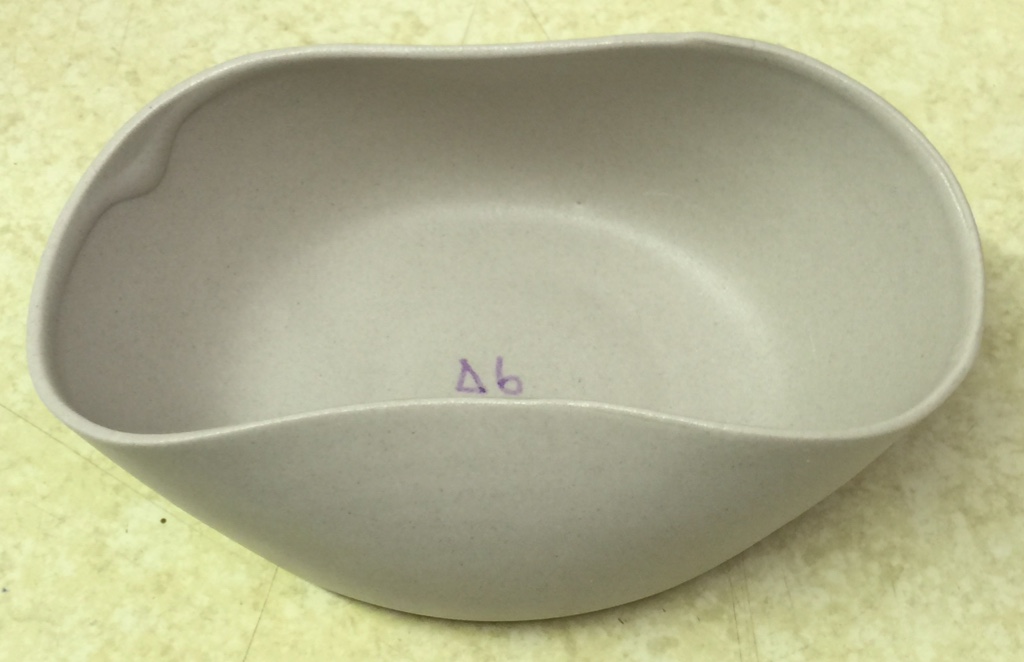

Pictures

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 5 | 95.24 | 85.64 | 39.1 | 39.22 | 4.8 | 4.8% | 10.1% | 0.3% |

| 4 | 94.75 | 85.39 | 39.45 | 39.53 | 4.0 | 5.3% | 9.9% | 0.2% |

| 3 | 95.16 | 86.44 | 40.06 | 41.83 | 3.0 | 4.8% | 9.2% | 4.4% |

| 2 | 94.56 | 89.09 | 38.22 | 42.64 | 2.0 | 5.4% | 5.8% | 11.6% |

| 1 | 94.67 | 89.73 | 38.94 | 43.51 | 1.2 | 5.3% | 5.2% | 11.7% |

| 6 | 95.19 | curled | melting | 4.8% |

LDW - LOI/Density/Water Content

| WWGT | DWGT | FWGT | H2O | LOI | DENS | |

| 1 | 22.92 | 17.62 | 17.1 | 23.1% | 3.0% |

TSFL - Thermal Shock Failure

| CONE | SECS | MODE | MM | |

| 3 | 6 | 4 | fracture | 2.9 |

| 2 | 4.8 | 3 | crack | 3 |

| 1 | 3 | 2 | crack | 3 |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="PV CLAY Feb 2013 Shipment" id="92329" key="gC3SdTqK" date="2021-02-26" codenum="L3664A" location="BOX35" picturebasename=""> <recipelines> <recipeline material="PV Clay" amount="100.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2013-02-27, Modified: 2021-02-26 20:06:31

PV Calc Mix 4

|

Code # L3894D |

Batch # -2 |

| Materials | Amt |

|---|---|

| Silica | 25.000 |

| Nepheline Syenite | 50.000 |

| Tile #6 Kaolin | 20.000 |

| Bentonite | 2.500 |

| Dolomite | 2.500 |

Total:100.00

Auto Unity Formula

|

Si:Al: 5.7:1 6.8 (Molar:6.5) 4.5 |

Notes

Need better plasticity, better maturity. Need to compromise chemistry match to match physical. Switching to NS from custer (for whiteness), more tile6, less silica.

This is about a cone less vitreous than PV clay. But it fires white. Proportions are rounded for production. Plasticity is about the same.

Pictures

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 8 | 95.37 | 90.97 | melting | 8.0 | 4.6% | 4.6% | ||

| 7 | 95.32 | 88.54 | melting | 7.0 | 4.7% | 7.1% | ||

| 6 | 94.45 | 87.48 | 41.48 | 41.74 | 6.0 | 5.6% | 7.4% | 0.6% |

| 5 | 95.27 | 87.11 | 41.68 | 41.81 | 5.0 | 4.7% | 8.6% | 0.3% |

| 4 | 95.28 | 87.6 | 41.92 | 42.93 | 4.0 | 4.7% | 8.1% | 2.4% |

| 3 | 95.4 | 90.86 | 40.88 | 44.75 | 3.0 | 4.6% | 4.8% | 9.5% |

| 2 | 94.88 | 91.63 | 39.73 | 44.78 | 2.0 | 5.1% | 3.4% | 12.7% |

| 1 | 95.05 | 92.37 | 39.42 | 45.08 | 1.0 | 5.0% | 2.8% | 14.4% |

| 9 | 95.49 | 93.25 | 41.69 | 47.82 | -1.0 | 4.5% | 2.3% | 14.7% |

| 10 | 95.81 | 94.1 | 39.71 | 46.22 | -2.0 | 4.2% | 1.8% | 16.4% |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="PV Calc Mix 4" id="192685" key="pBEBYmtG" date="2022-03-09" codenum="L3894D"> <recipelines> <recipeline material="Silica" amount="25.000" tolerance=""/> <recipeline material="Nepheline Syenite" amount="50.000" tolerance=""/> <recipeline material="Tile #6 Kaolin" amount="20.000" tolerance=""/> <recipeline material="Bentonite" amount="2.500" tolerance=""/> <recipeline material="Dolomite" amount="2.500" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2016-08-12, Modified: 2022-03-09 14:45:51