Cordierite Flameware

|

Code # L4696 |

Batch # -2 |

| Materials | Amt |

|---|---|

| *Cordierite Powder | 60.000 |

| Ferro Frit 3249 | 20.000 |

| *6Tile Kaolin | 16.000 |

| VeeGum | 4.000 |

Total:100.00

Notes

A brute force approach to flameware: Use already created cordierite and just bond it together the a low expansion frit.

CaF2 is also a possibility as a flux. The F should gas off and the Ca remain to bond.

Also could glass ceramic frits which devitrify during cooling.

Get cordierite also from reade.com

This has not yet been tested. The amount of clay is minimal, it is really depending on the Veegum for any plasticity. Will be very difficult to mix.

Pictures

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Cordierite Flameware" id="107105" key="yGaSdK9d" date="2024-02-16" codenum="L4696"> <recipelines> <recipeline material="Cordierite Powder" amount="60.000"/> <recipeline material="Ferro Frit 3249" amount="20.000"/> <recipeline material="6Tile Kaolin" amount="16.000"/> <recipeline material="VeeGum" amount="4.000"/> </recipelines> </recipe> </recipes>

Born: 2017-02-20, Modified: 2024-02-16 02:53:28

Cordierite Flameware - more bentonite, added grog

|

Code # L3164A |

Batch # -2 |

| Materials | Amt | |

|---|---|---|

| Tile #6 Kaolin | 68.000 | 59.65% |

| Talc | 32.000 | 28.07% |

| Bentonite | 4.000 | 3.51% |

| *Mulcoa Grog | 10.000 | 8.77% |

Total:114.00

Notes

The intent of this recipe is to see if some cordierite will develop.

Much better plasticity than previous test. No splitting.

One mug lasted 90 seconds without flame cracking.

The TSFL failure was on a mug, with ravenscrag talc glaze. 34 seconds. Very good!

Pictures

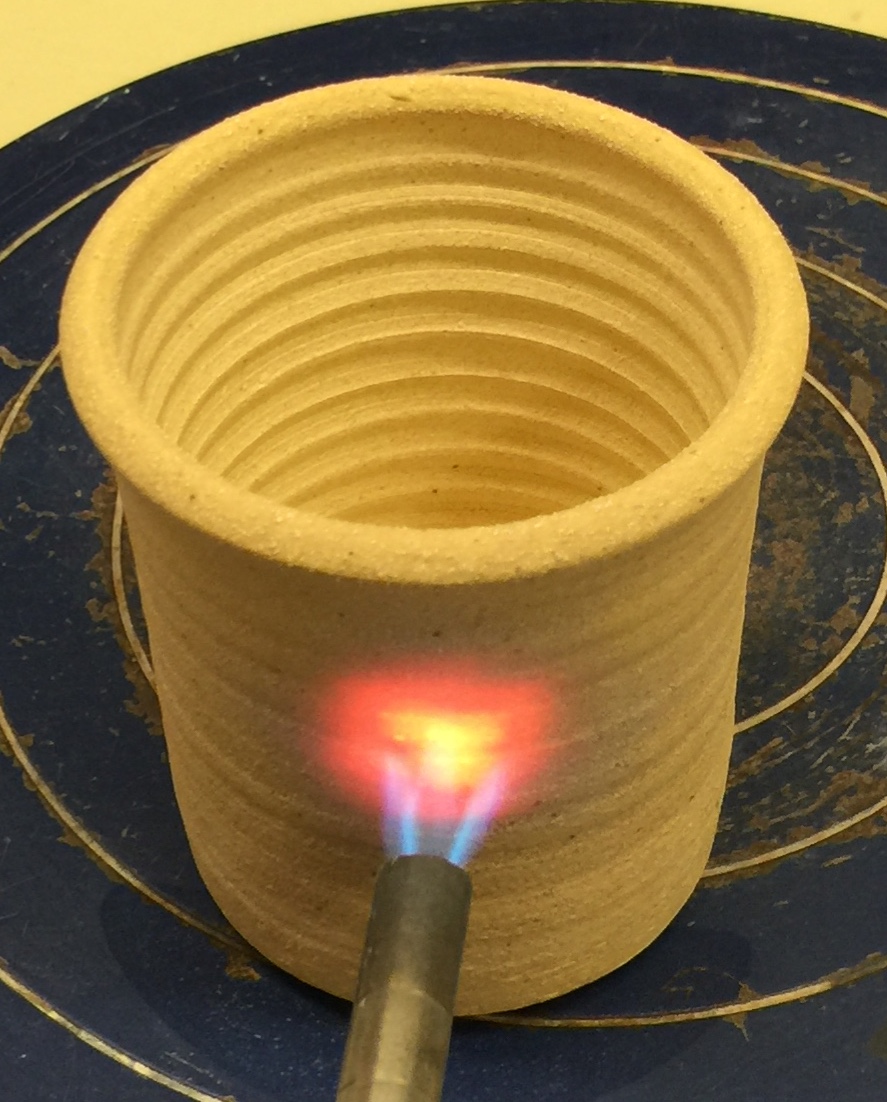

Cordierite L3164A flameware being flame tested

They survived 23, 52 and 90 seconds. The 90 was the best tested of all bodies. It is vitreous enough to fail with an audible crack.

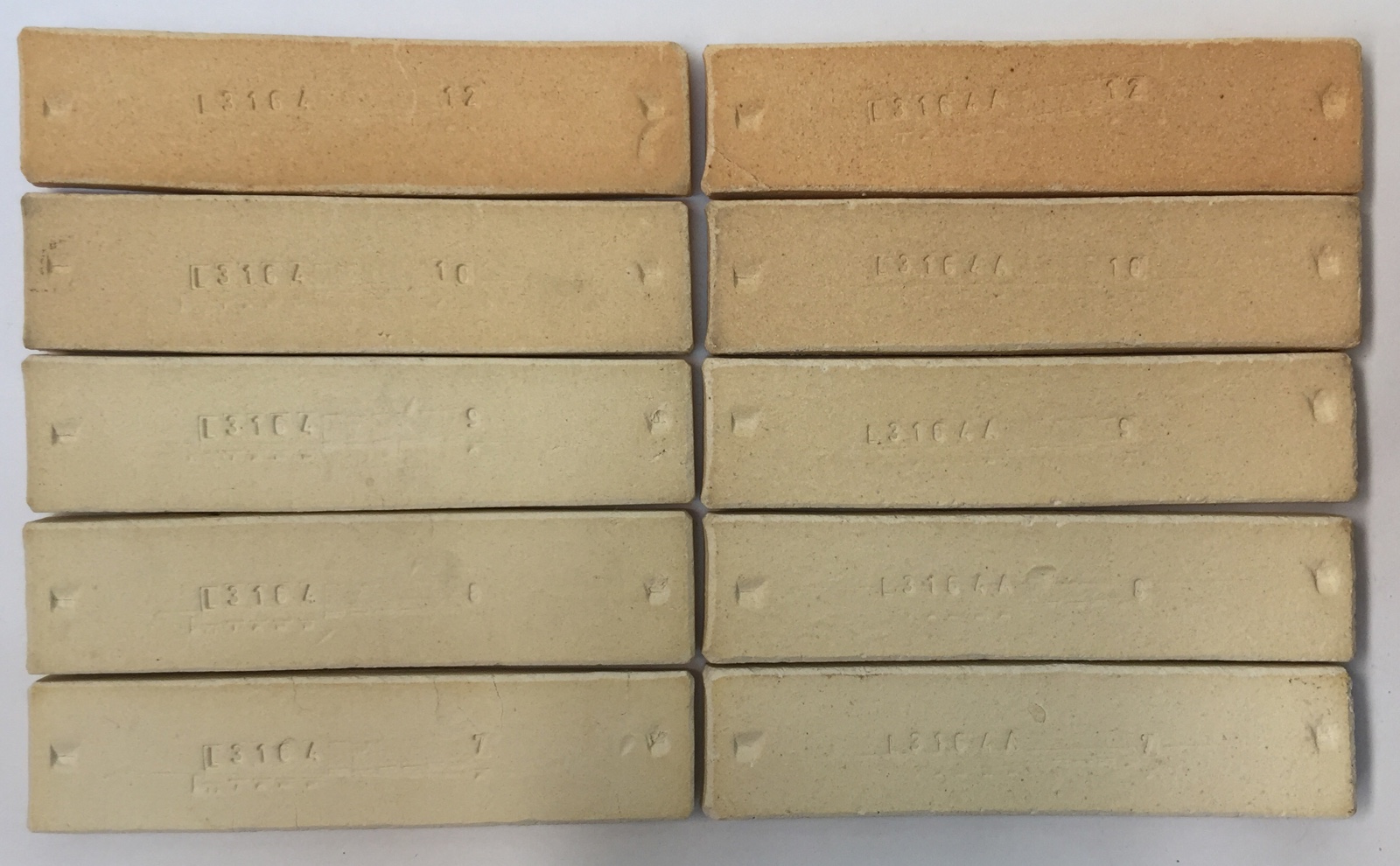

L3164 flameware

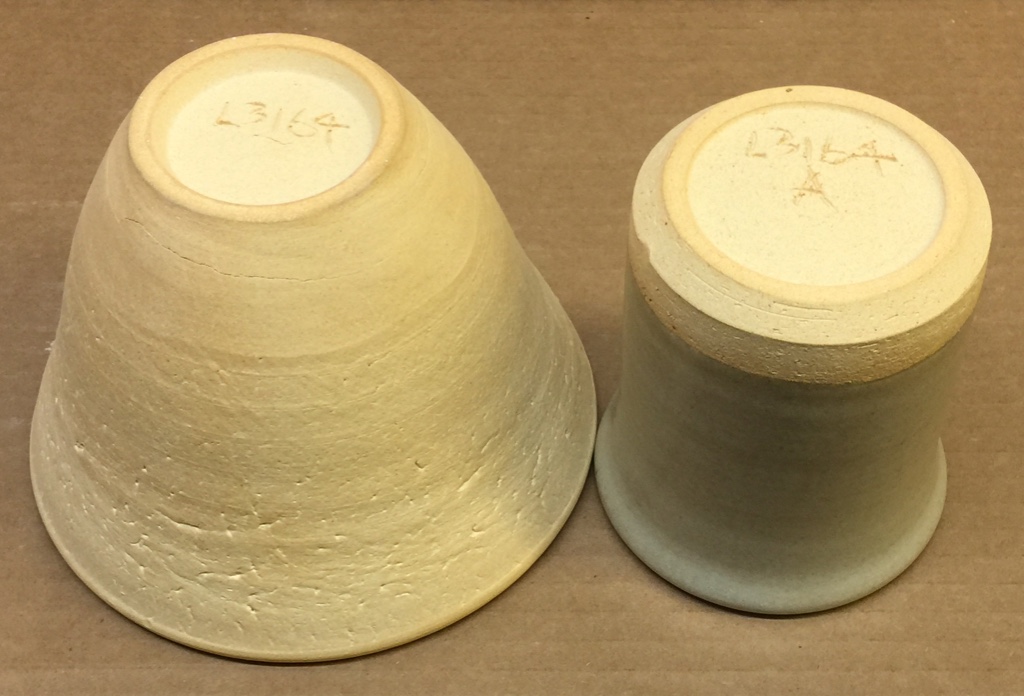

L3164 and L3164A Flameware pieces

Flameware with RavenTalc glaze

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 10 | 93.8 | 88.34 | 34.51 | 37.09 | 10.0 | 6.2% | 5.8% | 7.5% |

| 12 | 93.91 | 88.62 | 33.07 | 35.82 | 10R | 6.1% | 5.6% | 8.3% |

| 9 | 93.71 | 88.27 | 34.12 | 36.84 | 9.0 | 6.3% | 5.8% | 8.0% |

| 8 | 93.58 | 87.85 | 32.49 | 35.11 | 8.0 | 6.4% | 6.1% | 8.1% |

| 7 | 93.45 | 87.48 | 32.63 | 35.57 | 7.0 | 6.6% | 6.4% | 9.0% |

| 6 | 93.62 | 87.5 | 31.31 | 34.93 | 6.0 | 6.4% | 6.5% | 11.6% |

LDW - LOI/Density/Water Content

| WWGT | DWGT | FWGT | H2O | LOI | DENS | |

| 1 | 23.19 | 17.13 | 15.43 | 26.1% | 9.9% |

TSFL - Thermal Shock Failure

| CONE | SECS | MODE | MM | |

| 1 | 10R | 34 | crack | 3mm |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Cordierite Flameware - more bentonite, added grog" id="91174" key="SawdgY5z" date="2024-02-16" codenum="L3164A" picturebasename=""> <recipelines> <recipeline material="Tile #6 Kaolin" amount="68.000" tolerance=""/> <recipeline material="Talc" amount="32.000" tolerance=""/> <recipeline material="Bentonite" amount="4.000" tolerance=""/> <recipeline material="Mulcoa Grog" amount="10.000"/> </recipelines> </recipe> </recipes>

Born: 2000-10-20, Modified: 2024-02-16 02:48:48

Pyrax/Kaolin Flameware

From PMI article Jan 2012

|

Code # L3660G |

Batch # -2 |

| Materials | Amt |

|---|---|

| Pyrax | 60.000 |

| *6Tile Kaolin | 35.000 |

| Bentonite | 5.000 |

Total:100.00

Auto Unity Formula

|

Si:Al: 7.9:1 4.8 (Molar:4.4) 2.4 Cost 0.37 per kg |

Notes

Not plastic, needs way more bentonite.

Very poor performance in TSFL test.

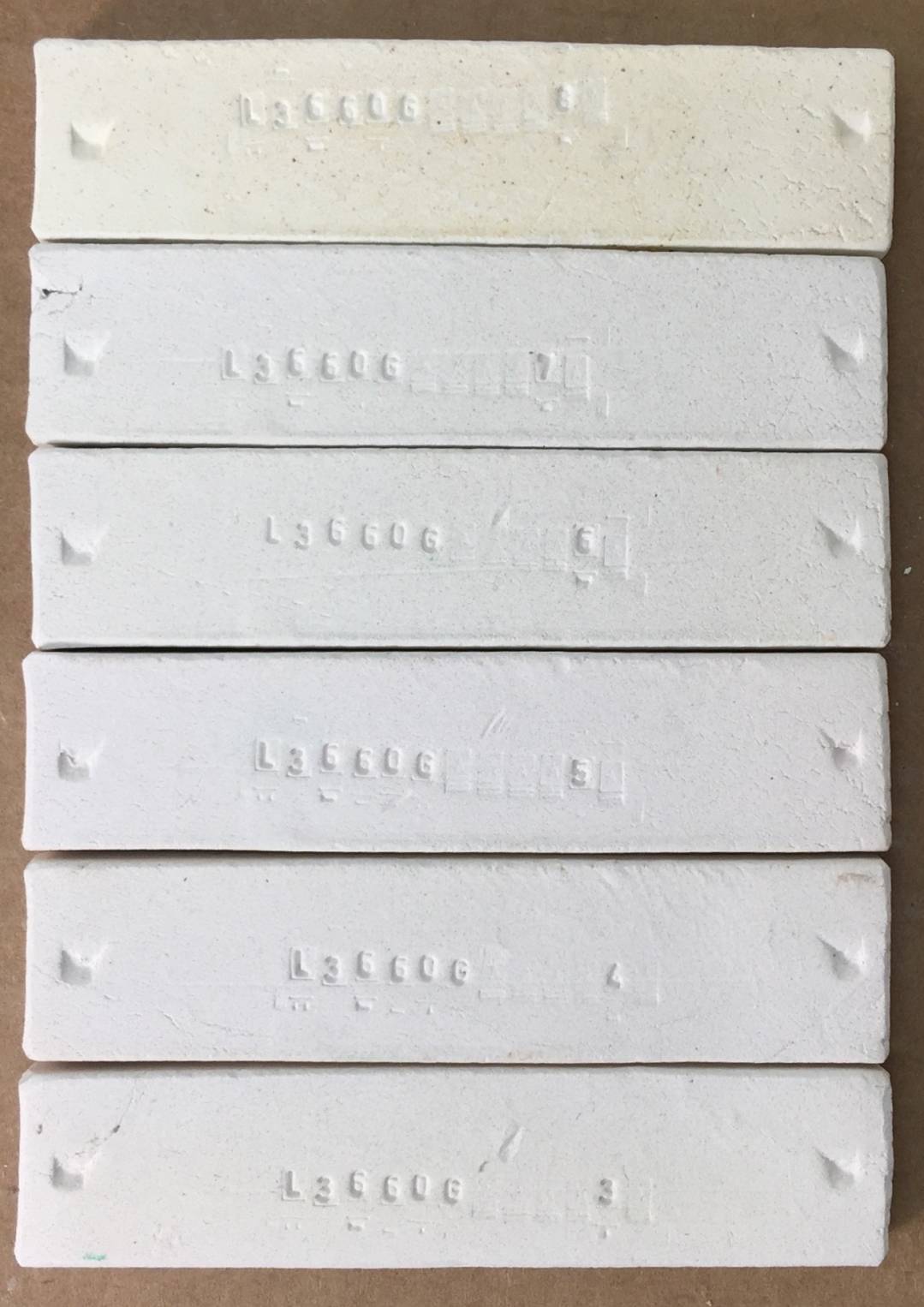

Pictures

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 7 | 94.53 | 92.01 | 30.92 | 35.02 | 10.0 | 5.5% | 2.7% | 13.3% |

| 8 | 94.38 | 91.58 | 31.54 | 35.66 | 10R | 5.6% | 3.0% | 13.1% |

| 6 | 94.47 | 91.97 | 31.78 | 36.05 | 8.9 | 5.5% | 2.6% | 13.4% |

| 5 | 94.35 | 92.4 | 32.93 | 37.77 | 5.9 | 5.7% | 2.1% | 14.7% |

| 3 | 94.49 | 92.14 | 32.79 | 37.43 | 5.5% | 2.5% | 14.2% | |

| 4 | 94.55 | 92.27 | 33.95 | 38.81 | 5.5% | 2.4% | 14.3% |

LDW - LOI/Density/Water Content

| WWGT | DWGT | FWGT | H2O | LOI | DENS | |

| 1 | 19.83 | 14.57 | 13.56 | 26.5% | 6.9% |

TSFL - Thermal Shock Failure

| CONE | SECS | MODE | MM | |

| 6 | 9 | 3 | fracture | 3 |

| 4 | 7 | 4 | fracture | 2.9 |

| 5 | 6 | 3 | crack | 4.2 |

| 1 | 5 | 8 | Crack | 2.8 |

| 2 | 5 | 7 | Crack | 4.5 |

| 3 | 4.8 | 9 | fracture | 3.2 |

| 7 | 1 | 2 | crack | 3 |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Pyrax/Kaolin Flameware" keywords="From PMI article Jan 2012" id="74338" key="wtTvJrdw" date="2024-02-16" codenum="L3660G"> <recipelines> <recipeline material="Pyrax" amount="60.000" tolerance=""/> <recipeline material="6Tile Kaolin" amount="35.000" tolerance=""/> <recipeline material="Bentonite" amount="5.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2015-04-28, Modified: 2024-02-16 02:54:51

Flameware body from French mfgr

|

Code # L4697 |

Batch # -2 |

| Materials | Amt | |

|---|---|---|

| Silverline 303 Talc | 26.000 | 24.76% |

| Kyanite | 29.000 | 27.62% |

| Ferro Frit 3110 | 10.000 | 9.52% |

| Tile #6 Kaolin | 36.000 | 34.29% |

| Bentonite | 4.000 | 3.81% |

Total:105.00

|

Si:Al: 2.7:1 5.3 (Molar:4.9) 6.2 |

Notes

Their chemistry of the body is: SiO2 - 50% Al2O3 - 32 % Fe2O3 - 0,7% TiO2 - 0.6% CaO - 0.1% MgO - 8% Na2O - 0.3% K2O - 1.6% PF - 5.6%

This is an effort to extrapolate the materials in the recipe from that chemistry. It seems likely that cordierite and kaolin would be the main ingredients. But failing the ability to fire to cordierite temperatures this appears to be the only way to match this chemistry.

Pictures

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Flameware body from French mfgr" id="242336" key="tLi2L1Wv" date="2024-02-16" codenum="L4697"> <recipelines> <recipeline material="Silverline 303 Talc" amount="26.000" tolerance=""/> <recipeline material="Kyanite" amount="29.000" tolerance=""/> <recipeline material="Ferro Frit 3110" amount="10.000" tolerance=""/> <recipeline material="Tile #6 Kaolin" amount="36.000" tolerance=""/> <recipeline material="Bentonite" amount="4.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2023-07-27, Modified: 2024-02-16 03:25:24

Pyrax Flameware (low fire)

From PMI article Jan 2012

|

Code # L3660P |

Batch # -2 |

| Materials | Amt |

|---|---|

| Pyrax | 50.000 |

| *6Tile Kaolin | 20.000 |

| Bentonite | 10.000 |

| Ferro Frit 3249 | 10.000 |

| Kyanite | 10.000 |

Total:100.00

Notes

G needed way more bentonite.

Use the low expansion frit to bond particles.

Pictures

URLs

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 7 | 93.88 | 90.96 | 33.98 | 37.04 | 7.0 | 6.1% | 3.1% | 9.0% |

| 6 | 93.86 | 90.97 | 34.19 | 36.42 | 5.7 | 6.1% | 3.1% | 6.5% |

| 5 | 93.78 | 91.36 | 35.39 | 38.02 | 5.0 | 6.2% | 2.6% | 7.4% |

| 4 | 93.87 | 91.58 | 35.26 | 37.93 | 4.0 | 6.1% | 2.4% | 7.6% |

| 1 | 94.17 | 92.75 | 34.40 | 35.94 | 02.4 | 5.8% | 1.5% | 4.5% |

| 2 | 94.04 | 92.07 | 34.11 | 37.17 | 2.0 | 6.0% | 2.1% | 9.0% |

| 3 | 93.81 | 92.55 | 34.16 | 39.15 | -4.0 | 6.2% | 1.3% | 14.6% |

TSFL - Thermal Shock Failure

| CONE | SECS | MODE | MM | CM | |

| 1 | 4 | 13 | hairline | 8 | 5.7 |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Pyrax Flameware (low fire)" keywords="From PMI article Jan 2012" id="247642" key="PSydbXvN" date="2024-01-09" codenum="L3660P"> <recipelines> <recipeline material="Pyrax" amount="50.000" tolerance=""/> <recipeline material="6Tile Kaolin" amount="20.000" tolerance=""/> <recipeline material="Bentonite" amount="10.000" tolerance=""/> <recipeline material="Ferro Frit 3249" amount="10.000" tolerance=""/> <recipeline material="Kyanite" amount="10.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2015-04-28, Modified: 2024-01-09 20:25:44

Lithium Flameware Test

|

Code # L4458 |

Batch # -2 |

| Materials | Amt |

|---|---|

| OM-4 Ball Clay | 50.000 |

| Lithium Carbonate | 1.800 |

| Petalite | 38.200 |

| Minspar 200 | 10.000 |

Total:100.00

Notes

Original recipe had 30 Hawthorne Fireclay, 20 OM4, switched that for 50 ball clay (assuming the fireclay is just a coarse particled ball clay).

Not tested.

Pictures

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Lithium Flameware Test" id="202524" key="EMFY7DE8" date="2024-02-16" codenum="L4458"> <recipelines> <recipeline material="OM-4 Ball Clay" amount="50.000" tolerance=""/> <recipeline material="Lithium Carbonate" amount="1.800" tolerance=""/> <recipeline material="Petalite" amount="38.200" tolerance=""/> <recipeline material="Minspar 200" amount="10.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2021-08-09, Modified: 2024-02-16 03:28:34

Flameware - Very High Pyrax with Molochite

|

Code # L3660C |

Location BOX54 |

Batch # -2 |

| Materials | Amt |

|---|---|

| Bentonite | 5.000 |

| Pyrax 8F (Pyrax Pyrophyllite) | 60.000 |

| Pioneer Kaolin | 20.000 |

| Molochite 50/80 (Molochite) | 15.000 |

Total:100.00

Notes

The objectives are:

-Produce the lowest possible thermal expansion in a sintered (not vitrified) body. That means the highest possible percentage low expansion Pyrax with some low expansion grog (to terminate any microcracks that might appear as a result of sudden heating/cooling). Pyrax hosts plasticity well, this will minimize the percentage of clay needed to make the body workable.

-Use an absolute minimum of quartz-containing clay materials, that means no ball clay or fireclay (only kaolin and bentonite).

-Fire as high as possible (to get fired strength) but not so high that any vitrification process starts and alters the mineral structure of the pyrax thereby compromising its low expansion. Flame-shock tests on tiles fired at a range of temperatures should demonstrate this.

Make shrinkage/porosity/water content test specimens as well as tiles and a wheel thrown piece.

On the wheel plasticity is low, it is barely throwable without splitting at the lip, 1% more bentonite is needed. It does roll well for making tiles, but is somewhat sticky. Dry strength is better than expected.

At cone 6, this is very porous, this is going to need a much high temperature to develop any sort of maturity.

Pictures

Pyrax flame ware body test

Tiles will be used for flame shock testing. The bars are for drying shrinkage and fire shrinkage and porosity at 5 temperatures. The small sample is for water content and LOI measurements. The small throw piece was done to evaluate the plasticity.

Flameware L3660C crazing

Bisque fired at cone 8, then glaze fired at cone 6 using M370 clear (G2926B).

L3360C, D flameware bars - Pyrax, Molochite

URLs

A revised mix to increase plasticity

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 5 | 94.29 | 90.42 | 35.78 | 39.42 | 10.0 | 5.7% | 4.1% | 10.2% |

| 9 | 94.14 | 90.73 | 35.69 | 39.95 | 9.0 | 5.9% | 3.6% | 11.9% |

| 8 | 94.07 | 91.16 | 35.89 | 40.48 | 8.0 | 5.9% | 3.1% | 12.8% |

| 7 | 93.94 | 91.65 | 35.42 | 40.21 | 6.8 | 6.1% | 2.4% | 13.5% |

| 6 | 94.15 | 91.83 | 36.43 | 41.58 | 6.0 | 5.8% | 2.5% | 14.1% |

LDW - LOI/Density/Water Content

| WWGT | DWGT | FWGT | H2O | LOI | DENS | |

| 1 | 21.88 | 16.88 | 16.15 | 22.9% | 4.3% |

TSFL - Thermal Shock Failure

| CONE | SECS | MODE | MM | |

| 1 | 7 | 25 | Ping | 4.6 |

| 2 | 5 | 7 | Ping | 4.8 |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Flameware - Very High Pyrax with Molochite" id="73945" key="s7XNLWeH" date="2016-10-25" codenum="L3660C" location="BOX54" picturebasename=""> <recipelines> <recipeline material="Bentonite" amount="5.000" tolerance=""/> <recipeline material="Pyrax 8F" lookup="Pyrax Pyrophyllite" amount="60.000" tolerance=""/> <recipeline material="Pioneer Kaolin" amount="20.000" tolerance=""/> <recipeline material="Molochite 50/80" lookup="Molochite" amount="15.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2012-11-28, Modified: 2016-10-25 16:43:48