Project Name

Seed Pelleting Clay

Project Codenumber

UnAssigned

Notes

As I add trial recipes, they columns will grow rightward on this page.

Processors are said to use diatomaceous earth, limestone, gypsum, bentonite, vermiculite, talc, zeolite, silica, pumice and calcium carbonate. For safety reasons (harmful dust) I would avoid silica, talc, pumice and especially diatomaceous earth (vermiculite is not a powder). Gypsum, as a hardener, would mean more complexity in manufacture (because it sets-to-harden), better to use a gum (glue, binder) that dries-to-harden. Zeolite is expensive, but it would hold water, perhaps it could be part of a recipe. Bentonite would really help in water retention and hardening, but it has high shrinkage so only a small percentage can be used.

Properties needed are a material that will stick together nicely, without flaking, and absorb moisture nicely to allow the seed to germinate better. Clays are ideal for this because they have all three properties. Clay particles are tiny water magnets, that is why they are plastic when wet. Clays can also be very sticky, or stickiness can be enhanced by added bentonite. And clays harden when they dry.

My common-sense recipe would contain mostly kaolin (pure mineral clay, it is cheap and easy to get, we stock thousands of bags of many brand names), bentonite, calcium carbonate (as a filler) and powdered CMC gum. However, since kaolin is such a fluffy powder (because it is ground to a very fine particle size), very high energy powder-mixing is required to blend it with the gum and filler.

A second, perhaps more practical option, is to use a natural, silty clay that we mine, it is called 3D. It would be much easier to mix (its particle size is larger than kaolin, we only hammer-mill it). I can add bentonite as needed to enhance its stickiness.

We stock dozens of ceramic minerals and clays, we have all of the above mentioned materials. Plus much more.

The equipment makers call this "pelletizing/tumble-growth agglomeration".

Seed pelleting clay and binder

|

Code # L4421 |

Batch # -2 |

Notes

Processors are said to use diatomaceous earth, limestone, gypsum, bentonite, vermiculite, talc, zeolite, silica, pumice and calcium carbonate. For safety reasons (harmful dust) I would avoid silica, diatomaceos earth, talc, pumice and vermiculite (and the latter is not a powder). Gypsum, as a hardener, would mean more complexity in manufacture (because it sets), better to use a gum (glue, binder). Zeolite is expensive, but it would hold water, perhaps it could be part of a recipe. Bentonite would really help in water retention and hardening, but it has high shrinkage so only a small percentage can be used.

Properties needed are a material that will stick together nicely, without flaking, and absorb moisture nicely to allow the seed to germinate better.

My common-sense recipe would contain kaolin (cheap and abundant), bentonite, calcium carbonate and powdered CMC gum. However, since kaolin is such a fluffy powder

We have all of the above materials, they are common in ceramics.

The equipment makers call this "pelletizing/tumble-growth agglomeration".

I dried, weighed, fired, weighed again to calculate an LOI of 38% (at 1850F). This suggests a high percentage of calcium carbonate (it has an LOI of 40-45%). However the sample does not hydrate in water, so it is not calcium carbonate. Diatomaceous earth has an LOI of 6-8%. The LOI of this disqualifies it as pumice also (although the yellowish color is similar).

Pictures

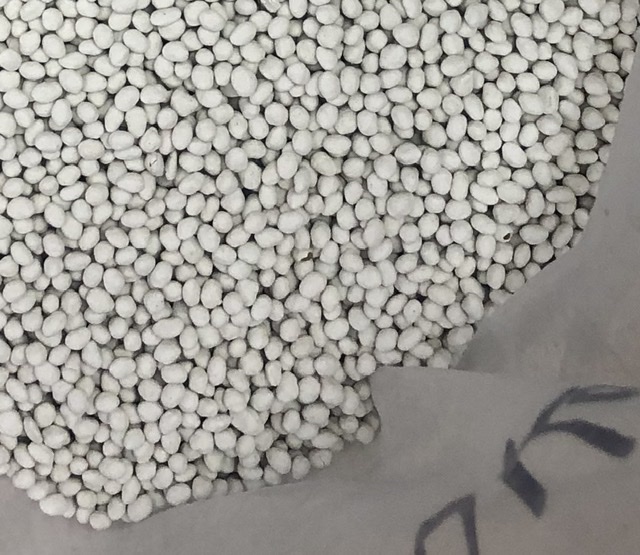

The seeds

These generate considerable dust on handling! It is important to know what the dust is. If it were diatomaceous earth, there is considerable potential lung hazard.

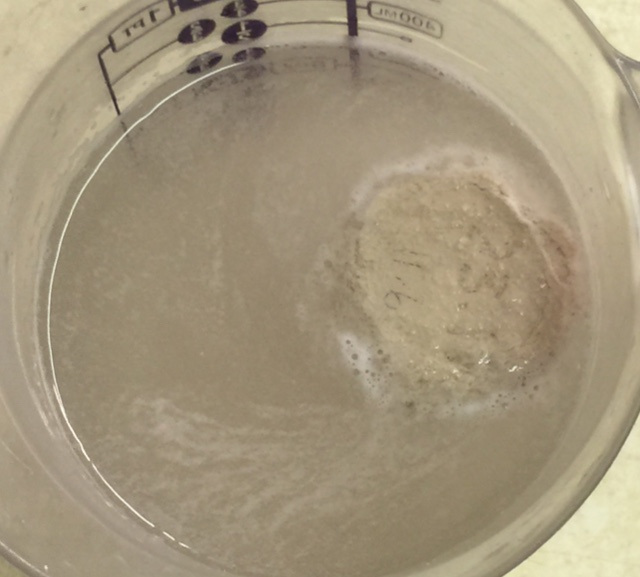

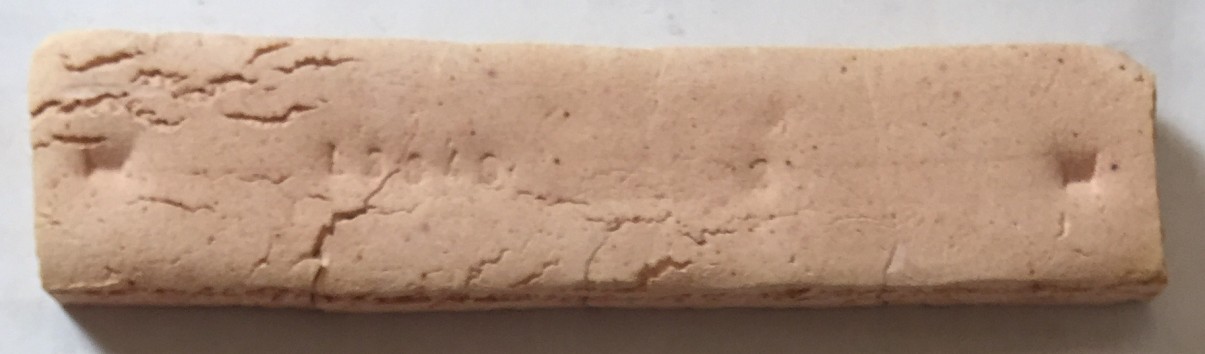

Clay material washed off seeds

In boiling water the coating readily washed off. The binder prevented complete slaking, but with soaking it de-agglomerated and went through a 30 mesh sieve to remove all remaining seeds.

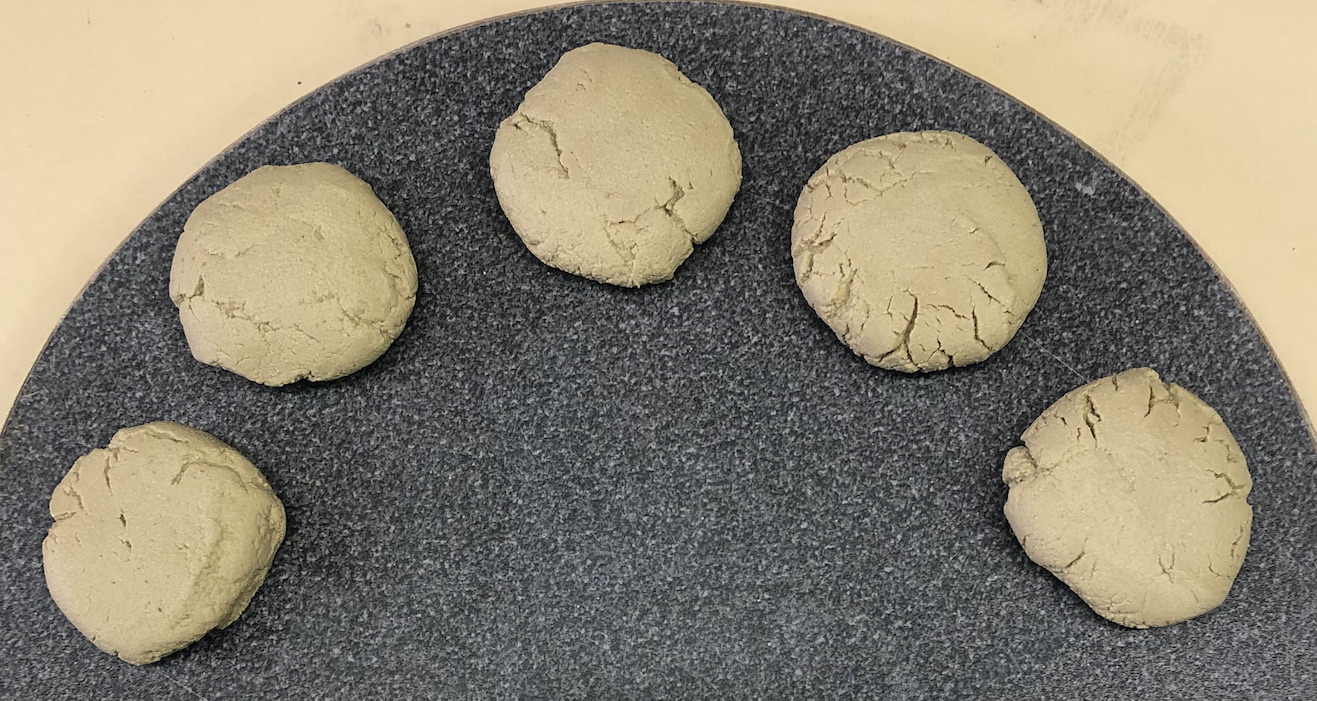

Forming properties are very poor. The material either contains minimal clay, the clay being used has very low plasticity or the binder is affecting plasticity.

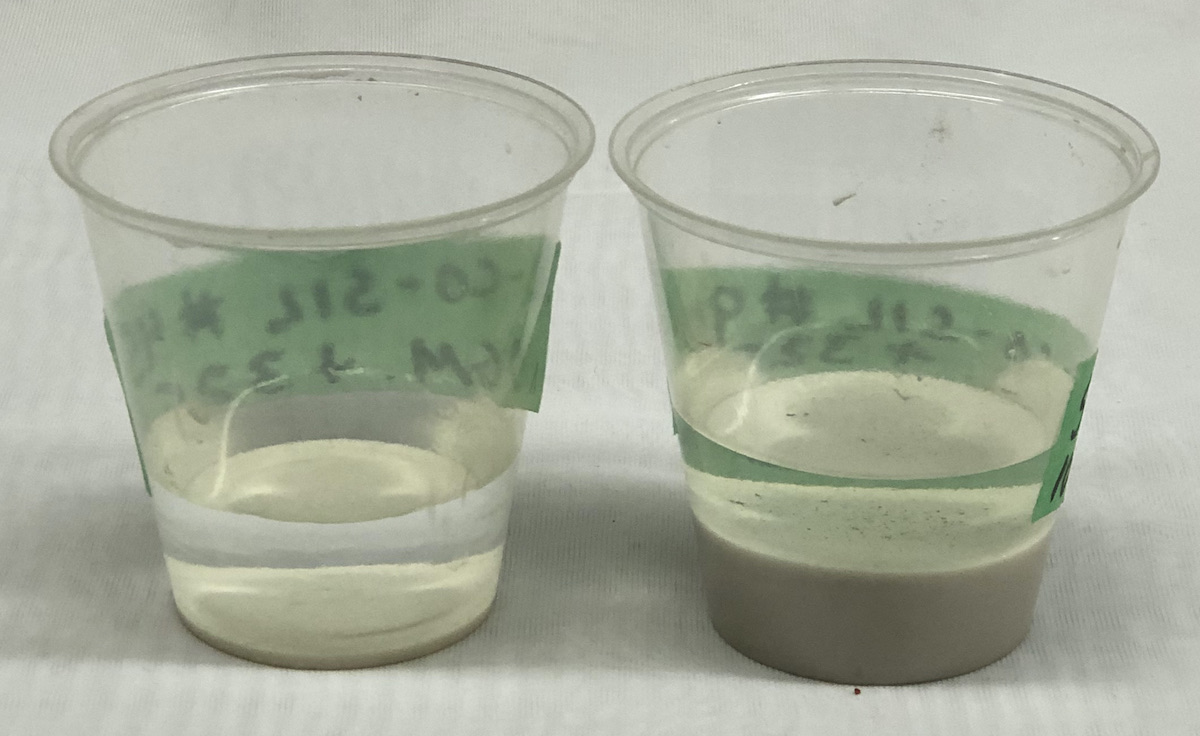

Reaction to vinegar

Calcium carbonate, on the right, fizzes actively. The seed pellets on the left and doing so mildly. This means that calcium carbonate makes up only a part of their recipe. Given the wetted color this appears to be kaolin-based. Some kaolins are markedly stickier than others. They would need to be mixed with a filler to reduce drying shrinkage, so the filler is likely dolomite or calcium carbonate.

Seeds fired to 1850F

The seeds were all completely burned away. The heat has removed the plasticity of the material. The powder is not reacting to vinegar, indicating little or no calcium carbonate.

100 grams +325 mesh

URLs

Testdata

LDW - LOI/Density/Water Content

| DWGT | FWGT | H2O | LOI | DENS | |

| 1 | 11.81 | 7.33 | 37.9% | ||

| 2 | 9.13 | 5.56 | 39.1% | ||

| 3 | 10.84 | 6.56 | 39.5% |

XML (to paste into Insight)

Born: 2021-03-24, Modified: 2021-03-31 12:15:21

Diatomaceous Earth (Ant Killer)

|

Code # L3840 |

Batch # -2 |

Notes

I bought this at Home Depot in Dec 2015. It is ant killer. The label calls it diatomaceous earth claims the material is 90% silica (which is what diatomaceous earth is). However if contains additives (poison and yeast with I could smell when it was wet). It cost more than $10 for 200 grams of material.

It is barely plastic enough to make test bars, feels similar to L3709A.

This fires very clean and white so it is very pure. The manufacturers are obviously screened it well to remove impurities. It likely did not require much grinding.

Warnings on the container and articles on the internet confirm that this material is very hazardous to breathe. This is because the silica particles are angular and extremely small (can become airborne and get stuck in the lungs very easily).

Pictures

Diatomaceous earth product

Dry diatomaceous earth floats in water!

Commercial product vs. Edmonton raw material

Obviously the Edmonton material will need processing to clean it up to match the commercial one. However simply screening out the particulates (which are not significant) would transform it. However there also appear to be soluble salts so I might need to be washed also (depending on the application).

L3840 Diatomaceous Earth (Ant Killer) fired bars

This has extremely low plasticity.

URLs

Example Diatomaceous data sheet

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 1 | 97.47 | 90.97 | 15.02 | 23.9 | 10.0 | 2.5% | 6.7% | 59.1% |

| 2 | 97.51 | 90.44 | 15.72 | 27.52 | 10R | 2.5% | 7.3% | 75.1% |

LDW - LOI/Density/Water Content

| WWGT | DWGT | H2O | LOI | DENS | |

| 1 | 23.17 | 11.66 | 49.7% |

XML (to paste into Insight)

Born: 2015-12-11, Modified: 2021-03-31 12:10:04

3D 100 mesh

|

Code # L4249B |

Batch # -2 |

Notes

3D is a silty, fine grained natural mix of clay, silt, feldspar and quartz. 3D is unlike most of our other clays, they are very plastic and sticky, for use in pottery, and thus have higher drying shrinkages. 3D can be conditioned by additions to adjust its properties. It is easy to process and we have unlimited reserves.

Yield on lab screening of 42 mesh material:

110g +100 mesh

1350g -100 mesh

Wet sieved to 100 mesh again.

+100: 73g

-100: 1355

Pictures

URLs

XML (to paste into Insight)

Born: 2021-02-06, Modified: 2022-01-31 11:14:18