Catchment Clay Yukon

|

Code # L4287A |

Batch # -2 |

Notes

Slaked clay was sieved at 30 mesh. The material is less plastic than Midfield, but that is likely because the latter was screen to 80 mesh, removed much more of the non-plastic particulates. However this has a higher drying shrinkage, that is strange.

Pictures

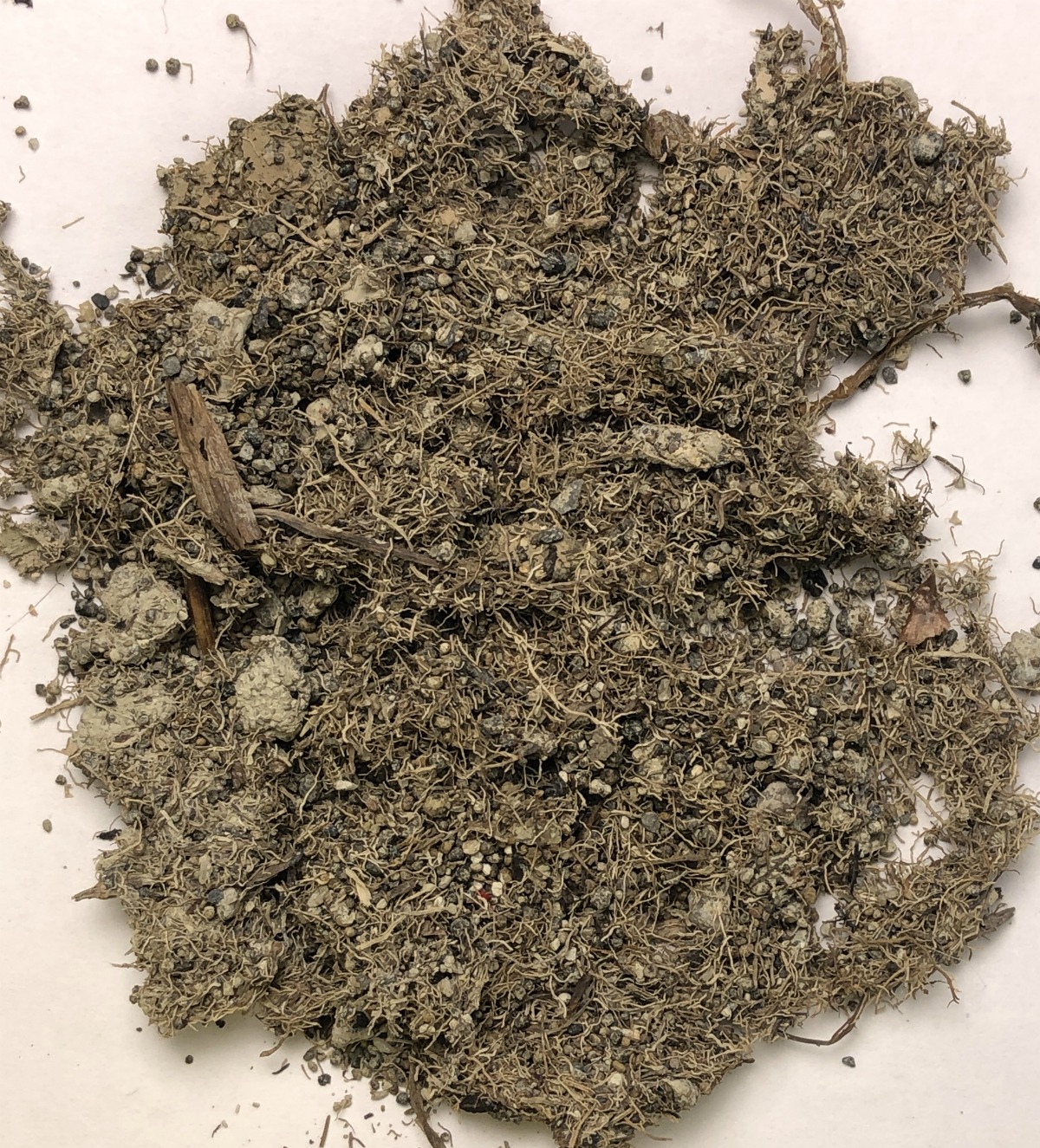

+30 mesh Yukon Catchment clay

Much more oversize material than the Midfield and the gravel is larger. That being said, this could still be utilized, it would just mean a lower yield from 80 mesh.

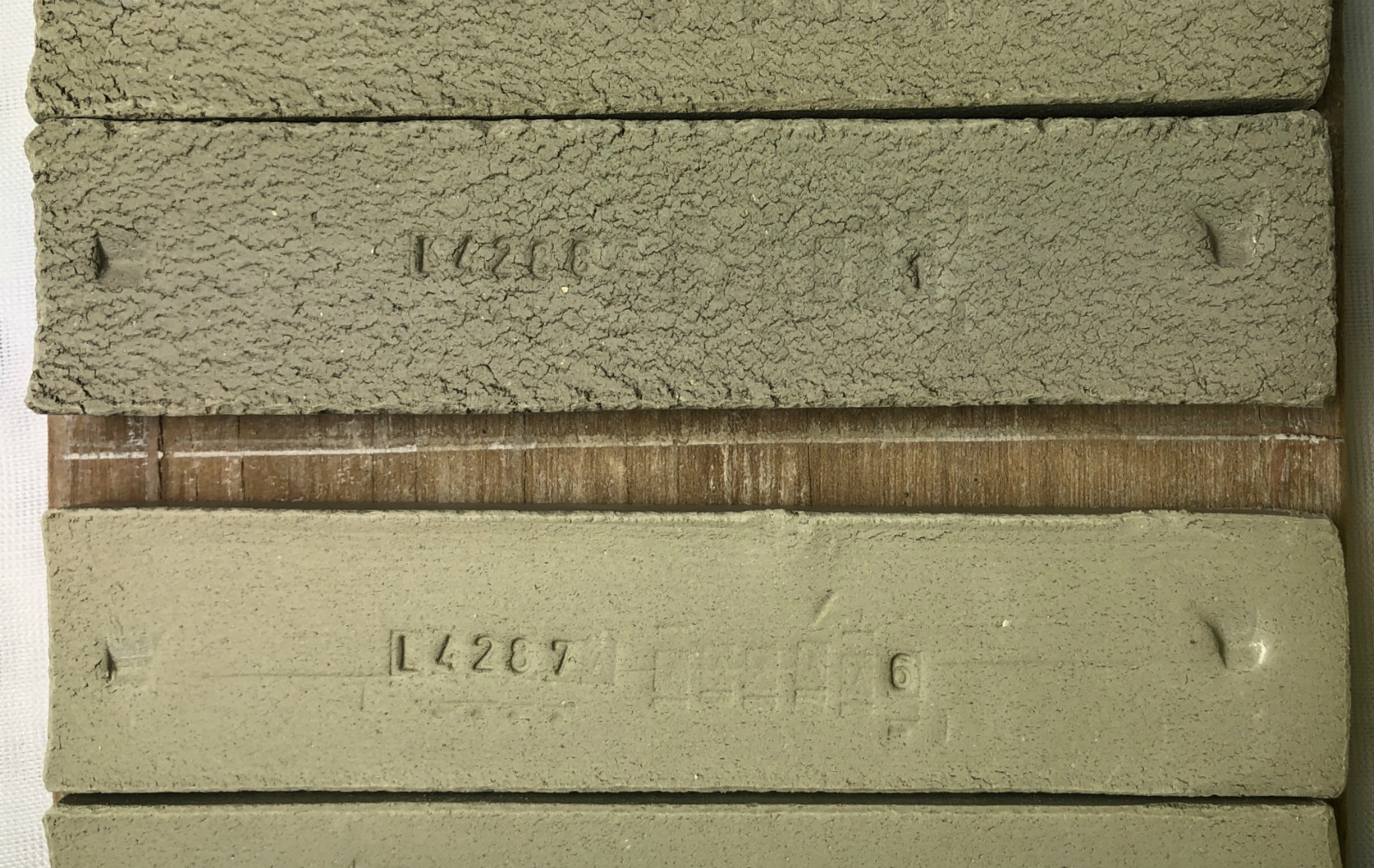

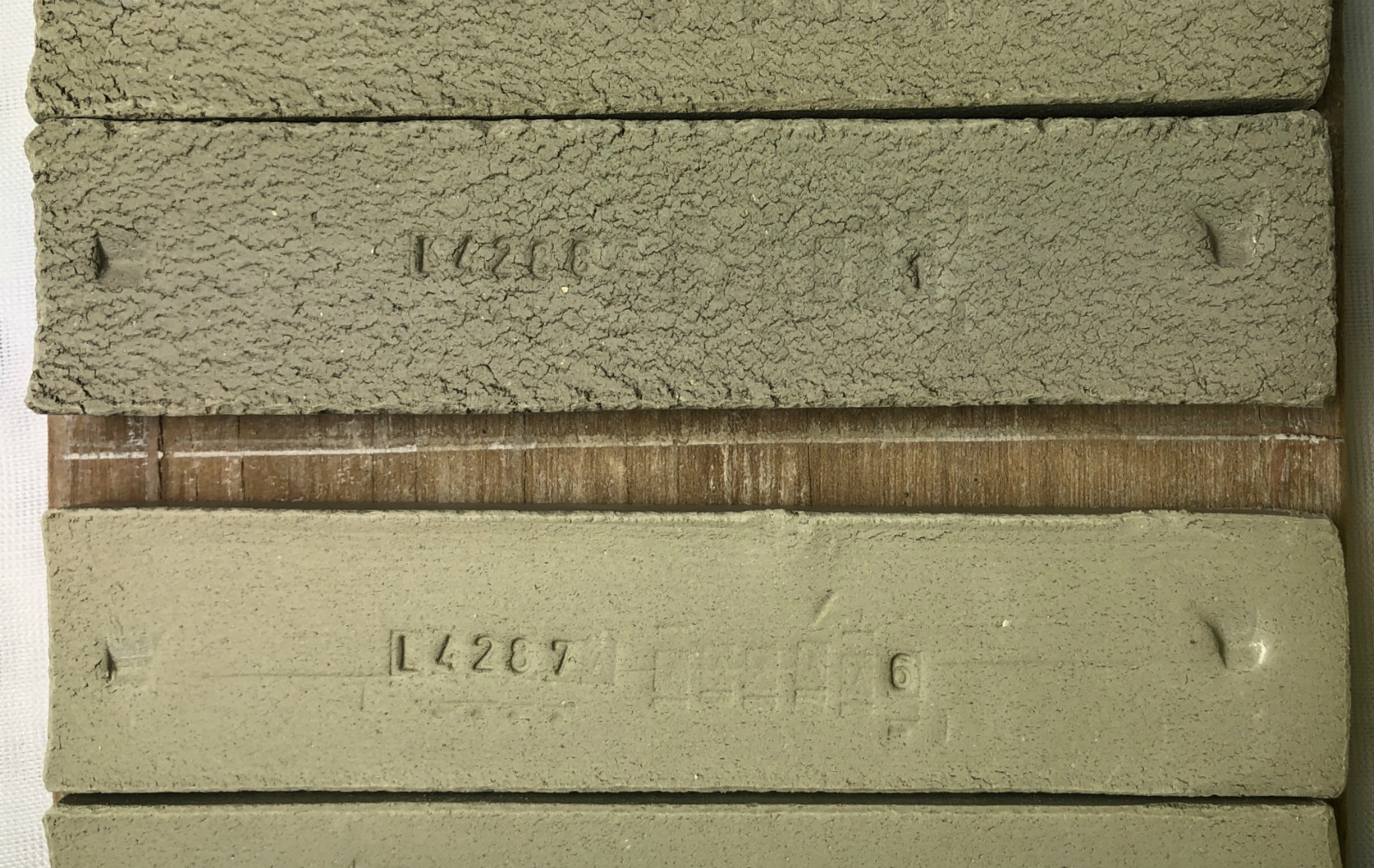

Dried test bars - Yukon clays

Catchment (top) has only had +30 mesh material removed (over which there was alot more). The Midfield is minus 80 mesh.

The drying shrinkage of these materials is typical of a normal pottery clay. And plasticity is good. That means it might be feasible to use these as is for potter. Later I will test their reaction to glaze at cone 1 (I have a good cone 1 glaze I am working on).

L4287, L4287A Yukon clay bars

Right: Midfield at cone 4, 3, 2, 1, 01

Left: Catchment

The cone 4 bars are not bloating or melting, but the fired shrinkage is high. At cone 3 there is a dramatic difference. So the firing temp for vitreous ware could be 3.5?? But cone 2 will be much better to avoid warping (It will still be strong, although having significant porosity).

The soluble salts appear to be low.

Fire cone 03 with G1916Q glaze

The has 2% added iron oxide to fine the bubbles but it did not work here. It also ran much more more on this piece than others in the kiln, likely because of its extra porosity the glaze when on thicker.

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | TEMP | DSHR | FSHR | ABS | |

| 7 | 93.25 | 88.5 | 43.1 | 5.0 | 6.8% | 5.1% | |||

| 1 | 93.53 | 85.08 | 36.3 | 36.35 | 4.2 | 6.5% | 9.0% | 0.1% | |

| 8 | 93.31 | 87.43 | 35.23 | 39.49 | 3.0 | #4 | 6.7% | 6.3% | 12.1% |

| 9 | 93.45 | 87.60 | 35.48 | 38.33 | 2.0 | 6.6% | 6.3% | 8.0% | |

| 6 | 93.18 | 88.37 | 31.49 | 1.0 | 6.8% | 5.2% | |||

| 2 | 93.53 | 86.21 | 38.1 | 6.5% | 7.8% | ||||

| 5 | 93.25 | 90.47 | 35.51 | 41.3 | -1.0 | 6.8% | 3.0% | 16.3% | |

| 3 | 93.45 | 91.84 | 35.56 | 42.35 | -2.0 | 6.6% | 1.7% | 19.1% | |

| 4 | 93.31 | 92.13 | 35.3 | 42.35 | -3.0 | 6.7% | 1.3% | 20.0% |

XML (to paste into Insight)

Born: 2020-07-03, Modified: 2020-10-02 21:28:11

Midfield Clay Yukon

|

Code # L4287 |

Batch # -2 |

Notes

Clay slaked quickly to produce a smooth slurry.

Sieved out +30 mesh particles first, then +80.

About 2% is plus 80 mesh.

It was quick to sieve at 80 mesh (provided the slurry is thin enough).

It dewatered quickly on the plaster table so natural bentonite content appears low.

The clay feels fairly plastic on handling, and is sticky and low in soluble salts.

It has a low drying shrinkage. Wheelthrowing and handbuilding trials show it is not plastic enough. That means it will need an addition of bentonite.

The porosity is high all the way to cone 1, but it is melting by cone 4. Likely around cone 2 it will reach a compromise between density and resistance to warping during firing. It will be tricky to fire, requiring good control of temperature. Ware will need to be thin walled for good heat penetration. Firings will need to have a hold period at the end. This will thus be tricky to fire in a primitive kiln. Unless, of course, high density is not needed.

Pictures

+30 mesh Yukon Midfield

A fair amount of plant material. This needs to be removed to reduce carbon burnout.

Some fine gravel also.

30-80 mesh Yukon Midfield clay

Still a fair amount of plant material. And more fine gravel.

Dried test bars - Yukon clays

Catchment (top) has only had +30 mesh material removed (over which there was alot more). The Midfield is minus 80 mesh.

The drying shrinkage of these materials is typical of a normal pottery clay. And plasticity is good. That means it might be feasible to use these as is for potter. Later I will test their reaction to glaze at cone 1 (I have a good cone 1 glaze I am working on).

L4287, L4287A Yukon clay bars

Right: Midfield at cone 4, 3, 2, 1, 01

Left: Catchment

The cone 4 bars are not bloating or melting, but the fired shrinkage is high. At cone 3 there is a dramatic difference. So the firing temp for vitreous ware could be 3.5?? But cone 2 will be much better to avoid warping (It will still be strong, although having significant porosity).

The soluble salts appear to be low.

L4287 thrown cup

Not plastic enough. You can see some vertical splitting near the rim because of this.

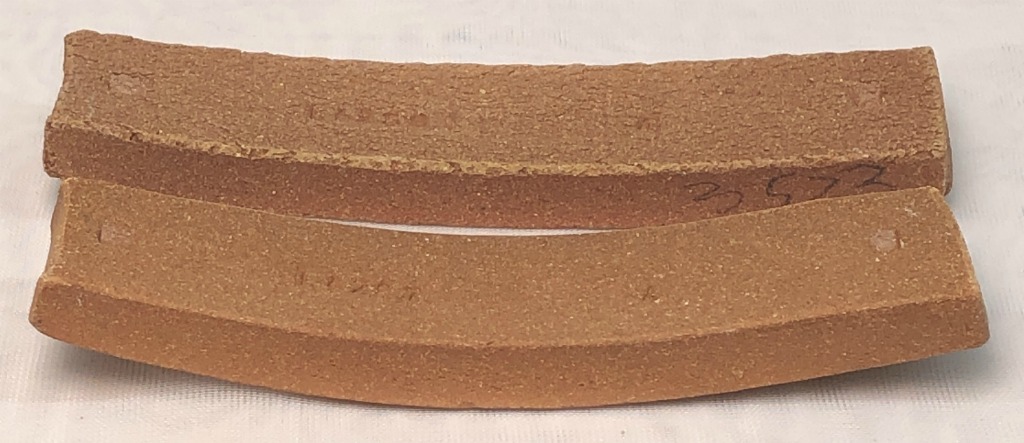

Cone 3 - bars curled

Despite 108F/hr rate of rise. These are curling because the upper surface of the far was hotter and thus shrinking more that the lower surface.

A slow approach to final temp would be needed for ware not to warp at cone 3.

Or: Note the read bar, which has the 30-80 mesh aggregate is warping less. That means that an addition of silica sand (and bentonite since it needs plasticity) to the 80 mesh material might help.

Added 10% F-75 silica sand, 3% bentonite

L4287B

This improves the throwing very much!

The silica sand should help prevent warping during firing.

L4254B fired bars

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | TEMP | DSHR | FSHR | ABS | |

| 1 | 94.16 | 82.75 | 34.43 | 34.44 | 4.2 | 5.8% | 12.1% | 0.0% | |

| 7 | 94.06 | curled | 33.43 | 36.5 | 3.0 | #4 | 5.9% | 9.2% | |

| 2 | 94.22 | curled | 35.94 | 38.3 | 2.0 | 5.8% | 6.6% | ||

| 8 | 93.97 | 84.73 | 34.86 | 37.26 | 2.0 | 6.0% | 9.8% | 6.9% | |

| 6 | 93.8 | 86.71 | 31.49 | 34.95 | 1.0 | 6.2% | 7.6% | 11.0% | |

| 5 | 94.1 | 89.89 | 33.36 | 39.97 | -1.0 | 5.9% | 4.5% | 19.8% | |

| 3 | 93.97 | 91.64 | 34.92 | 43.48 | -2.0 | 6.0% | 2.5% | 24.5% | |

| 4 | 94.06 | 92.17 | 33.48 | 42.22 | -3.0 | 5.9% | 2.0% | 26.1% |

SIEV - Sieve Analysis 35-325 Wet

| TOT | 35M | 48M | |

| 1 | 950 | 7.5 | 12.5 |

XML (to paste into Insight)

Born: 2020-07-03, Modified: 2020-08-18 11:01:44