Project Name

Saskatchewan Clays Testing Program

Project Codenumber

UnAssigned

Notes

Received from Dave Edgerton, Nov 16, 2020.

These were only slaked and propeller mixed as a slurry. No pregrinding of the powder was done. No barium was added to precipitate soluble salts.

Notes:

The Flintoft quarry has been mined but the strata continues over a wide area so a bit of simple surveying is in order.

The Halbrite deposit is on PFRA land. They were open the Dave getting a few pickup loads and it would be possible to write up a contract with them with some compensation to get access to the stockpile.

Pictures

Flintoft Quarry #2004

Ball Clay

|

Code # L4383 |

Notes

Under 2026, over 2027

Similar to Plainsman 3B, but cleaner and more vitreous, a vitreous ball clay. This is the most promising of all the clays. It fires to porcelain density at cone 6. And is highly plastic. Yet dries very well. And fires with no speckle, not even in reduction. It matures at cone 6 yet is still stable at cone 10!

However the fired shrinkage is high across the entire range. The drying shrinkage could to be cut with a non-plastic filler like Plainsman 3D.

Pictures

L4383 Fired bars (cone 10R downward)

Cone 10 all the way down to cone 6.

L4383 closeup of plastic material surface

L4383 DFAC disk dried

L4383 Fired tile, DFAC disk Cone 10R

G1947U Working normally at cone 10R

This is a standard glaze, it has not crazed on this clay so we know it does not have a higher-than typical pottery stoneware thermal expansion. It has not shivered either, so it does not have a significantly lower-than-typical expansion either.

L4383 with G2926B clear at cone 6

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 12 | 90.8 | 82.84 | 29.42 | 29.42 | 10.5R | 9.2% | 8.8% | 0.0% |

| 10 | 90.79 | 82.51 | 29.1 | 29.11 | 10 | 9.2% | 9.1% | 0.0% |

| 9 | 90.95 | 82.43 | 29.85 | 29.85 | 8.8 | 9.1% | 9.4% | 0.0% |

| 8 | 90.84 | 82.64 | 29.95 | 29.93 | 7.8 | 9.2% | 9.0% | -0.1% |

| 7 | 90.62 | 82.42 | 30.38 | 30.38 | 6.8 | 9.4% | 9.0% | 0.0% |

| 6 | 90.62 | 82.56 | 29.87 | 29.87 | 5.7 | 9.4% | 8.9% | 0.0% |

| 5 | 91.52 | 84.54 | 28.43 | 28.78 | 4.8 | 8.5% | 7.6% | 1.2% |

| 4 | 91.42 | 84.73 | 29.93 | 31.34 | 4.0 | 8.6% | 7.3% | 4.7% |

| 3 | 91.17 | 85.39 | 29.76 | 32.11 | 2.7 | 8.8% | 6.3% | 7.9% |

| 2 | 91 | 85.73 | 30.2 | 32.88 | 2.0 | 9.0% | 5.8% | 8.9% |

| 1 | 91.1 | 86.13 | 30.91 | 33.92 | 1.0 | 8.9% | 5.5% | 9.7% |

SIEV - Sieve Analysis 35-325 Wet

| TOT | 48M | 65M | 100M | 150M | |

| 1 | 46 | tr | tr | tr | tr |

LDW - LOI/Density/Water Content

| WWGT | DWGT | FWGT | H2O | LOI | DENS | |

| 1 | 29.11 | 20.36 | 18.43 | 30.1% | 9.5% |

XML (to paste into Insight)

Born: 2020-11-24, Modified: 2024-12-02 14:33:47

Blue Hills Quarry #2020

|

Code # L4377 |

Notes

Outcrop. Thickness: 2 ft.

50.103267, -105.420278

A plastic, non-refractory ball clay. Very clean burning. Medium soluble salts. Drying shrinkage is high. This could make up 50% of a stoneware body recipe.

See notes in Plainsman people for Dave Edgerton

Pictures

L4377 lumps

+70 mesh material

L4377 DFAC disk dried

L4377 Fired tile, DFAC disk Cone 10R

L4377 Fired bars (cone 10R downward)

G1947U Working normally at cone 10R

This is a standard glaze, it has not crazed on this clay so we know it does not have a higher-than typical pottery stoneware thermal expansion. It has not shivered either, so it does not have a significantly lower-than-typical expansion either.

With RavenTalc at 10R

Untitled

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 12 | 91.5 | 84.44 | 30.44 | 31.46 | 10.5R | 8.5% | 7.7% | 3.4% |

| 10 | 91.82 | 84.2 | 28.48 | 30.12 | 10 | 8.2% | 8.3% | 5.8% |

| 9 | 91.46 | 84.21 | 31.25 | 32.28 | 8.8 | 8.5% | 7.9% | 3.3% |

| 8 | 91.5 | 84.13 | 30.61 | 31.78 | 7.8 | 8.5% | 8.1% | 3.8% |

| 7 | 91.41 | 84.39 | 30.44 | 32.14 | 6.8 | 8.6% | 7.7% | 5.6% |

| 6 | 91.38 | 85.07 | 29.38 | 31.48 | 5.7 | 8.6% | 6.9% | 7.1% |

SIEV - Sieve Analysis 35-325 Wet

| TOT | 48M | 65M | 100M | 150M | |

| 1 | 74.5 | 0.14 | 0.06 | 0.2 | 0.21 |

LDW - LOI/Density/Water Content

| WWGT | DWGT | FWGT | H2O | LOI | DENS | |

| 1 | 34.15 | 24.88 | 22.27 | 27.1% | 10.5% |

XML (to paste into Insight)

Born: 2020-11-18, Modified: 2024-12-02 14:33:02

Flintoff Quarry - #2026

Layer Under 2023

|

Code # L4376 |

Notes

Thickness 2-3039;

A plastic and clean burning ball clay with some, but not excessive, soluble salts.

Same or similar to L4382

Pictures

L4376 lumps

L4376 closeup of plastic material surface

L4376 DFAC disk dried

L4376 Fired tile, DFAC disk Cone 10R

L4376 Fired bars (cone 10R downward)

G1947U shivering at cone 10R

This is a standard glaze, since it shivers it is lower than typical expansion. This is typical of a ball clay.

With RavenTalc at 10R - shivering at corners

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 12 | 91.7 | 85.59 | 32.24 | 33.78 | 10.5R | 8.3% | 6.7% | 4.8% |

| 10 | 91.21 | 84.88 | 32.87 | 34.03 | 10 | 8.8% | 6.9% | 3.5% |

| 9 | 91.6 | 85.52 | 32.28 | 33.75 | 8.8 | 8.4% | 6.6% | 4.6% |

| 8 | 91.88 | 86.51 | 32.92 | 34.77 | 7.8 | 8.1% | 5.8% | 5.6% |

| 7 | 92.15 | 86.69 | 32.55 | 34.80 | 6.8 | 7.8% | 5.9% | 6.9% |

| 6 | 91.8 | 86.79 | 32.51 | 35.18 | 5.7 | 8.2% | 5.5% | 8.2% |

| 5 | 91.58 | 86.85 | 32.25 | 35.06 | 4.8 | 8.4% | 5.2% | 8.7% |

SIEV - Sieve Analysis 35-325 Wet

| TOT | 48M | 65M | 100M | 150M | |

| 1 | 45.5 | tr | tr | 0.03 | 0.2 |

LDW - LOI/Density/Water Content

| WWGT | DWGT | FWGT | H2O | LOI | DENS | |

| 1 | 33.48 | 24.99 | 22.85 | 25.4% | 8.6% |

XML (to paste into Insight)

Born: 2020-11-18, Modified: 2021-10-27 20:35:16

Flintoft Quarry #2023

|

Code # L4373 |

Notes

Layer of white under cap layer. Flintoft quarry. Thickness: 1 1/2039;

A sandy, white burning refractory clay. Similar to Plainsman RE, but more plastic. Relatively free of particulate iron.

Need to do sieve analysis for this again to confirm, number appear too low.

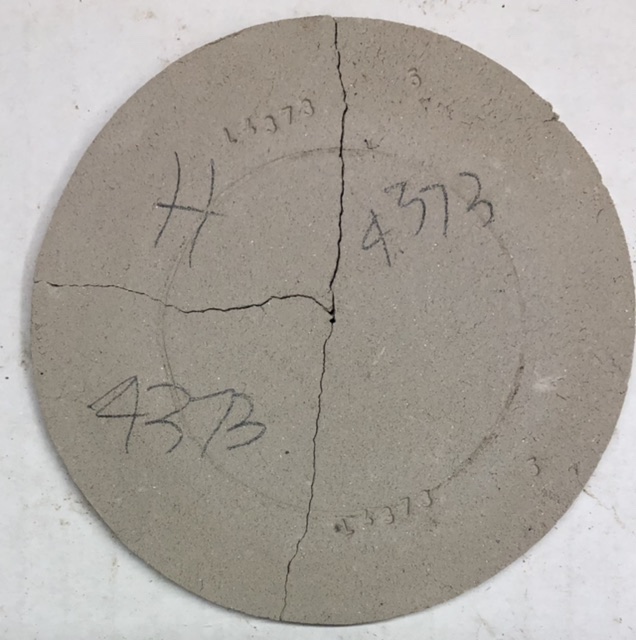

Pictures

L4373 lumps

L4373 closeup of plastic material surface

L4373 Flintoft Quarry +70 mesh

L4373 DFAC disk dried

L4373 Fired tile, DFAC disk Cone 10R

L4373 Flintoft Quarry #2023 fired bars

G1947U working normally

This is a standard glaze, it has not crazed on this clay so we know it does not have a higher-than typical pottery stoneware thermal expansion. It has not shivered either, so it does not have a significantly lower-than-typical expansion either.

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 12 | 93.66 | 87.68 | 33.78 | 38.88 | 10.5R | 6.3% | 6.4% | 15.1% |

| 7 | 93.56 | 89.54 | 35.97 | 41.2 | 10R | 6.4% | 4.3% | 14.5% |

| 10 | 93.42 | 89.08 | 36.37 | 41.39 | 10 | 6.6% | 4.6% | 13.8% |

| 9 | 93.34 | 89.18 | 36.12 | 41.33 | 8.8 | 6.7% | 4.5% | 14.4% |

| 8 | 93.44 | 89.71 | 35.26 | 40.8 | 7.8 | 6.6% | 4.0% | 15.7% |

| 6 | 93.4 | 90.41 | 34.78 | 40.59 | 5.8 | 6.6% | 3.2% | 16.7% |

| 5 | 93.67 | 6.3% |

SOLU - Soluble Salts

| DRY | |

| 1 | VLight |

DFAC - Drying Factor

| DFAC | SOLD | |

| 1 | A000 | NIL |

SIEV - Sieve Analysis 35-325 Wet

| TOT | 48M | 65M | 100M | 150M | |

| 1 | 67.0 | 0.03 | 0.06 | 0.31 | 3.12 |

| 2 | 70 | tr | 0.07 | 0.41 | 5.21 |

LDW - LOI/Density/Water Content

| WWGT | DWGT | FWGT | H2O | LOI | DENS | |

| 1 | 33.73 | 25.9 | 23.87 | 23.2% | 7.8% |

XML (to paste into Insight)

Born: 2020-11-16, Modified: 2020-12-21 20:00:37

Flintoft Quarry #2024

Ball Clay Cover

|

Code # L4379 |

Notes

A few rocks

6’ thick

A buff burning refractory stoneware. Plasticity similar to a standard throwing body. Fired speckle at cone 10R. Needs 10-15% feldspar to produce a cone 10 stoneware.

Pictures

L4379 Flintoft Quarry #2024 raw lumps

L4379 closeup of plastic material surface

L4397 70mesh+ particles

L4379 DFAC disk dried

L4379 Fired tile, DFAC disk Cone 10R

L4379 Fired bars (cone 10Rdownward)

With RavenTalc at 10R

With RavenTalc at 10R

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 12 | 93.35 | 86.42 | 36.7 | 39.48 | 10.5R | 6.7% | 7.4% | 7.6% |

| 10 | 93.32 | 85.36 | 36.24 | 38.36 | 10 | 6.7% | 8.5% | 5.8% |

| 9 | 93.27 | 85.43 | 34.84 | 37.06 | 8.8 | 6.7% | 8.4% | 6.4% |

| 8 | 93.39 | 85.9 | 34.44 | 37.02 | 7.8 | 6.6% | 8.0% | 7.5% |

| 7 | 93.24 | 85.99 | 36.17 | 39.02 | 6.8 | 6.8% | 7.8% | 7.9% |

| 6 | 93.24 | 86.66 | 35.69 | 38.91 | 5.7 | 6.8% | 7.1% | 9.0% |

SIEV - Sieve Analysis 35-325 Wet

| TOT | 48M | 65M | 100M | 150M | |

| 1 | 50 | 0.1 | 0.14 | 0.38 | 0.82 |

LDW - LOI/Density/Water Content

| WWGT | DWGT | FWGT | H2O | LOI | DENS | |

| 1 | 28.81 | 22.39 | 20.17 | 22.3% | 9.9% |

XML (to paste into Insight)

Born: 2020-11-22, Modified: 2021-10-27 20:34:10

Flintoft Quarry #2025

|

Code # L4371 |

Notes

Black clay under sample 2023

Thickness: 12 inches

In the wet state this looks and feels like Plainsman 3C. It is very plastic. Slakes down easily.

Feels, dries and fires like a ball clay.

Pictures

Lump form of L4371

Most lumps were 1" or smaller.

L4373 DFAC disk shows some soluble salts

L4371 Fired tile, DFAC disk Cone 10R

L4371 Fired bars (cone 10R downward)

G1947U glaze shivers, has dry surface -Cone 10R

This is a standard glaze, since it shivers it is lower than typical expansion. This is typical of a ball clay.

With RavenTalc 10R

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 12 | 91.65 | 86.32 | 37.33 | 38.89 | 10.5R | 8.3% | 5.8% | 4.2% |

| 10 | 91.51 | 85.83 | 37.52 | 38.95 | 10 | 8.5% | 6.2% | 3.8% |

| 9 | 91.71 | 86.02 | 37.25 | 38.85 | 8.8 | 8.3% | 6.2% | 4.3% |

| 8 | 91.8 | 86.68 | 37.6 | 39.57 | 7.8 | 8.2% | 5.6% | 5.2% |

| 7 | 91.9 | 86.77 | 36.15 | 38.21 | 6.8 | 8.1% | 5.6% | 5.7% |

| 6 | 92.17 | 87.2 | 35.36 | 37.49 | 5.8 | 7.8% | 5.4% | 6.0% |

DFAC - Drying Factor

| DFAC | SOLD | |

| 13 | C130+ | MEDIUM |

SIEV - Sieve Analysis 35-325 Wet

| TOT | 35M | 48M | 65M | 100M | 150M | |

| 1 | 64.98 | .21 | .03 | .34 | 2.06 | 0.5 |

LDW - LOI/Density/Water Content

| WWGT | DWGT | FWGT | H2O | LOI | DENS | |

| 1 | 35.84 | 27.3 | 24.89 | 23.8% | 8.8% |

XML (to paste into Insight)

Born: 2020-11-16, Modified: 2021-10-27 20:12:50

Flintoft Quarry #2027

Base Layer

|

Code # L4374 |

Notes

Under 2026

Several layers between 2026 and 2027

Sandy, yet sample arrived in three large lumps.

Very sandy like RE. But plastic enough to form with no problem. Refractory.

Pictures

L4374 lumps

L4374 closeup of plastic material surface

L4374 DFAC disk dried

L4374 Fired tile, DFAC disk Cone 10R

L4374 Fired bars (cone 10R downward)

G1947U working ok but less glossy at cone 10R

This is a standard glaze, it does not crazed on this clay so we know it does not have a higher-than typical pottery stoneware thermal expansion. It has not shivered either, so it does not have a significantly lower-than-typical expansion either.

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 12 | 94.5 | 93.19 | 36.89 | 43.86 | 10.5R | 5.5% | 1.4% | 18.9% |

| 10 | 94.54 | 92.78 | 38.28 | 45.46 | 10 | 5.5% | 1.9% | 18.8% |

| 9 | 94.63 | 93.1 | 37.85 | 45.12 | 8.8 | 5.4% | 1.6% | 19.2% |

| 8 | 94.35 | 93.2 | 38.29 | 45.74 | 7.8 | 5.7% | 1.2% | 19.5% |

| 7 | 94.45 | 93.13 | 37.98 | 45.65 | 6.8 | 5.6% | 1.4% | 20.2% |

| 6 | 94.45 | 93.21 | 36.83 | 44.29 | 5.7 | 5.6% | 1.3% | 20.3% |

DFAC - Drying Factor

| DFAC | SOLD | |

| 1 | A000 | light |

SIEV - Sieve Analysis 35-325 Wet

| TOT | 48M | 65M | 100M | 150M | |

| 1 | 87 | 0.13 | 0.83 | 22.03 | 13.14 |

LDW - LOI/Density/Water Content

| WWGT | DWGT | FWGT | H2O | LOI | DENS | |

| 1 | 37.73 | 29.78 | 27.96 | 21.1% | 6.1% |

XML (to paste into Insight)

Born: 2020-11-18, Modified: 2020-12-13 20:18:34

Flintoft Quarry #2029

Across Valley

|

Code # L4382 |

Notes

No overburden

Possibly same as #2026 L4376

An addition of talc could mature it at cone 8 (e.g. 3%).

Or, maybe 15% feldspar would cut plasticity and vitrify it at cone 10.

Pictures

L4382 closeup of plastic material surface

L4382 DFAC disk dried

L4382 Fired tile, DFAC disk Cone 10R

L4382 Fired bars (cone 10R downward)

G1947U Working normally at cone 10R

This is a standard glaze, it has not crazed on this clay so we know it does not have a higher-than typical pottery stoneware thermal expansion. It has not shivered either, so it does not have a significantly lower-than-typical expansion either.

With RavenTalc at 10R

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 12 | 91.4 | 85.04 | 28.88 | 29.99 | 10.5R | 8.6% | 7.0% | 3.8% |

| 10 | 91.52 | 84.3 | 30.31 | 31.07 | 10 | 8.5% | 7.9% | 2.5% |

| 9 | 91.21 | 84.4 | 31.09 | 32.27 | 8.8 | 8.8% | 7.5% | 3.8% |

| 8 | 91.33 | 84.95 | 31.54 | 33.03 | 7.8 | 8.7% | 7.0% | 4.7% |

| 7 | 91.46 | 85.32 | 31.89 | 33.78 | 6.8 | 8.5% | 6.7% | 5.9% |

| 6 | 91.45 | 85.71 | 32.72 | 35.01 | 5.7 | 8.6% | 6.3% | 7.0% |

SIEV - Sieve Analysis 35-325 Wet

| TOT | 48M | 65M | 100M | 150M | |

| 1 | 45 | tr | tr | 0.04 | 0.04 |

LDW - LOI/Density/Water Content

| WWGT | DWGT | FWGT | H2O | LOI | DENS | |

| 1 | 33.97 | 24.62 | 22.41 | 27.5% | 9.0% |

XML (to paste into Insight)

Born: 2020-11-22, Modified: 2021-10-27 20:36:50

Blue Hills Quarry #2001

|

Code # L4378 |

Notes

3 ft thick

A refractory stoneware. Light burning with some iron specks.

Plasticity typical of a pottery clay for throwing. Fairly clean. With 5-10% feldspar this could be a good stoneware for cone 10.

Pictures

L4378 Blue Hills Quarry #2001 raw clay

+70 mesh material

L4371 DFAC disk dried

L4378 Fired DFAC disk Cone 10R

G1947U Working normally at cone 10R

This is a standard glaze, it has not crazed on this clay so we know it does not have a higher-than typical pottery stoneware thermal expansion. It has not shivered either, so it does not have a significantly lower-than-typical expansion either.

L4378 Fired bars (cone 10R downward)

With RavenTalc at 10R

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 12 | 92.8 | 87.38 | 34.95 | 37.20 | 10.5R | 7.2% | 5.8% | 6.4% |

| 10 | 92.79 | 86.94 | 36.12 | 37.83 | 10 | 7.2% | 6.3% | 4.7% |

| 9 | 92.85 | 87.25 | 36.63 | 38.83 | 8.8 | 7.2% | 6.0% | 6.0% |

| 8 | 92.81 | 87.63 | 37.37 | 39.93 | 7.8 | 7.2% | 5.6% | 6.9% |

| 7 | 92.74 | 87.9 | 36.92 | 40.03 | 6.8 | 7.3% | 5.2% | 8.4% |

| 6 | 92.42 | 87.82 | 36.11 | 38.48 | 5.7 | 7.6% | 5.0% | 6.6% |

DFAC - Drying Factor

| DFAC | SOLD | |

| 1 | C110 | Light |

SIEV - Sieve Analysis 35-325 Wet

| TOT | 48M | 65M | 100M | 150M | |

| 1 | 50.75 | 0.16 | .04 | 0.13 | 0.53 |

LDW - LOI/Density/Water Content

| WWGT | DWGT | FWGT | H2O | LOI | DENS | |

| 1 | 17.86 | 13.53 | 12.43 | 24.2% | 8.1% |

XML (to paste into Insight)

Born: 2020-11-19, Modified: 2021-10-27 20:29:41

Blue Hills Quarry #2018

4’ layer

|

Code # L4380 |

Notes

Screened to 35#

I was told this is the same as #2001 L4378, but not according to these tests.

A fireclay. High porosity through the firing range. Good plasticity. Low fired shrinkage. This would be usable in ceramics, in amounts as high as 50% in recipes.

Dave dug #2018 and #2001 3 years apart, possibly not quite in the same location. He remembers 2001 was hard and blocky when dug and 2018 was a bit more crumbly. The two locations are within 100 feet of each other.

Pictures

L4380 closeup of plastic material surface

L4380 +50mesh material

L4380 DFAC disk dried

L4380 Fired tile, DFAC disk Cone 10R

G1947U Working normally at cone 10R

This is a standard glaze, it has not crazed on this clay so we know it does not have a higher-than typical pottery stoneware thermal expansion. It has not shivered either, so it does not have a significantly lower-than-typical expansion either.

L4380 Fired bars (cone 10R downward)

2021 Eastern Sask clay H550 test mugs

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 12 | 92.7 | 89.07 | 34.92 | 38.85 | 10.5R | 7.3% | 3.9% | 11.3% |

| 10 | 92.85 | 88.67 | 35.06 | 38.64 | 10 | 7.2% | 4.5% | 10.2% |

| 9 | 92.66 | 88.7 | 35.27 | 39.05 | 8.8 | 7.3% | 4.3% | 10.7% |

| 8 | 92.61 | 88.84 | 35.6 | 39.83 | 7.8 | 7.4% | 4.1% | 11.9% |

| 7 | 92.78 | 88.97 | 34.82 | 39.16 | 6.8 | 7.2% | 4.1% | 12.5% |

| 6 | 92.66 | 89.21 | 33.94 | 38.40 | 5.7 | 7.3% | 3.7% | 13.1% |

SIEV - Sieve Analysis 35-325 Wet

| TOT | 48M | 65M | 100M | 150M | |

| 1 | 79.0 | 0.08 | 0.29 | 0.63 | 2.34 |

LDW - LOI/Density/Water Content

| WWGT | DWGT | FWGT | H2O | LOI | DENS | |

| 1 | 37.95 | 28.73 | 26.36 | 24.3% | 8.2% |

XML (to paste into Insight)

Born: 2020-11-22, Modified: 2021-04-11 08:16:46

Blue Hills Quarry #2021

Fireclay

|

Code # L4375 |

Notes

Previously mined for Claybank brick plant.

An exceptionally refractory material. With lower drying shrinkage. This could likely be used pure to make firebricks. Good firebricks cost more than $5 each and if they are the insulating type, they are light and use very little clay.

Looks the Plainsman RE sand that we mine at Ravenscrag, but this much more plastic, no problem at all rolling and making test specimens. Very pleasant feel. That means this has more kaolin and less sand than our material.

Some iron particulates.

The landowner is curious to see if it has any commercial value. There appears to be no stockpile.

Pictures

Lump material L4374

Most of the material was quite fine, few lumps. It weathers down more than the other samples.

Closeup of plastic L4374 material

+50 mesh material

L4375 DFAC disk dried

L4375 Fired tile, DFAC disk Cone 10R

L4375 Fired bars (cone 10R downward)

G1947U Working normally at cone 10R

This is a standard glaze, it has not crazed on this clay so we know it does not have a higher-than typical pottery stoneware thermal expansion. It has not shivered either, so it does not have a significantly lower-than-typical expansion either.

With RavenTalc at 10R

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 12 | 94.31 | 92.08 | 36.85 | 43.13 | 10.5R | 5.7% | 2.4% | 17.0% |

| 10 | 93.83 | 91.15 | 38.07 | 44.31 | 10 | 6.2% | 2.9% | 16.4% |

| 9 | 93.75 | 91.17 | 38.05 | 44.47 | 8.8 | 6.3% | 2.8% | 16.9% |

| 8 | 93.49 | 91.39 | 37.41 | 43.92 | 7.8 | 6.5% | 2.2% | 17.4% |

| 7 | 93.63 | 91.7 | 36.64 | 43.29 | 6.8 | 6.4% | 2.1% | 18.1% |

| 6 | 93.51 | 91.74 | 36.44 | 43.19 | 5.8 | 6.5% | 1.9% | 18.5% |

DFAC - Drying Factor

| DFAC | SOLD | |

| 1 | A000 | nil |

SIEV - Sieve Analysis 35-325 Wet

| TOT | 35M | 48M | 65M | 100M | |

| 1 | 55.74 | 0.63 | 0.24 | 1.72 | .06 |

LDW - LOI/Density/Water Content

| WWGT | DWGT | FWGT | H2O | LOI | DENS | |

| 1 | 33.95 | 26.44 | 24.52 | 22.1% | 7.3% |

XML (to paste into Insight)

Born: 2020-11-17, Modified: 2021-10-27 20:31:41

Halbrite kaolin #2002

|

Code # L4381 |

Notes

The Halbrite deposit is on PFRA land. They were open the Dave getting a few pickup loads and it would be possible to write up a contract with them with some compensation to get access to the stockpile.

Washed with an excess of water and run it through a 12039; long riffle and then into a cloth lined drying trough. Slurry water content was reduced and half a cubic yard was blended. About 50% was removed as sand.

A vitreous and plastic kaolin. Would make a ivory-burning cone 10 porcelain with about 10% feldspar addition. No other additions may be needed if it contains enough quartz (not even bentonite).

The drying shrinkage is high yet the drying performance is good, very unusual!

Pictures

L4381 Halbrite kaolin #2002 raw lumps

L4381 closeup of plastic material surface

L4381 DFAC disk dried

L4381 Fired tile, DFAC disk Cone 10R

L4381 Fired bars (cone 10R downward)

G1947U Working normally at cone 10R

This is a standard glaze, it has not crazed on this clay so we know it does not have a higher-than typical pottery stoneware thermal expansion. It has not shivered either, so it does not have a significantly lower-than-typical expansion either.

With RavenTalc at 10R

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 12 | 92.5 | 80.96 | 30.25 | 31.17 | 10.5R | 7.5% | 12.5% | 3.0% |

| 10 | 92.37 | 81.47 | 29.26 | 30.69 | 10 | 7.6% | 11.8% | 4.9% |

| 9 | 92.33 | 82 | 28.81 | 30.40 | 8.8 | 7.7% | 11.2% | 5.5% |

| 8 | 92.46 | 82.78 | 28.33 | 30.45 | 7.8 | 7.5% | 10.5% | 7.5% |

| 7 | 92.75 | 83.49 | 27.87 | 30.23 | 6.8 | 7.3% | 10.0% | 8.5% |

| 6 | 92.6 | 83.88 | 27.9 | 30.60 | 5.7 | 7.4% | 9.4% | 9.7% |

DFAC - Drying Factor

| DFAC | SOLD | |

| 2 | A000 | Heavy |

SIEV - Sieve Analysis 35-325 Wet

| TOT | 48M | 65M | 100M | 150M | |

| 1 | 48.3 | 0 | 0 | 0 | 0 |

LDW - LOI/Density/Water Content

| WWGT | DWGT | FWGT | H2O | LOI | DENS | |

| 1 | 31.8 | 22.59 | 19.82 | 29.0% | 12.3% |

XML (to paste into Insight)

Born: 2020-11-22, Modified: 2023-02-28 15:03:18