Project Name

Zero3 Low Temperature Bodies

Project Codenumber

UnAssigned

Notes

The way to achieve high fired strength at low temperatures has long been known: frit additions. But frit is far more expensive than typical body materials and low-fire did not seem a logical place to make stoneware when it comes so natural at cone 6 and 10. But imagine making ware of superior strength and density only a cone or two above your usual bisque temperature! And there are no sacrifices in workability, these bodies are highly plastic. The underglazes paint on very well.

Why was cone 03 chosen? Because 04 is too low and 02 is too high. Almost any low fire underglaze, glaze or overglaze will still work at cone 03. Also it is low enough to still develop good terra cotta red color and bubble free glazes but high enough that minimal frit is needed to densify it.

March 2022: We are working on a much whiter version of the engobe, L3685Z2. And two other glaze recipes, G1916Q and G3879. And moving this down to cone 04 (aka Zero4).

URLs

Zero3 Porcelain - Experimental

|

Code # L3924C |

Location BOX48 |

Batch # -2 |

| Materials | Amt | Units | |

|---|---|---|---|

| New Zealand Kaolin | 227.000 | KG | 48.54% |

| Ferro Frit 3110 | 300.000 | LB | 29.10% |

| Silica | 200.000 | LB | 19.40% |

| VeeGum T | 30.000 | LB | 2.91% |

| Mason 6336 Blue Stain | 250.000 | GM | 0.05% |

Total:467,658.00 (R)

Notes

This body is not available for sale. It is a fritware porcelain (frit is the flux instead of the traditional feldspar). Frits melt far low temperatures so this supercharges the firing maturity.

A long series of test mixes in search of a blend of North American materials found that the glassy phase of the frit amplifies the color of any iron in the kaolin (even tiny amounts). No kaolins available to us were suitable except Grolleg and New Zealand Kaolin (it contains only 0.15% iron). NZK is short, so lots of VeeGum is needed. A pinkish color still remains making it necessary to add a small amount of blue stain (giving it the color of cone 10 reduction porcelain). Propeller mix it very thoroughly and be careful about substituting that stain, agglomerates during mixing produce ugly blue fired specks!

This body pairs with G2931K clear glaze (the fully fritted version of G2931F) and a drop-and-soak firing glaze schedule.

The secrets of this body are thus:

-The 30% frit: Frit is expensive but it makes the impossible possible!

-The NZ Kaolin: The whitest available in the world.

-The VeeGum: Super plastic super-white. Bentone also works.

-The silica for glaze fit and as a structural framework.

As noted, this body will be among the most plastic you have ever used (of any kind). But this is only true if it is stiff enough. Do not use it soft, the shrinkage will be much higher and you risk drying cracks.

Higher than normal firing shrinkage is a part of using this type of body. But that also indicates very high density and strength.

This frit is slightly soluble. That means that on storage it will affect stiffness in the plastic clay or affect the rheology of a casting slip. It can affect plaster and your plaster table.

If we were to manufacture this is could cost $150 a box. But before dismissing this think about the advantages of using it for making smaller pieces:

-Fast firing: As little as 3 hours cold-to-cold.

-The appearance of cone 10R but with far brighter colors.

-High strength.

-Throw ware ultra thin and light.

-A perfectly fitted ultra-clear dipping glaze that is far cheaper to make than commercial glazes.

-Dramatic reduction in wear-and-tear on kiln elements and energy usage.

A final note: Because this body matures at such a low temperature it needs to be bisqued much lower (around 1500F. if ware is not absorbent enough fire lower).

Units-of-measure: I have specified 50 lb bags to fill the needed amount for the NZ kaolin, however it comes in 20kg bags. But you are likely mixing in grams or ounces so just refer to the percentage column.

Batch Ticket Notes

Notes for this ticket.

Pictures

L3924B Frit-ware porcelain mug with G2931K glaze

The only difference between this and L3924C is the amount of blue stain. This has 0.07% and C has 0.05%.

Fired at 03 with G2931K glaze (it is the all-frit version of G2931F). The result is stunning! Fired strength is incredible. It can withstand immersion into icewater from 300F. Glaze is absolutely crystal clear, underglaze is the clearest and brightest I have ever seen! Very pleasant reduction-like blue white color.

Zero3 Porcelain translucency

Zero3 Porcelain as engobe Zero3 Terracotta does not work

3924C on 3724N - cracking badly because the fired shrinkage is 10% vs body of 6%.

L3924B cone 03 porcelain (right) vs. cone 10R body

The mug on the left is a Grolleg Porcelain, fired to cone 10 with G1947U glaze. This body (right) appears greyer on the photo that it actually is. The glaze is G2931F. Admittedly, the Grolleg does has an ice-blue shade that is more pleasant.

G2931K glazed Zero3 Porcelain Mugs

P700 vs. Zero3 vs. Polar Ice

P700 isa Grolleg porcelain fired at cone 10R.

Zero3 is a cone 03 fritware body fired at cone 03 oxidation.

Polar Ice is a New Zealand kaolin porcelain fired at cone 6 oxidation

All are zero porosity and very strong.

Be careful with type and percentage of stain

Normally I use Mason 6336, but the piece on the right in Mason 6300 Mazerine Blue. Obviously that blue is much more potent. So test with your blue stain before making a big batch of the porcelain.

Zero3 Porcelain 10 inch marbled bowl

Glaze is G2931K Zero3 clear. Cone 03 firing.

L3924C, D, E, F compared at cone 03

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 5 | 26.16 | 26.19 | 1.0 | 0.1% | ||||

| 4 | 93.46 | 83.32 | 32.29 | 32.33 | -2.2 | 6.5% | 10.8% | 0.1% |

| 3 | 93.58 | 83.6 | 34.21 | 34.24 | -3.0 | 6.4% | 10.7% | 0.1% |

| 1 | 94.84 | 84.16 | 35.02 | 35.32 | -4.0 | 5.2% | 11.3% | 0.9% |

| 2 | 94.84 | 83.81 | 37.08 | 37.11 | -4.0 | 5.2% | 11.6% | 0.1% |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Zero3 Porcelain - Experimental" id="95860" key="LN5Ew8kc" date="2022-04-06" codenum="L3924C" location="BOX48"> <recipelines> <recipeline material="New Zealand Kaolin" amount="227.000" tolerance="" unitabbr="KG"/> <recipeline material="Ferro Frit 3110" amount="300.000" tolerance="" unitabbr="LB"/> <recipeline material="Silica" amount="200.000" tolerance="" unitabbr="LB"/> <recipeline material="VeeGum T" amount="30.000" tolerance="" unitabbr="LB"/> <recipeline material="Mason 6336 Blue Stain" amount="250.000" tolerance="" unitabbr="GM"/> </recipelines> </recipe> </recipes>

Born: 2014-09-19, Modified: 2022-04-06 22:56:16

Zero3 Stoneware

For use with the Zero3 glaze and engobe

|

Code # L3724N2 |

Batch # -2 |

| Materials | Amt | Units | |

|---|---|---|---|

| Redart | 15.000 | 50BG | 71.29% |

| M23 Ball Clay | 4.000 | 50BG | 19.01% |

| Ferro Frit 3110 | 75.000 | LB | 7.13% |

| Bentonite | 25.000 | LB | 2.38% |

| Barium Carbonate | 2.000 | LB | 0.19% |

Total:477,179.60 (R)

|

Si:Al: 6.4:1 6.3 (Molar:5.6) 5.6 Cost 0.28 per kg |

Notes

The Zero3 recipes (plastic body, engobe, over glaze and firing schedule) are do-it-yourself, they are not in production anywhere.

Casting: Remove the bentonite.

People who used to use high temperature bodies will be most comfortable with this: Stoneware strength at thirteen cones lower! Using dipping glazes. Those who used to do brightly colored terra cotta ware will have more difficulty adapting to this. Most are accustomed to tolerating weak, porous, completely non-functional ware (fired at 06) to get bright colors and warping resistance during firing. That is not what this is about. Zero3 IS NOT TERRACOTTA OR EARTHENWARE. It vitrifies (the clay color is thus darker). Vitreous bodies warp much more easily so extreme shapes are not for this. Ware fired on stilts will warp.

This is called "Zero3" because it is fired at cone 03 (firing lower compromises strength). Any commercial underglaze rated for cone 06 should easily survive to 03.

The work flow in using the Zero3 system is different than for typical clay bodies. The creative effort is concentrated up to the leather hard stage, after that it is a matter of drying, bisque firing, dipping in clear and final firing.

Ware strength (and the higher price) comes from the added frit (which is a low melting glass that has been powderized), it melts and glues all particles into a strong matrix (for the white Zero3 porcelain four times the frit is is needed).

The Zero3 body (and engobe), mature so low that even at bisque temperatures they have begun to vitrify. Bisque fire ware around cone 010 to be absorbent enough for glazing (if you mistakenly bisque too high just heat ware to 200F and then dip it in the clear glaze). The traditional bisque-higher-glaze-lower method is not needed here since the drop-and-hold step on the glaze firing schedule will clear bubbles in the glaze and heal surface defects.

Zero3 Stoneware is plastic and very, very slick and smooth. It does not generate large amounts of slip on throwing (as do many terra cottas). Drying is fairly slow (because of the bentonite content). Dry hardness is excellent. You can get more plasticity if needed by increasing the bentonite (I tried doubling it, the drying shrinkage increased by about 1%).

Fired ware passes a 300F to ice-water to boiling water stress test without crazing or shivering (in our lab). Glazed ware has good resistance to thermal shock (when fired at cone 03).

The barium is optional, it is there to precipitate solubles. Try the recipe without it to see if you can tolerate the salts on the fired surface.

Slip Casting

Drop out the bentonite (adjust the ball clay as noted above). For 1000g of dry use about 420g water and 7.5 Darvan (for about 1.75 specific gravity). If the slip is gelling or too thick it is likely under-deflocculated, take a small amount out from the batch and experiment with adding more Darvan. It is more important to listen to your slip than a book.

To Make Traditional Terra Cotta: Try our L4170B recipe instead.

Pictures

L3724N decorated leather hard mugs

Crysanthos underglaze colors have been applied in multiple layers. These are not engobed on the inside.

12 minute pour gives 3.7mm wall thickness

This 14cm bowl was extracted from the mold in about 30 minutes. The thicker wall has the strength to pull itself away without cracking problems.

This was the standard recipe without the bentonite. If kaolin were substituted for the ball clay it would cast faster.

Zero3 N1 mugs

Zero mugs ready for bisque

Zero3 casting bowls (cone 06, 02)

Zero3 body with G2931F Zero3 glaze

The F version of the glaze employs Ulexite to source the boron (instead of frits). These Zero3 stoneware mugs were fired to cone 03 with underglazes. The right mug has the Zero3 engobe inside (under the glaze).

Zero3 stoneware N2 glaze

This is a year old. No crazing yet.

L3724N2 Zero3 stoneware with G2931K glaze

Fired cone 03. With various Amaco Velvet underglazes tested.

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 5 | 93.66 | 87.11 | 38.04 | 38.06 | 1.0 | 6.3% | 7.0% | 0.1% |

| 4 | 93.87 | 87.73 | 37.55 | 38.35 | -2.0 | 6.1% | 6.5% | 2.1% |

| 3 | 94.13 | 88.32 | 47.55 | 49.39 | -3.0 | 5.9% | 6.2% | 3.9% |

| 2 | 92.86 | 88.58 | 38.29 | 40.09 | -4.5 | 7.1% | 4.6% | 4.7% |

| 1 | 93.02 | 90.88 | 36.09 | 39.45 | -6.0 | 7.0% | 2.3% | 9.3% |

LDW - LOI/Density/Water Content

| WWGT | DWGT | FWGT | H2O | LOI | DENS | |

| 1 | 25.59 | 19.86 | 18.56 | 22.4% | 6.5% |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Zero3 Stoneware" keywords="For use with the Zero3 glaze and engobe" id="93157" key="HtvmBfrx" date="2022-04-06" codenum="L3724N2"> <recipelines> <recipeline material="Redart" amount="15.000" tolerance="" unitabbr="50BG"/> <recipeline material="M23 Ball Clay" amount="4.000" tolerance="" unitabbr="50BG"/> <recipeline material="Ferro Frit 3110" amount="75.000" tolerance="" unitabbr="LB"/> <recipeline material="Bentonite" amount="25.000" unitabbr="LB"/> <recipeline material="Barium Carbonate" amount="2.000" unitabbr="LB"/> </recipelines> </recipe> </recipes>

Born: 2015-01-28, Modified: 2022-04-06 23:09:23

Zero3 Engobe Recipe

For use with the Zero3 body and glaze

|

Code # L3685U1 |

Location BOX48 |

Batch # -2 |

| Materials | Amt | |

|---|---|---|

| Nepheline Syenite | 10.000 | 9.80% |

| Pioneer Kaolin | 42.000 | 41.18% |

| Ferro Frit 3110 | 25.000 | 24.51% |

| Silica | 20.000 | 19.61% |

| National Standard Bentonite | 5.000 | 4.90% |

Total:102.00

Notes

The Zero3 Engobe finds its inspiration in the ceramic tile industry. Thousands of tons of white engobe are applied to tiles made from red or brown burning bodies, after pressing, to prepare them for glazing. The white surface enables the use of glazes of any color.

This engobe is not required in the Zero3 system, but like tile, it is employed for practical reasons. A typical use case for functional ware is application to inside food surfaces at leather hard state (and covering with the clear transparent Zero3 glaze after bisque firing). Or, as in tile, application to the red-burning body, by dipping or painting, to create a white base onto which coloured underglaze decoration is done. If you are using this engobe on another clay body, especially if not firing to cone 03, do an EBCT test to be sure they are compatible (have the same firing shrinkage), adjust the frit percentage as needed.

This is an engobe, it must be applied at stiff leather-hard stage (if you apply it to dry or bisque it will flake off). It will rewet pieces and they will require significant time to re-stiffen to the same state. Even coverage can normally only be achieved by preparing a slurry of the correct rheological properties and dipping or pouring. It is vital that you have a good mixer and can effectively measure specific gravity. To mix this use the process described on the “Engobe” glossary page at the Digitalfire Reference Library. A paint-on version of this can be made by adding 500g powder engobe to a mix of 400g water and 75g of Laguna Gum Solution (makes 1 pint). This produces brush-stroke coverage, which can be very attractive.

A drop or two of Dettol might be needed to store this for long periods (to prevent bacteria or mold).

Recipe info: The silica helps match body thermal expansion and glaze fit. The frit makes the fired hardness of the engobe more closely match the body. Nepheline Syenite is included as a filler. The bentonite is needed for good adhesion to the leather hard body and for dry hardness.

Pictures

Engobe applied to leather-hard mug

This was done by simply filling and rotate-pouring the engobe, then pressing the lip into it. Since the engobe gels the mug could be turned over immediately without creating any drips.

Notice that the outer surface of the handle has been waxed to slow down its drying. This is because the engobe rewets the mug body, thereby setting it behind the handle. This mug has thin wall so this this rewet adds a day to the production process. This next day the brushwork is done on the outside.

Zero3 body with G2931F Zero3 glaze

The F version of the glaze employs Ulexite to source the boron (instead of frits). These Zero3 stoneware mugs were fired to cone 03 with underglazes. The right mug has the Zero3 engobe inside (under the glaze).

Pulling badly on L212 on EBCT at cone 04

Amaco white engobe vs. L3685U 15% white stain

Even with 15% white stain this engobe is not nearly as white (in the raw state) as the Amaco version. Need to experiment more with whiter kaolins and opacifer additions.

Variations

6100 - Red

1400 powder, 1067 water, 5.6 Darvan produced 1.52 SG. Too runny, took alot of epsom salts. Perhaps water could be reduced. Pulling badly at L212 on EBCT test.

Testdata

EBCT - Engobe Body Compatibility Test

| MATA | MATB | BNDR | BNFR | BCON | |

| 1 | engobe | L212 | 1.6mm | 15mm/engobe | 06 |

| 2 | engobe | L212 | 1.5mm | 10mm | 04 |

| 3 | engobe-brown | L212 | 3.3 | 03 |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Zero3 Engobe Recipe" keywords="For use with the Zero3 body and glaze" id="93335" key="e21FscN7" date="2021-02-01" codenum="L3685U1" location="BOX48"> <recipelines> <recipeline material="Nepheline Syenite" amount="10.000" tolerance=""/> <recipeline material="Pioneer Kaolin" amount="42.000" tolerance=""/> <recipeline material="Ferro Frit 3110" amount="25.000" tolerance=""/> <recipeline material="Silica" amount="20.000" tolerance=""/> <recipeline material="National Standard Bentonite" amount="5.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2014-11-04, Modified: 2021-02-01 16:04:10

Zero3 K Cone 03 Transparent Glaze

|

Code # G2931K |

Batch # -2 |

| Materials | Amt | |

|---|---|---|

| Ferro Frit 3195 | 25.000 | 26.32% |

| Ferro Frit 3134 | 33.000 | 34.74% |

| EPK | 20.000 | 21.05% |

| Ferro Frit 3249 | 10.000 | 10.53% |

| Ferro Frit 3110 | 7.000 | 7.37% |

Total:95.00

Auto Unity Formula

|

Si:Al: 6.1:1 7.4 (Molar:7.5) 3.1 Cost 0.24 per kg |

Notes

This recipe improved on the popular Worthington Gerstley-Borate-based low fire clear recipe. It targeted cone 03 to work best on Zero3 stoneware and porcelain. To fire lower (cone 06-04), consider G1916Q (or derivatives) instead.

Unlike its Worthington Clear predecessor, this does not become a bucket of jelly, does not crack on drying, does not go on unevenly or the wrong thickness, does not cloud up with boron blue or micro-bubbles when fired (because it has lower CaO) when used on the types of bodies discussed below. It is crystal clear and super glassy at cone 03.

If you liked the variegated appearance of the GB version, titanium dioxide can be added to this to produce even better variegation. For darker color rutile with do the same.

Low fire bodies span a wide range of thermal expansions. While Worthington clear (an ancestor of this recipe) melts to a good clear, its thermal expansion was too low. This recipe, G2931K, raises thermal expansion (by adding Na2O). The thermal expansion of Zero3 stoneware and porcelain are about the middle of the range, and they develop good glaze:glaze interfaces, so this recipe fits them well.

This glaze shivers on high-talc bodies and can craze on zero-talc porous ones. This recipe has three variations we have worked with, one of higher expansion (G2931H) and one of lower expansion (G2931L). Keep in mind that adding zircon and stains changes expansion.

Dipping ware in Zero3 Transparent is just so much easier than trying to paint on commercial, slow-drying clears. For us it naturally gels to a creamy consistency at around 1.53 specific gravity (in our circumstances). However it goes on too thick at that high a value, we have found the best all-around performance at 1.43 with enough Epsom Salts to gel it back up to a creamy thixotropic consistency (a few grams per gallon).

Pay special attention to the drop-and-hold firing schedule, especially if your clay body is not fine-grained. Use 04DSDH as a model.

To mix up 5 Kg use about 4.5 kg of water to get 6.5 litres of dipping glaze. To make a brushing glaze: For each 100g of powder mix start with 125 water, 1.5 CMC gum and 1.5 Veegum and thoroughly mix in a kitchen blender (add water if it gels too much). We find the about 330g of powder produces a 500ml (about 1 pint) jar.

To make colored versions add stains as needed (if stains cause micro-bubbling or orange peel surface include 2-3% zircopax).

Batch Ticket Notes

These notes were entered in the notes panel under "Batch Ticket Notes"

Pictures

G2931K on Zero3 Stoneware

Fired cone 03. Body is Zero3 stoneware.

Surface is perfect, even where thick. Ultra clear.

Survived three boil:ice cycles and one 300F:ice cycle without crazing.

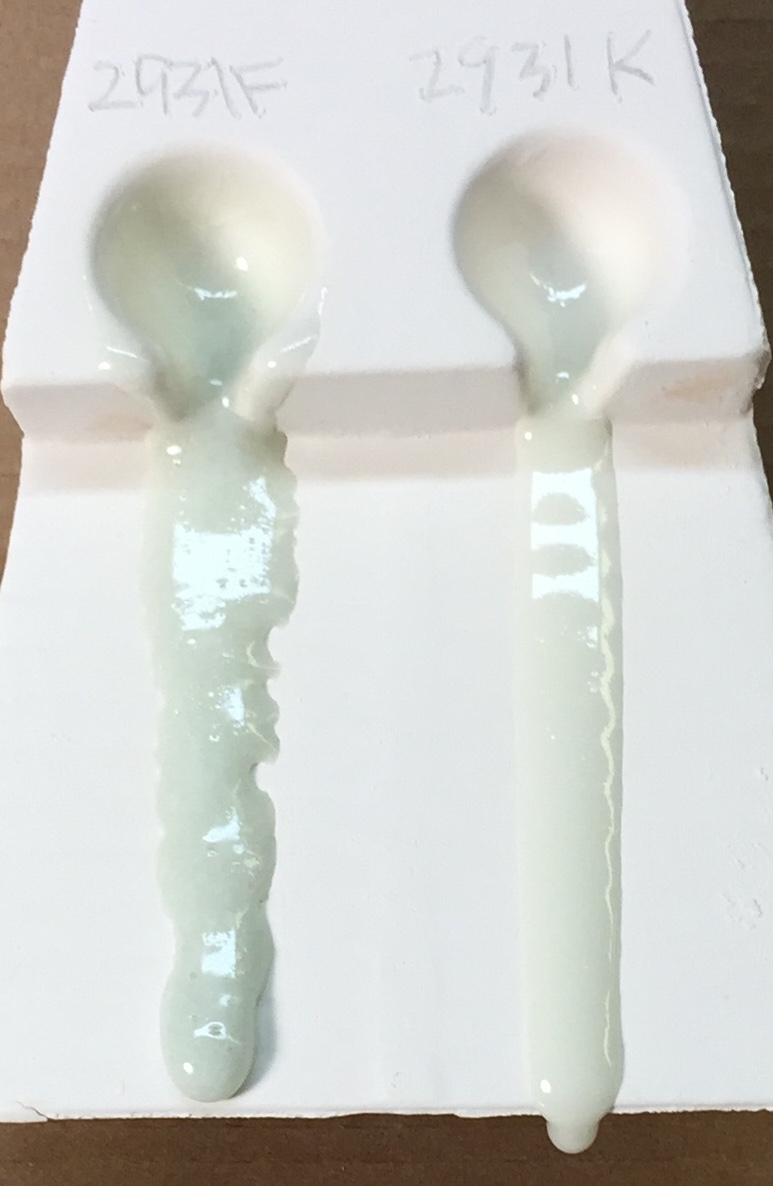

G2931F vs. G2931K on Polar Ice Low Fire

2931F was the Ulexite flused version of this recipe. The F survived three boil:ice cycles and 1 300F:ice cycle without crazing or shivering.

The K is slightly smoother, tiny dimples in the surface are fewer. It is also applied thicker.

G2931F vs G2931K fritted - terra cotta mugs cone 03

F was the Ulexite-fluxed version of this recipe.

G2931F vs G2931K flow test

These two recipes have the same chemistry, but K sources boron from frits rather than Ulexite. Notice how much less bubbles there are in the flow and how much more predictable the melting pattern is.

G2931F vs G2931K - Melted balls at cone 03

F, the Ulexite version, is obviously bubbling more, the percolation is causing the melt to spread out more on the tile. On the flow test is was less fluid.

Firing temperature is important for Zero3 glaze

This is G2931F on Plainsman Buffstone, L213, F100, L215. First column is cone 04, center is cone 03, right is cone 02. All exited the kiln without crazing except Buffstone at cone 04.

We subjected all of them to a 300F:IceWater thermal shock.

Buffstone crazed on all of them.

L215 and L212 Cone 04 crazed.

L213 was good but later the glaze was found to be under excessive compression, subject to shivering over underglazes.

At cone 02 there are some dimples and defects.

Three low fire bodies that need three clear glazes

Because of glaze fit. Left: Plainsman Buffstone, contains no talc, fires buff. Center: L212 (about 25% talc). Right: L213 (about 45% talc, fires whiter). Talc raises thermal expansion. The centre glaze is G2931K (Insight-live reports COE 7.4), it fits L215 (also Zero3 porcelain and stoneware). It crazes on Buffstone and shivers on L213 and L212. G2931L has lower expansion (to work on zero-talc porous bodies). G2931H is higher (for talc bodies like L213).

G2931K glaze precipitates things on storage

G2931K On L212 after a year

Some crazing starting.

K on L215 at cone 04

The thicker version is clouding. The thinner one has micro-pinholes. It needs a higher temperature.

G2931K o L215 - Cone 03, thick application

G2931K on L215 - Cone 03 fired in 30 minutes

Very transparent. No crazingafter many months.

G2931K on L215 - Cone 06

Milky (because cone 06 is underfired for this glaze). But only a little crazing after a year.

G2931K running on Zero3 Casting

This happened at cone 03 and 04. The G3879 (left) did not run. For some reason G2931K easy applies to thickly on this body.

This 1000 gram batch of glaze powde

This 1000 gram batch of glaze powder screened 80 mesh immediately after making, and allowed to sit for 3 months prior to usage.

The material in photo was screened out once again after the 3 month time lapse, (80 mesh once again).

The largest balls are approx. 2.5 mm. in diameter, and when these particles were screened out, and still perhaps slightly wet?, they were quite easy to break in half with your fingernail.

G1916Q (left) vs G2931K (right) at cone 04

On a terra cotta body, the G1916Q is performing better, there are less micro bubbles.

URLs

How to tune the thixotropy of a glaze

How to convert a d..o a brushing glaze

Typecodes

ST-Untitled typecode

Alternate Code Number:GS04-1

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Zero3 K Cone 03 Transparent Glaze" id="95671" key="ryaXtFno" date="2023-05-03" typecodes="ST" codenum="G2931K" picturebasename=""> <recipelines> <recipeline material="Ferro Frit 3195" amount="25.000" tolerance=""/> <recipeline material="Ferro Frit 3134" amount="33.000" tolerance=""/> <recipeline material="EPK" amount="20.000" tolerance=""/> <recipeline material="Ferro Frit 3249" amount="10.000" tolerance=""/> <recipeline material="Ferro Frit 3110" amount="7.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2006-03-16, Modified: 2023-05-03 20:54:14

Firing Schedule Name

Cone 03 hold-rise-drop-hold

Degrees (Fahrenheit or Celcius)

F

Schedule Type

Rate

Start Time and Temperature

8:01 am at 80F

Program

| Step | Degrees/Hr | Temperature Monitor |

Hold Time |

Accumulated hrs:min |

Time | Note |

|---|---|---|---|---|---|---|

| 1 | 400 | 240 | 60 | 1:24 | 9:25 am | |

| 2 | 350 | 1850 | 30 | 6:00 | 2:01 pm | |

| 3 | 108 | 1950 | 10 | 6:55 | 2:56 pm | |

| 4 | 500 | 1850 | 30 | 7:07 | 3:08 pm |

Notes

Used to glaze fire Zero3 porcelain and stoneware. However, there is a caution about bisquing these frit-containing bodies: They will vitrify in a typical firing, you must reduce the temperature to around 1500F (if ware is not absorbent enough fire lower). Note: this schedule is for the glaze firing, the previous two sentences simply referenced what is needed for the bisque.

This can start and finish more than once in a working day. Step 2 can often be done as fast as your kiln will go (cold-to-cold in three hours is possible).

The soak at 240F does not fracture ware even though it is above the boiling point of water. We find this is needed to be sure ware is sufficiently dry to withstand the rapid ascent to 1850. If your ware is thicker a slower ascent may be needed.

The 1850 soak on the way up clears the clouds of microbubbles. The 1850 soak on the way down heals the defects (blisters, pinholes) because the increasing viscosity is enough to overcome the surface tension holding bubbles from breaking).

It may be necessary to alter the last step if any imperfections are present. Try dropping to 1800 or 1750 and holding there. An additional step could be added to cool at 100F/hr down to 1500.