Project Name

White Engobe for Low Fire

Project Codenumber

UnAssigned

Notes

Low fire white engobes are typically used on terra cotta, especially tile. The whiteness depends not just on the percentage of zircon but also on the opacity. Engobe opacity is not like glaze opacity - engobes are applied in much thinner layers and the opacity depends on the degree of fired maturity (the whiteness comes from the zircon). If an engobe is begins to melt opacity is lost. That being said, as much melt as possible is needed to bond the engobe to the body. Physical bonding and drying properties also need to be right to get even application that dries without flaking or cracking.

Engobes applied at leather-hard stage, and having a drying shrinkage similar to the body, obviously bond the best. Application after dust pressing is second best. Third best is the application of white engobes to terra cotta bisque (ie. art tile). Adhesion and resistance to flaking and cracking is a much bigger issue here.

These recipes demonstrate the effort I went to to tune the firing shrinkage an engobe recipe to fire-fit specific bodies (e.g. L4170B). The secret was adding a small percentage of frit (typically much less than what appears in recipes found online). These engobes were applied to leather hard ware.

What if you must apply to bisque? There are three challenges:

-You must tune the white engobe to melt just enough to adhere but not so much that opacity is lost. Follow the pattern set here by trying different percentages of frit.

-You must achieve a recipe that dry-bonds well (without cracking or flaking). Typically the only way is to make it a brushing engobe, one containing CMC gum (although you might not be applying it by brushing). Here again, tuning will be necessary to have enough gum to bond well but not so much that drying is too slow.

-You must achieve a recipe having a compatible thermal expansion. Typically engobes have a COE that is too low - thus a high expansion frit, like Ferro 3110, is usually the best choice.

Pictures

Z2 White Cone 04 Engobe Base (no frit)

|

Code # L3685Z2 |

Batch # -2 |

| Materials | Amt | Units |

|---|---|---|

| Nepheline Syenite | 20.000 | GM |

| New Zealand Kaolin | 55.000 | GM |

| Silica | 25.000 | GM |

| Additions | Units | |

|---|---|---|

| Zircopax | 20.000 | GM |

Total:120.00 (R)

Notes

This is the product of a long development program that culminated in the realization that a super-white engobe requires using super-white kaolins and bentonites and plenty of Zircopax. Initially I did work attempting to apply this to bisque ware (adding 3% VeeGum, 1% CMC gum, double the water) but found that was misguided (since the engobe must fire-shrink and the body has already done so). Instead, this became a base to which I added small amounts of frit to increase firing shrinkage to match a body, it can be matched to bodies from low to medium temperature.

The opacity of this is exceptional. When made as a brushing version it works with one coat and no brush strokes are even visible!

As with other engobes, make this thixotropic this using vinegar or Epsom salts. To make it go on thick deflocculate it with Darvan. For a thin application add VeeGum, which will gel it enabling the addition of more water.

This recipe looks so good because it promises to enable the strength of terra cotta with the whiteness of porcelain. This, in turn, promises to provide white surfaces for brush work and transparent overglazes that produce brilliant gloss and colors not achievable at high temperatures.

Below is data on the fired shrinkage of this at ten temperatures! How do you use that data? An example: To fire at cone 2 the body needs to have around 3.6% fired shrinkage. We retested this engobe with 5% frit, L3685Z4, which increased maturity more than expected. The L3685Z5 improved that with a 3% frit, increasing firing shrinkage by 2%, which turned out to be good for the L4170B terra cotta.

Pictures

Cone 1-6 (bottom to third from top), cone 01, 02 at top

L3685Z1 and L3685Z2 at cone 04

L3685Z2, this improved version, is whiter. On Plainsman L210 fit is amazing is good (right).

The L3685Z1 (left) contains too much flux and it fire shrinking (the early stages of melting).

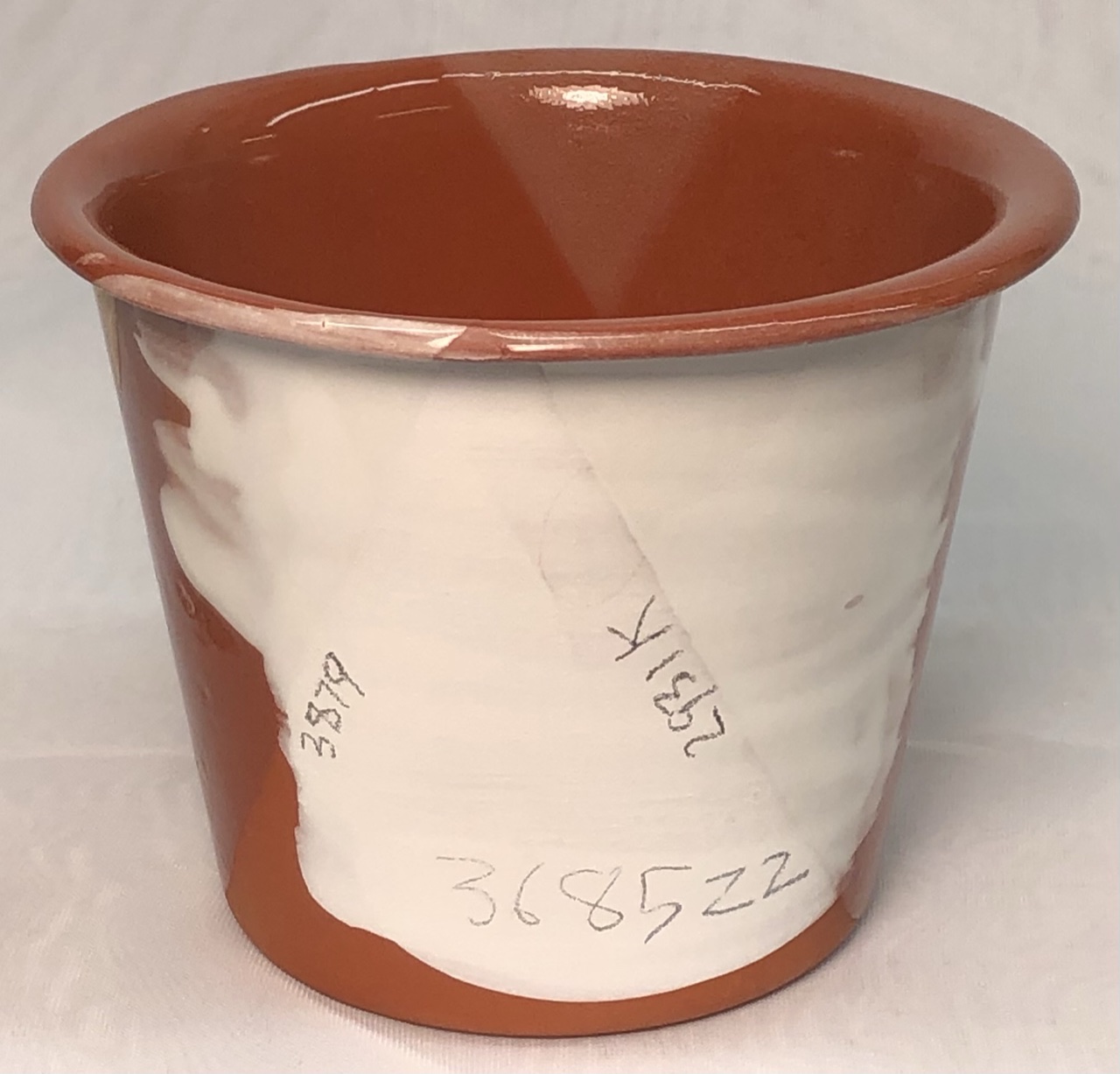

L4170B with L3685Z2 engobe

With the gum additions, it applied very evenly to the bisque (using a pour-in pour-our technique). The layer was very thin yet covers well. This was just an experiment to get even coverage, we recommend application of engobe to leather-hard ware.

Cone 04 L3685Z2 white engobe on L4170B

The colour is pure white, even when thinly applied. And it fits very well even though we are dipping pieces, like a glaze.

G2831K glaze (right) crazed after months. G3879 glaze (left) did not.

L215 with L3685Z2 engobe at cone 04

Although a very thin layer it completely covers terra cotta L215 and L210. Color is whiter than paper! Clear glazed surface is as white as porcelain. Used G1916Q and G3879 and clear overglazes, one fires more blue-white, not sure which.

On L215 cone 03+ shivers on rim

This is L3685Z2 engobe, it contains no frit and is not forming a good fire bond with the body.

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 8 | 95.9 | 87.03 | 39.91 | 41.86 | 8.0 | 4.1% | 9.2% | 4.9% |

| 7 | 95.75 | 87.59 | 38.95 | 41.32 | 7.0 | 4.3% | 8.5% | 6.1% |

| 6 | 96.04 | 88.42 | 39.64 | 42.94 | 6.0 | 4.0% | 7.9% | 8.3% |

| 5 | 95.79 | 88.96 | 39.78 | 43.8 | 5.0 | 4.2% | 7.1% | 10.1% |

| 4 | 95.92 | 89.61 | 40.55 | 45.15 | 4.0 | 4.1% | 6.6% | 11.3% |

| 3 | 96.05 | 91.84 | 39.98 | 45.88 | 3.0 | 4.0% | 4.4% | 14.8% |

| 2 | 96.06 | 92.58 | 39.98 | 46.7 | 2.0 | 3.9% | 3.6% | 16.8% |

| 1 | 96.09 | 93.2 | 38.06 | 44.96 | 1.0 | 3.9% | 3.0% | 18.1% |

| 9 | 95.82 | 93.54 | 37.68 | 47.31 | -1.0 | 4.2% | 2.4% | 25.6% |

| 10 | 95.79 | 93.78 | 38.32 | 46.27 | -2.0 | 4.2% | 2.1% | 20.7% |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Z2 White Cone 04 Engobe Base (no frit)" id="191314" key="JJtfnior" date="2025-03-11" codenum="L3685Z2"> <recipelines> <recipeline material="Nepheline Syenite" amount="20.000" tolerance="" unitabbr="GM"/> <recipeline material="New Zealand Kaolin" amount="55.000" tolerance="" unitabbr="GM"/> <recipeline material="Silica" amount="25.000" tolerance="" unitabbr="GM"/> <recipeline material="Zircopax" amount="20.000" unitabbr="GM" added="true"/> </recipelines> </recipe> </recipes>

Born: 2014-11-04, Modified: 2025-03-11 03:08:00

White Cone 04 Engobe for L4170B (3% frit)

|

Code # L3685Z5 |

Batch # -2 |

| Materials | Amt | Units |

|---|---|---|

| Nepheline Syenite | 20.000 | GM |

| New Zealand Kaolin | 55.000 | GM |

| Silica | 25.000 | GM |

| Additions | Units | |

|---|---|---|

| Ferro Frit 3110 | 3.000 | GM |

| Zircopax | 20.000 | GM |

Total:123.00 (R)

Notes

This is based on the L3685Z2 recipe, this adds 3% frit 3110 to increase the firing shrinkage to make L4170B at cone 04/03. We did another test with 5% frit but that increased the maturity too much.

Pictures

L3685Z5 engobe at cone 03 on L4170B

Incredibly white, better than the Amaco Velvet white underglaze.

L3685Z5 is the same as L3685Z2 but it adds 3% Ferro Frit 3110 to get a little more fired hardness. L3685Z8 has 2% Frit 3110.

L3685Z5 engobe fired bars from cone 8 down to 4

L4170B white engobe bowl fired at cone 04

The engobe is L3685Z5. It was applied at the leather hard stage. The bowl was bisque fired and the fish are tissue transfers (not applied very well!).

URLs

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 8 | 94.31 | 83.47 | 36.4 | 36.42 | 8.0 | 5.7% | 11.5% | 0.1% |

| 7 | 94.11 | 83.36 | 35.52 | 35.62 | 7.0 | 5.9% | 11.4% | 0.3% |

| 6 | 94.04 | 83.48 | 32.79 | 36.12 | 6.0 | 6.0% | 11.2% | 10.2% |

| 5 | 94.13 | 83.52 | 35.79 | 36.08 | 5.0 | 5.9% | 11.3% | 0.8% |

| 4 | 94.12 | 83.83 | 37.18 | 37.77 | 4.0 | 5.9% | 10.9% | 1.6% |

LDW - LOI/Density/Water Content

| WWGT | DWGT | H2O | LOI | DENS | |

| 1 | 11.15 | 6.71 | 39.8% |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="White Cone 04 Engobe for L4170B (3% frit)" id="195434" key="Wbv41iZT" date="2025-02-11" codenum="L3685Z5" email="robcartelli@gmail.com"> <recipelines> <recipeline material="Nepheline Syenite" amount="20.000" tolerance="" unitabbr="GM"/> <recipeline material="New Zealand Kaolin" amount="55.000" tolerance="" unitabbr="GM"/> <recipeline material="Silica" amount="25.000" tolerance="" unitabbr="GM"/> <recipeline material="Ferro Frit 3110" amount="3.000" unitabbr="GM" added="true"/> <recipeline material="Zircopax" amount="20.000" unitabbr="GM" added="true"/> </recipelines> </recipe> </recipes>

Born: 2021-03-08, Modified: 2025-02-11 17:09:40

Z3 White Cone 04 Engobe (5% frit)

|

Code # L3685Z3 |

Batch # -2 |

| Materials | Amt | |

|---|---|---|

| Nepheline Syenite | 20.000 | 19.05% |

| New Zealand Kaolin | 55.000 | 52.38% |

| Silica | 25.000 | 23.81% |

| Ferro Frit 3110 | 5.000 | 4.76% |

| Additions | ||

|---|---|---|

| Zircopax | 20.000 | 19.05% |

Total:125.00

Notes

This adds 5% Frit 3110 to the L3685Z2 base recipe (it has not frit). From the data below you can see how much of a difference the 5% makes in the firing shrinkage (compared to Z2). Our philosophy is that engobe and body should have similar firing shrinkages (to prevent flaking on fired ware). The L3685Z5 recipe has 3% frit, that seems to fit L4170B terra cotta the best at cone 04.

The frit is critical to achieve the right firing shrinkage. The frit is potent, a 1 or 2% change has a big effect. Fine-tune the percentage to get the exact fired shrinkage needed.

For mixing instructions see the notes for L3954B.

Pictures

L3685Z3 fired bars from cone 8 down to 06

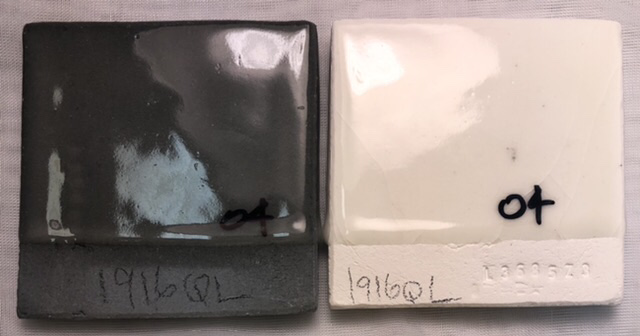

G1916Q crazed after some months on Z3

It did not craze on Z4 black.

G1916QL on L3685Z4, Z3 at cone 04

The L3685Z3 (and Z4) engobes were mixed up as a body for making these glaze test tiles.

After months no crazing on Z4, crazing on Z3.

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 8 | 93.25 | 82.72 | 36.42 | 36.47 | 8.0 | 6.8% | 11.3% | 0.1% |

| 7 | 93.08 | 82.68 | 36.89 | 36.98 | 7.0 | 6.9% | 11.2% | 0.2% |

| 6 | 93.06 | 82.73 | 36.67 | 36.93 | 6.0 | 6.9% | 11.1% | 0.7% |

| 3 | 92.93 | 83.05 | 36.71 | 37.26 | 5.0 | 7.1% | 10.6% | 1.5% |

| 4 | 92.88 | 83.35 | 36.43 | 37.26 | 4.0 | 7.1% | 10.3% | 2.3% |

| 5 | 92.98 | 83.87 | 36.93 | 38.17 | 3.0 | 7.0% | 9.8% | 3.4% |

| 2 | 92.99 | 84.82 | 38.04 | 40.23 | 2.0 | 7.0% | 8.8% | 5.8% |

| 1 | 93.43 | 86.01 | 37.84 | 40.62 | 1.0 | 6.6% | 7.9% | 7.3% |

| 9 | 93.22 | 86.84 | 37.71 | 41.18 | -1.0 | 6.8% | 6.8% | 9.2% |

| 10 | 93.36 | 88.21 | 38.98 | 43.62 | -2.0 | 6.6% | 5.5% | 11.9% |

| 11 | 93.4 | 89.07 | 38.61 | 43.79 | -3.0 | 6.6% | 4.6% | 13.4% |

| 12 | 93.32 | 89.67 | 38.56 | 44.51 | -4.0 | 6.7% | 3.9% | 15.4% |

| 13 | 93.57 | 90.81 | 38.16 | 44.74 | -6.0 | 6.4% | 2.9% | 17.2% |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Z3 White Cone 04 Engobe (5% frit)" id="193010" key="3hqc37Kp" date="2025-02-11" codenum="L3685Z3"> <recipelines> <recipeline material="Nepheline Syenite" amount="20.000" tolerance=""/> <recipeline material="New Zealand Kaolin" amount="55.000" tolerance=""/> <recipeline material="Silica" amount="25.000" tolerance=""/> <recipeline material="Ferro Frit 3110" amount="5.000" tolerance=""/> <recipeline material="Zircopax" amount="20.000" added="true"/> </recipelines> </recipe> </recipes>

Born: 2021-03-08, Modified: 2025-02-11 17:11:42