SIAL Refractory Slip

|

Code # L4575 |

Batch # -2 |

Notes

A very thick slurry having very unusual rheological properties. The water content is only 24.5% so this is heavily deflocculated, likely with sodium silicate. This is low water content might be the product hyper over deflocculation (sodium silicate in kiln mortar can be 30%).

On the other hand, the dry strength is very low, that suggests only enough sodiuim silicate to deflocculate). It also means the clay portion is not plastic. The sieve analysis shows 37% is plus 200 mesh grog. More of the grog will be finer than that also, meaning that the amount of grog could approach 50%.

Our ability to derive the recipe from the oxide composition on the data sheet will be limited since this products contains particulate (that being said, the analysis on the data sheet might be for the clay portion, not including the grog). Our initial guess of the makeup was a mix of ball clay and talc with added kyanite. However after isolating the clay portion (sedimenting the grog in a low specific gravity slurry) and making SHAB test bars from it, the data shows it is almost certain that the clay is almost pure kaolin. The working properties of the clay also confirm that it is kaolin.

Pictures

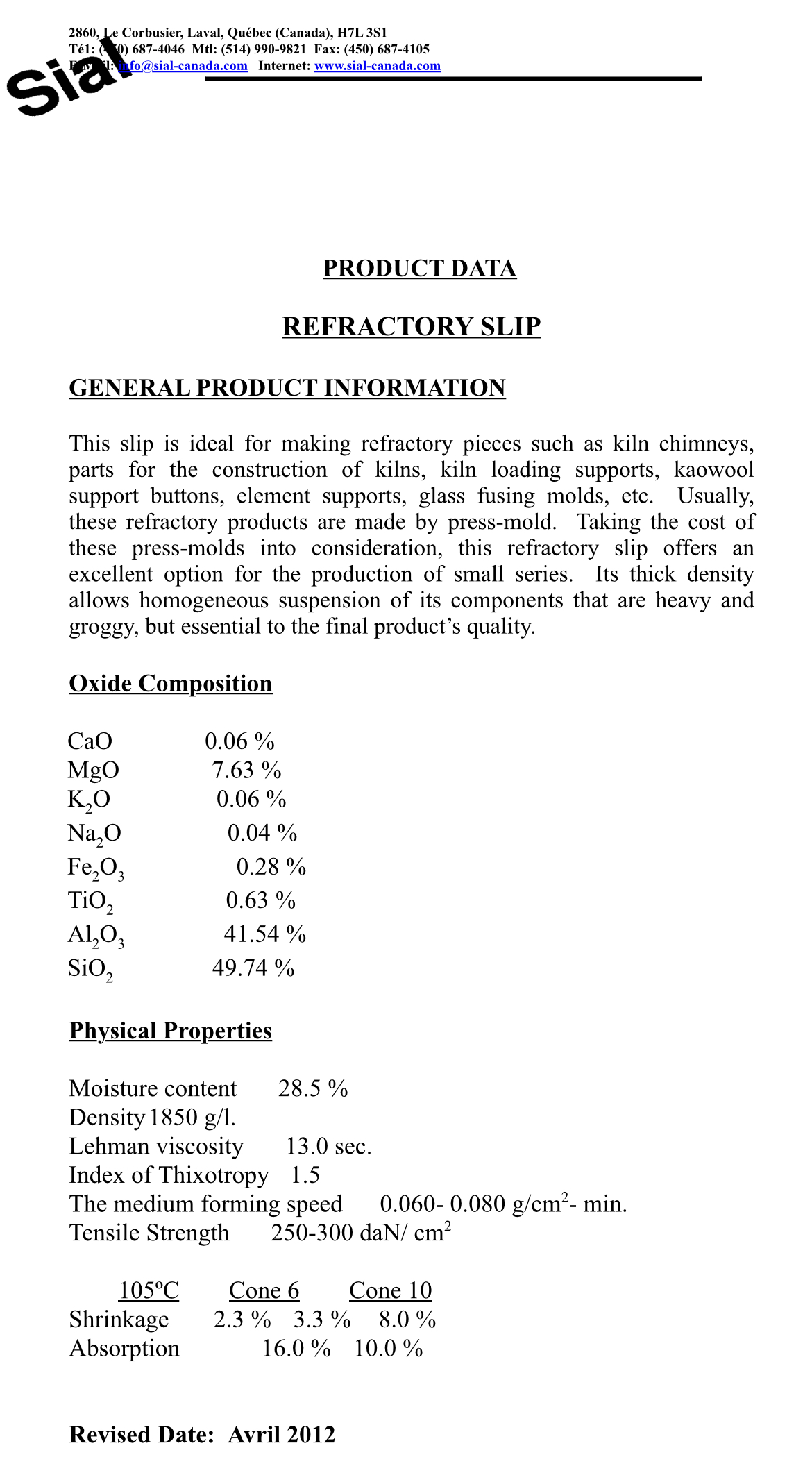

L4575 SIAL refractory slip data sheet

The high Al2O3 indicates this would have to be pure kaolin with possibly some pure calcined alumina added.

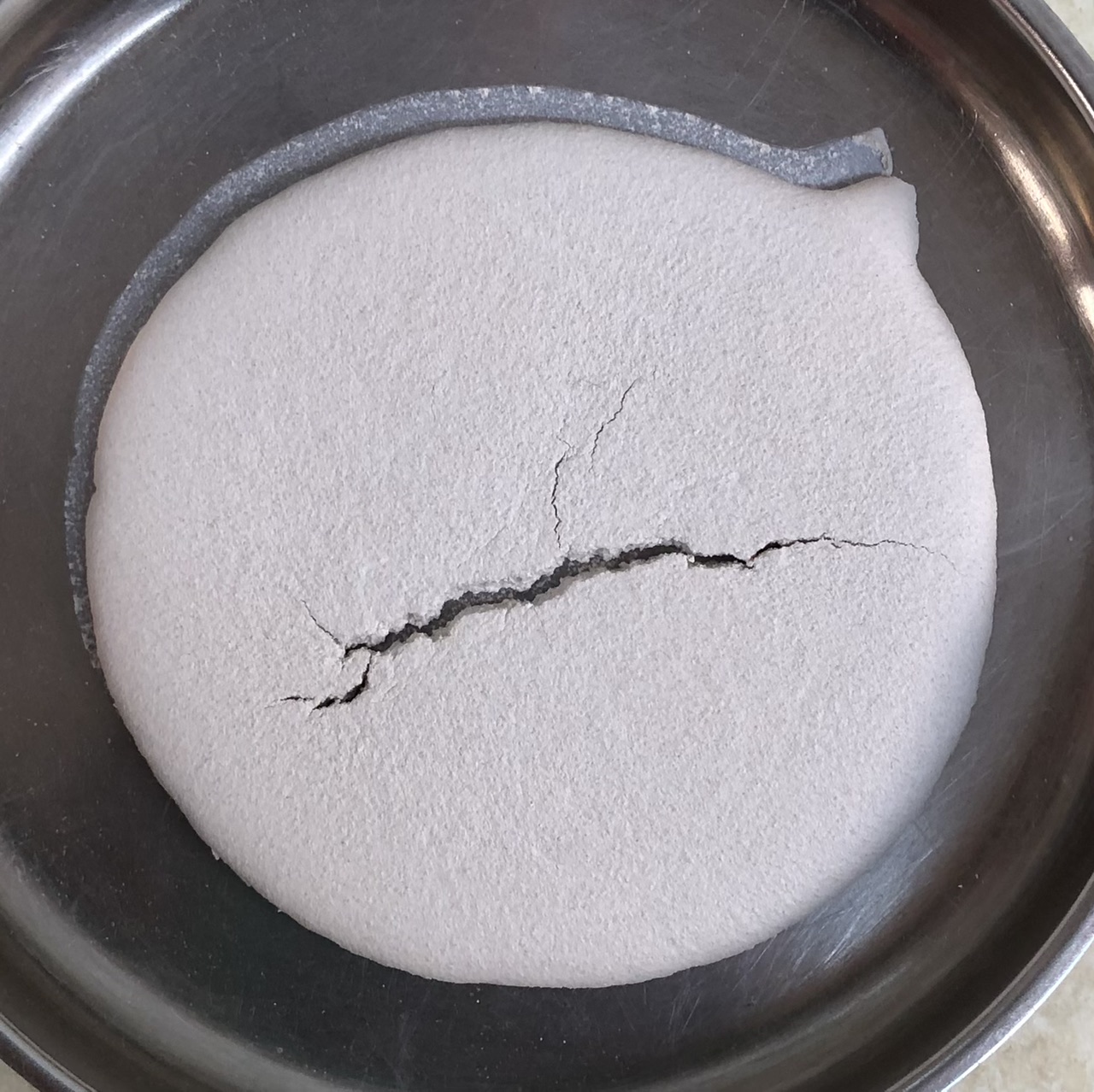

L4575 SIAL Refractory Slip dried

This was dried under a heatlamp. The edge-to-edge shrinkage is almost zero, but the crack in the middle reveals that is going shrink to some extent.

Sieve analysis initial impressions

These are (counterclockwise): 40, 60, 80, 200, 150, 100 mesh sieves. The total initial sample weight was 50 grams, these are likely to add up to at least 30. So the major part of the recipe is a refractory grog having a wide range of particles sizes (50 down to 200 mesh). SIAL makes some grog sizes, this could be one of those (or a mix). Or it could be a grog they get from Plainsman Clays.

Extracting the clay portion

To isolate the clay portion of the mix it was just a matter of adding water and propeller mixing it - the grog settled to the bottom in seconds. The remaining clay slurry behaves and looks like pure kaolin.

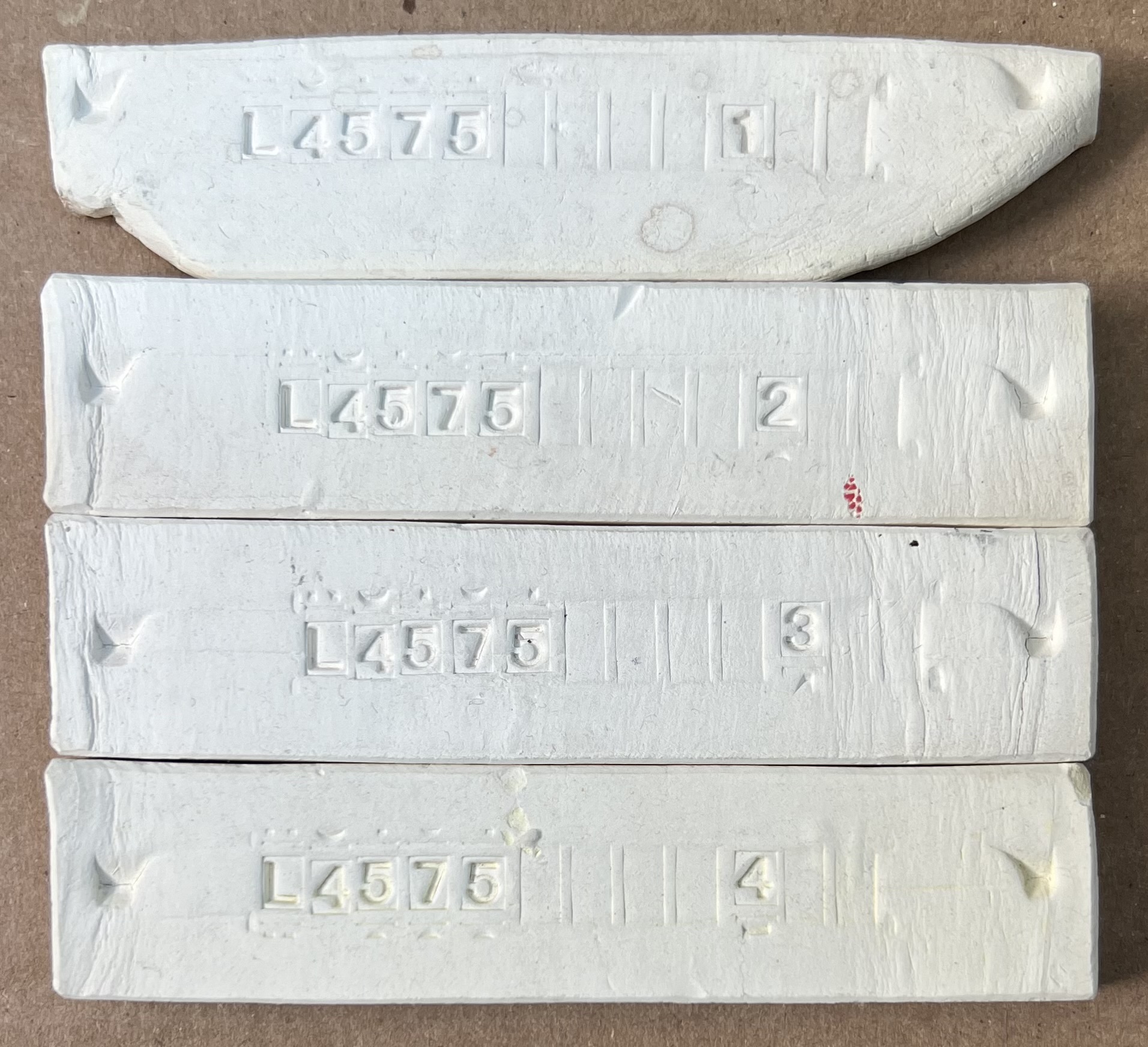

Weighing the oversize on each sieve

Base clay L4575

Appears to be EP Kaolin but numbers indicate it is more refractory. That means they may have added some calcined or hydrated alumina, but not more than 5-10%.

Untitled

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 4 | 96.2 | 86.95 | 32.88 | 35.41 | 10.0 | 3.8% | 9.6% | 7.7% |

| 3 | 96.1 | 87.29 | 33.01 | 36.13 | 8.0 | 3.9% | 9.2% | 9.5% |

| 2 | 96.0 | 87.95 | 32.54 | 36.01 | 6.7 | 4.0% | 8.4% | 10.7% |

| 1 | 95.8 | 88.87 | 28.49 | 32.24 | 6.0 | 4.2% | 7.2% | 13.2% |

SIEV - Sieve Analysis 35-325 Wet

| TOT | 35M | 48M | 65M | 100M | 150M | 200M | |

| 1 | 100 | 0 | 3.22 | 8.76 | 8.64 | 8.3 | 7.82 |

LDW - LOI/Density/Water Content

| WWGT | DWGT | H2O | LOI | DENS | |

| 1 | 16.62 | 12.55 | 24.5% | ||

| 2 | 13.53 | 10.3 | 23.9% |

XML (to paste into Insight)

Born: 2022-12-08, Modified: 2024-03-08 20:13:23

SIAL refractory slip Duplicate

|

Code # L4575A |

Batch # -2 |

| Materials | Amt | |

|---|---|---|

| Pioneer Kaolin | 60.000 | 59.41% |

| *SIAL grog | 40.000 | 39.60% |

| Sodium Silicate | 1.000 | 0.99% |

Total:101.00

Notes

The grade of grog is not specified, it would be necessary to evaluate the grogs they sell and buy the one that approximates the particle size distribution measured in L4575. (it has equal percentages of 200, 150, 100, 65 and about half that of 48 mesh - and likely some minus 200 mesh also).

The amount of sodium silicate is unknown, it needs to be derived by experimentation. The target water content is 25%. That is a very low water content and will be difficult to achieve (perhaps a higher one will need to be tolerated at the start). Likely the sodium silicate and water need to be mixed first and the powder mix slowly added under the agitation of a powerful propeller mixer.

It might be necessary to add the kaolin to the water first, then slowly meter in the grog while mixing. If it is not possible to get all the powder in then increase the sodium silicate percentage and try again.

Pictures

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="SIAL refractory slip Duplicate" id="227257" key="ajwexqcd" date="2023-02-01" codenum="L4575A"> <recipelines> <recipeline material="Pioneer Kaolin" amount="60.000" tolerance=""/> <recipeline material="SIAL grog" amount="40.000" tolerance=""/> <recipeline material="Sodium Silicate" amount="1.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2022-11-06, Modified: 2023-02-01 19:07:03

Kyanite Bisque-Fix, Kiln-Patch

|

Code # L4608 |

Batch # -2 |

Notes

Traditional kiln patching or bisque fixing products are made by mixing kyanite sodium silicate. Commercial products are inexpensive so do not buy an expensive one on Amazon.

48 kyanite is superior for this, its wide range of sizes and the fact that particles expand on firing mean it packs into a dense fired solid when bonded with sodium silicate. Of course, other ceramic materials can be added to get a whiter burning product that is more ceramic in nature. While other grogs could be used, they don't expand like kyanite (that seems to be the key property). Additionally, kyanite particles don't sinter together well, something is needed to bond them (adding others would dilute the sodium silicates's ability to do this so among them a flux would be needed e.g. a frit)

A 30:70 sodium silicate and kyanite mix works best (a 33:66 mix produces a consistency that is a little too flabby and wet and 25:75 is too difficult to mix without special equipment). The kyanite stirs into the sodium silicate quite easily and wets all surfaces rapidly.

The material is not plastic but it does have plenty of cohesion and can be formed and pressed into recesses. It begins to harden on surfaces very quickly (it is thus important to wash tools and containers soon after mixing and wear latex gloves, it can be very difficult to wash off your hands).

The drying and firing shrinkage of this material is remarkable. 0.6% from wet to dry and 0.9% from dry to fired at cone 6!

Containing sodium silicate, this cannot be frozen.

Pictures

A 33:66 sodium silicate:kyanite mix

It is exceptionally easy to stir the kyanite into the sodium silicate, it is ready to form in 10 seconds.

A 30:70 mix produces a less flabby consistency and is still easy enough to mix.

Fired bar of L4608 kiln patch

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 2 | 99.42 | 98.53 | 44.23 | 45.46 | 6.0 | 0.6% | 0.9% | 2.8% |

XML (to paste into Insight)

Born: 2023-02-10, Modified: 2025-03-21 13:46:00