Oringal Alberta Slip Amber/Honey base

|

Code # GA6-A |

Batch # -2 |

| Materials | Amt |

|---|---|

| Alberta Slip 1000F Roasted | 40.000 |

| Alberta Slip | 40.000 |

| Ferro Frit 3134 | 20.000 |

Total:100.00

Auto Unity Formula

|

Si:Al: 7.0:1 7.6 (Molar:7.2) 4.9 |

Notes

Don't use this glaze anymore as a transparent honey, use GA6-B instead (it produces a better glass and is more durable by virtue of higher Al2O3 and SiO2 content).

The was a long-time cone 6 base recipe for Alberta Slip. For this and the GA6-B we recommend a 2% iron oxide addition to get a richer color. Fusion Frit F-12 has proven a good substitute for 3134.

This version is still needed for a couple of reasons:

1. This one produces rutile blues in the cool-and-soak C6DHSC firing schedule (likely because this has a lower Al2O3 level, enabling the crystallization of the TiO2 in the rutile).

2. This is also the only version that crystallizes in slow cool firings (e.g. the C6DHSC schedule).

Pictures

GA6A Alberta Slip base using Frit 3124, 3249 and 3195

The body is dark brown burning Plainsman M390 (cone 6). The amber colored glaze is 80% Alberta Slip (raw:calcine mix) with 20% of each frit. The white engobe on the inside of two of the mugs is L3954A (those mugs are glazed inside using transparent G2926B). The Alberta Slip amber gloss glaze produces an ultra-gloss surface of high quality on mugs 2 and 3 (Frit 3249 and 3195). On the outside we see it this glaze on the white slip until midway down, then on the bare red clay. The amber glaze on the first mug (with Frit 3124) has a pebbly surface that is not working nearly as well. These mugs are fired using a drop-and-soak firing schedule.

GA6-A Alberta Slip Base with tin to prevent crystallization

Left: L3820 (casting M390) with Ravenscrag Floating blue outside and Alberta Slip GA6-A inside. That inside glaze has 1% added tin, it prevents the crystals that that normally grow when this is slow cooled using the C6DHSC firing schedule (like the inside glaze on the right). These crystals can be very beautiful on decorative surfaces, but if you want a clear amber glass they are not good.

Right: M390 red-burning cone 6 stoneware (P6281) with Alberta Slip Rutile blue glaze outside and GA6-A liner (the slow cooling having crystallized it).

Crystallization can also be prevented by using frit 3195 or 3249 instead, they fire clear in fast or slow firings.

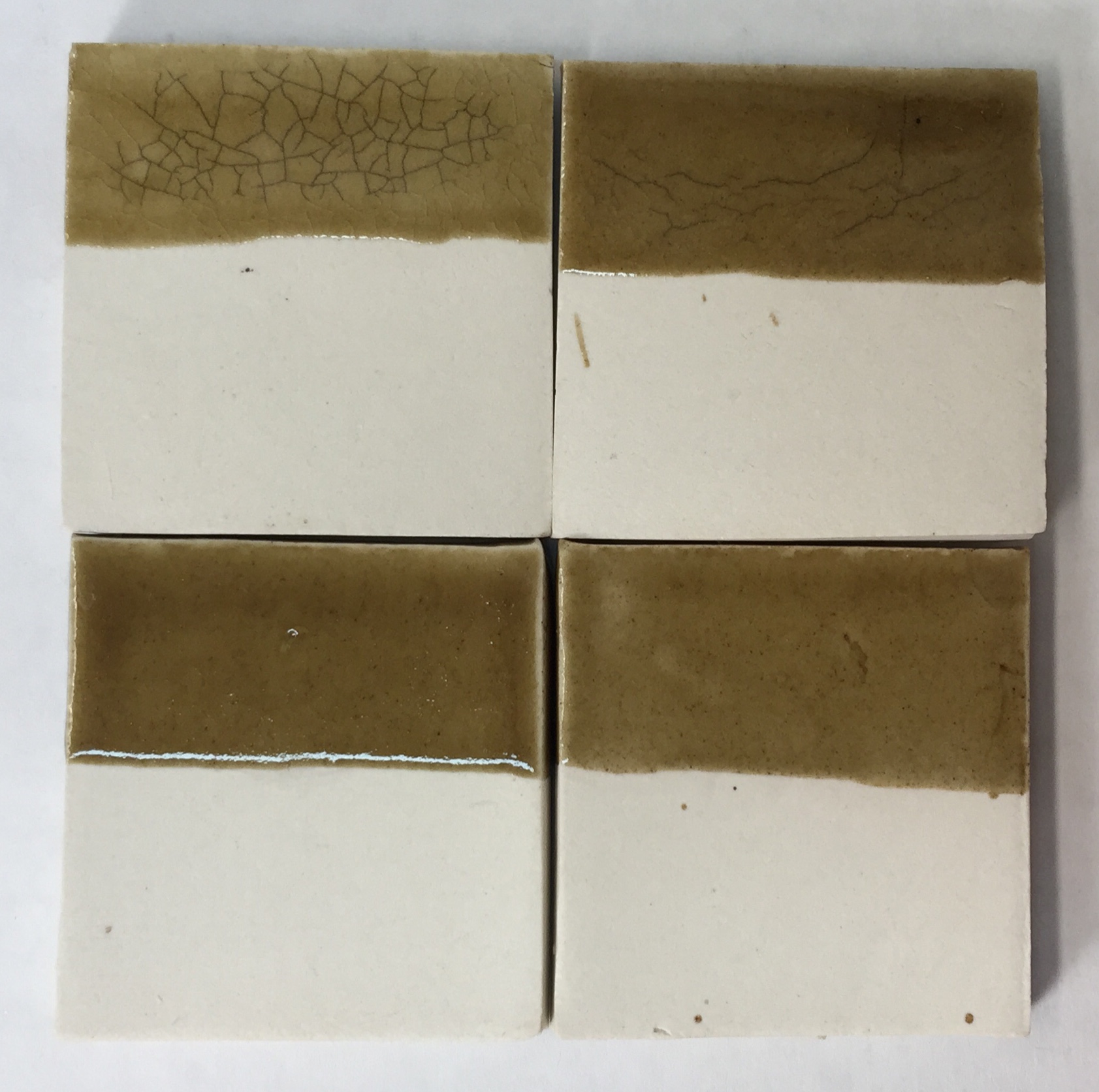

GA6-A Alberta Slip base crazes on P300

Fired in a cool-and-soak firing. It is better to use GA6-B (which employ Frit 3195 instead of Frit 3134).

Melted glaze for thermal expansion test has bubbled

GA6-A glaze with four frits (flow tests)

Four frits in GA6-A at cone 6

Frit 3195 (top left), 3134 (top right)

3214 (bottom left), 3249.

10 gram melt balls.

Alberta Slip on P300 with Frits 3134, 3124, 3249, 3195

This porcelain can be difficult to fit glazes to because it has a lower-than-normal silica content. Each of these test samples was thermal shock tested: 300F to ice water.

Frit 3134 version (top left) crazing.

3124 slight crazing (top right).

3249 and 3195 (bottom) are uncrazed.

3134 version has the cleanest surface but 3195 is close behind.

These were not slow cooled or drop-soaked during firing so they are all transparent.

Typecodes

ST-Untitled typecode

Alternate Code Number:GA6-A

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Oringal Alberta Slip Amber/Honey base" id="70758" key="g8nm2wNw" date="2023-09-16" typecodes="ST" codenum="GA6-A" picturebasename=""> <recipelines> <recipeline material="Alberta Slip 1000F Roasted" amount="40.000" tolerance=""/> <recipeline material="Alberta Slip" amount="40.000" tolerance=""/> <recipeline material="Ferro Frit 3134" amount="20.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2007-03-09, Modified: 2023-09-16 16:22:37

Alberta Slip Original cone 6 base glaze

|

Code # L3500 |

Batch # -2 |

| Materials | Amt |

|---|---|

| Alberta Slip 1000F Roasted | 40.000 |

| Alberta Slip | 40.000 |

| Ferro Frit 3195 | 20.000 |

| Additions | |

|---|---|

| Red Iron Oxide | 2.000 |

Total:102.00

Auto Unity Formula

|

Si:Al: 6.1:1 7.3 (Molar:6.8) 5.0 Cost 0.08 per kg |

Notes

Alta known as GA6-B at PlainsmanClays.com.

The successor recipe to GA6-A (this uses Ferro Frit 3195 or the equivalent Fusion F-2 instead of 3134). It fires to a more brilliant glossy and durable surface and has become the standard go-to honey/amber base recipe for Alberta Slip at cone 5 or cone 6. We recommend the C6DHSC or C5DHSC firing schedules.

We recommend the addition of 2% iron oxide to get a richer color. The iron has an added benefit: It gels the glaze (the 2% is low enough that it does not over-gel, it just produces a nicer-to-use slurry, one that goes on more evenly).

This recipe fires to a lower thermal expansion than GA6-A did (by virtue of higher B2O3, Al2O3 and SiO2 levels) so will solve any crazing issues you may have had. For an even lower expansion and better melting version consider using L3500G, it is made using Ferro Frit 3249.

This base will not produce floating blue effects with rutile or titanium additions, the GA6-A base is needed for that. In addition, this one also does not crystallize on slow cooling the way GA6-A does.

If you need even better durability, this will likely accept 45 micron silica additions without loss of gloss, especially at cone 6. Start by adding 5% (then 10%). The more it will take the harder it will be.

Batch Ticket Notes

Joe: Sept./2023

Alta. Slip ratio at 50/50 raw to roasted.

powder to water ratio 100/88

S.G. 1.48

Yield on 5 Kg. of powder is 6.5 litres of glaze.

Screened 80 mesh and retained 11.04 grams on screen. This was 60 mesh Alberta Slip P7087.

Joe: April 4/24 Mixed up exact same recipe as above Sept./2023 with exactly same result, 9.5 grams retained on 80 mesh screen.

On April 16, after Tony used the glaze a few times, he added 200ml. of water which would be equivalent of 200 grams and he felt the glaze was going on the right thickness whereas before it applied slightly thick.

So, this would be a powder to water ratio of 100/92

In Sept./24 this glaze used again and specific gravity adjusted to 1.466 and this is about right, as a liner glaze there was barely any cracking and only occured at the point where inside wall of mug meets bottom and was barely visible. A noticeable difference from the 1.48 S.G. original reading when used as a liner glaze when first made.

Pictures

GA6-A base using Frit 3249 and 3195 on buff body

The body is buff-burning Plainsman M340 (cone 6). The amber-colored glaze is 80% Alberta Slip (raw:calcine mix) with 20% of each frit. The inside of mug 1 is white engobed (L3954A) and with transparent over it (G2926B).

The GA6-B glaze uses Frit 3195, covering mug 2 completely. Mug 1 uses low expansion frit 3249, it fires to the same brilliant gloss. But its low expansion could cause shivering on certain bodies.

These mugs are fired using a drop-and-soak firing schedule yet no micro-crystals have grown as they would using the GA6-A recipe with Frit 3134.

GA6-B Alberta Slip base glaze does not crystallize

Right: The traditional Alberta Slip amber transparent has 80% Alberta Slip and 20% Ferro Frit 3134. It forms micro-crystals if the kiln is not cooled quickly. The Frit 3195 version on the left retains its brilliant transparent nature. The reason is the higher levels of Al2O3 (Frit 3134 has almost zero Al2O3).

M390 clay with white engobe inside

L3954A engobe inside, clear glazed inside (G2926B). Outside is GA6B base (uses Frit 3195 instead of 3134). The result is a glossier more defect free glass.

P300 with AlbertaSlip:Frit 3195 glaze fires crystal-free

This glaze produces a flawless results with a normal free-fall cool cycle. But that is not what this was. In this cone 6 firing the temperature was dropped from 2200F to 2100F, held for 30 minutes, then dropped slowly (300F/hr) all the way down to 1400F. In that firing schedule the standard GA6-A base recipe would be completely covered in iron silicate crystals.

M340 with L3954B engobe, GA6-B base glaze. Cone 6.

GA6-B base Alberta Slip glaze on M340. Cone 6.

No iron oxide added.

GA6-B plus iron oxide

Top: GA6-B

Bottom: Plus 1, 2, 3 and 4% iron oxide.

Alberta Slip as a Celadon at cone 6 and 10R

Left: Alberta Slip 80, Frit 3195 20. On Plainsman M370.

Right: Alberta Slip/Ravenscrag Slip 50:50 mix. On Plainsman P700.

GA6-B Base does not make rutile blue

Left is the standard GA6-A with Frit 3134. GA6-B on the right has the rutile also, and was in the same firing, but the higher Al2O3 prevents its variegating action.

G3903, L3500G, GA6-B on Coffee Clay (insides)

C6DHSC firing

Typecodes

ST-Untitled typecode

Alternate Code Number:GA6-B

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Alberta Slip Original cone 6 base glaze" id="143991" key="pzAq2FSs" date="2024-11-23" typecodes="ST" codenum="L3500" picturebasename=""> <recipelines> <recipeline material="Alberta Slip 1000F Roasted" amount="40.000" tolerance=""/> <recipeline material="Alberta Slip" amount="40.000" tolerance=""/> <recipeline material="Ferro Frit 3195" amount="20.000" tolerance=""/> <recipeline material="Red Iron Oxide" amount="2.000" added="true"/> </recipelines> </recipe> </recipes>

Born: 2007-03-09, Modified: 2024-11-23 00:02:28

Alberta Slip + Frit 3249

|

Code # L3500G |

Batch # -2 |

| Materials | Amt |

|---|---|

| Alberta Slip 1000F Roasted | 40.000 |

| Alberta Slip | 40.000 |

| Ferro Frit 3249 | 20.000 |

| Additions | |

|---|---|

| Red Iron Oxide | 2.000 |

Total:102.00

Auto Unity Formula

|

Si:Al: 5.9:1 6.7 (Molar:6.0) 5.0 Cost 0.08 per kg |

Notes

This is part of a program to compare the results of fluxing Alberta Slip for cone 6 using 4 different frits (3134, 3124, 3195 and 3249).

Frit 3249, used here, is a low expansion frit, it reduces the thermal expansion of the Alberta Slip base GA6-A (from 7.6 to 6.5). This is the version to use if any of the others craze.

Even though this recipe calculates to a low Si:Al ratio and a very high MgO level (both indicative of a matte glaze), it fires ultra-glossy.

Since Alberta Slip is not as high in iron oxide as the original Albany Slip, the added red iron oxide makes the color richer (on iron bodies it fires almost black).

If durability is very important for you, this melts well enough that it will accept additions of silica (we recommend 45 micron grade). The more it will take yet still melt to an ultra-gloss, the harder and more durable it will be. Start by adding 10%.

This base will not produce floating blue effects with rutile or titanium additions, the GA6-A base is needed for that.

Pictures

P6851 M332 with L3500G AltaSlip 3249 base inside

P6823 M350 with L3500G AltaSlip 3249 base inside

GA6-C outside, slow cool firing.

L4115J3S cone 6 - L3500G Alberta Slip glaze

L4115J3S is a Plainsman 3D-based speckled stoneware. It is vitreous and very functional.

The L3500G recipe adds 20% Ferro Frit 3249 to Alberta Slip to produce a honey glaze at cone 6 (we have added 2% iron to darken it).

Inside glazes:

Left mug: G2934W white matte.

Right mug: G2926S, a lower thermal expansion version of G2926B, with 10% added zircopax.

L3500G with Frit 3249, F69

Identical. The F69 may have slight smoother surface.

G3903, L3500G, GA6-B on Coffee Clay (insides)

C6DHSC firing

Typecodes

ST-Untitled typecode

Alternate Code Number:GA6-A

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Alberta Slip + Frit 3249" id="193133" key="KScSAysm" date="2023-09-16" typecodes="ST" codenum="L3500G" picturebasename=""> <recipelines> <recipeline material="Alberta Slip 1000F Roasted" amount="40.000" tolerance=""/> <recipeline material="Alberta Slip" amount="40.000" tolerance=""/> <recipeline material="Ferro Frit 3249" amount="20.000" tolerance=""/> <recipeline material="Red Iron Oxide " amount="2.000" added="true"/> </recipelines> </recipe> </recipes>

Born: 2007-03-09, Modified: 2023-09-16 16:20:54

Alberta Slip + Frit 3249 and Silica

|

Code # L3500H |

Batch # -2 |

| Materials | Amt | |

|---|---|---|

| Alberta Slip 1000F Roasted | 40.000 | 36.36% |

| Alberta Slip | 40.000 | 36.36% |

| Ferro Frit 3249 | 20.000 | 18.18% |

| Silica (45 micron silica) | 10.000 | 9.09% |

| Additions | ||

|---|---|---|

| Red Iron Oxide | 2.000 | 1.82% |

Total:112.00

Auto Unity Formula

|

Si:Al: 7.0:1 6.4 (Molar:5.8) 4.5 Cost 0.07 per kg |

Notes

Could this to make a more durable surface. The Frit 3249 version melts the best and the more silica it will take, yet still melt well, the harder and more durable the surface should be be. That being said, the surface is not as smooth as expected, this is too much silica.

Added 40g silica to 357g of glaze (715g wet).

Pictures

L3500H drop-and-soak firing, appears to need slow cool

L3500H cone 6 slow cool is much more glassy

This is the C6DHSC schedule.

L3500H on the insides of a buff and dark stoneware

Although well melted at cone 5, it is not glassy smooth as normal with the C5DHSC firing schedule.

L3500G and L3500H melt fluidity test to cone 6

The extra 10% silica has this effect on the melt flow. Typical functional glazes would be similar to the H (e.g. G2926B or G2934).

Typecodes

ST-Untitled typecode

Alternate Code Number:GA6-A

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Alberta Slip + Frit 3249 and Silica" id="213844" key="1eSJFmx9" date="2023-03-06" typecodes="ST" codenum="L3500H" picturebasename=""> <recipelines> <recipeline material="Alberta Slip 1000F Roasted" amount="40.000" tolerance=""/> <recipeline material="Alberta Slip" amount="40.000" tolerance=""/> <recipeline material="Ferro Frit 3249" amount="20.000" tolerance=""/> <recipeline material="Silica" lookup="45 micron silica" amount="10.000" tolerance=""/> <recipeline material="Red Iron Oxide " amount="2.000" added="true"/> </recipelines> </recipe> </recipes>

Born: 2007-03-09, Modified: 2023-03-06 14:30:12

Alberta Slip + Frit FZ-16

|

Code # G3903 |

Batch # -2 |

| Materials | Amt |

|---|---|

| Alberta Slip 1000F Roasted | 40.000 |

| Alberta Slip | 40.000 |

| Fusion Frit FZ16 | 20.000 |

Total:100.00

Auto Unity Formula

|

Si:Al: 7.1:1 7.4 (Molar:6.9) 4.9 |

Notes

This version of the Alberta Slip base honey glaze melts the best. It works well down to cone 4. It produces an incredibly glossy surface (pieces will slide out of your hands easily if you do not hang on to them firmly, tiles cannot be stacked because they will slide off each other).

Fusion Frit FZ-16 is not easy to obtain and it is expensive. But you get what you pay for! We know of no other way to make a glossy glaze with as smooth a surface as this one has.

Pictures

GA6-A vs G3903 using FZ-16 frit at cone 6

Incredible result. Super fluid. No dimples or bubbles compared to the GA6-B on the left.

The L3903 is mislabelled, should be G3903.

G3903 on P300, M340, M390

Fantastic result. Super glossy. These tiles are very slippery, cannot stack them on top of each other!

G3903, L3500G, GA6-B on Coffee Clay (insides)

C6DHSC firing

G3903 the super glossy at cone 4

This is among the glossiest surfaces we have seen. This inside surface of this bowl is so slippery that contents will slide out unless proper care is taken!

P6954 M325 with G3903 outside at cone 4 DS firing

Insides:

G3936 zero frit transparent - Needs to be thicker

G2936 Ravenscrag:3249 80:20: Nice surface but not as glossy as it appears on the photo

G2926SX: Silky surface, needs a little more heat.

P6954, L4483B, G3903, G2917, G3936 Cone 5 SC

The glossy transparent Glaze might not be ideal for slow cool.

Typecodes

ST-Untitled typecode

Alternate Code Number:GA6-A

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Alberta Slip + Frit FZ-16" id="180298" key="xXLNHDP9" date="2021-12-13" typecodes="ST" codenum="G3903" picturebasename=""> <recipelines> <recipeline material="Alberta Slip 1000F Roasted" amount="40.000" tolerance=""/> <recipeline material="Alberta Slip" amount="40.000" tolerance=""/> <recipeline material="Fusion Frit FZ16" amount="20.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2007-03-09, Modified: 2021-12-13 15:46:03