Cone 05+ Expansion Adjustable Gloss Base

|

Code # G1916Q |

Batch # -2 |

| Materials | Amt |

|---|---|

| Ferro Frit 3195 | 65.000 |

| Ferro Frit 3110 | 10.000 |

| Ferro Frit 3249 | 10.000 |

| No. 5 Ball Clay | 15.000 |

Total:100.00

|

Si:Al: 6.3:1 6.8 (Molar:6.8) 1.4 |

Notes

Although similar to the previous G1916M, this recipe provides greater thermal expansion adjustability. It combines a middle-of-the-road thermal expansion frit with a very low and very high expansion frit (they cancel each other out but increase gloss of the otherwise silky Frit 3195). The frits in this recipe (or similar ones) are common. We adjusted this in a later version, G1916QL1, it employs a kaolin for better clarity and more frit 3249 for glaze fit on more bodies.

If you can't get Frit 3249: Try 3195 by itself. If it shivers, add frit 3134 until it passes stress testing. If it crazes, use Frit 3124 as the base and add a little talc.

As is, this melts well from cone 05 and is stable to cone 2 or higher.

Do not assume the glaze fits because a piece emerges from the kiln without crazing or shivering. Thermally stress it (e.g. ICWT test).

If this crazes, try 65:20:15 (3195:3249:EPK).

If it shivers, use 65:20:15 (3195:3110:EPK).

If the problem persists reduce the 3195 and increase the other (e.g. 55:30:15).

The ball clay also imparts good working properties and it has a lower LOI than EPK (to generate less micro-bubbles in the glaze).

Add 2% iron oxide to this when using on terra cotta bodies to enhance their red, the iron particles also act as a fining agent to remove the microbubbles they produce.

Because this employs ball clay, it the glass will have a slightly amber color (from the Fe2O3 in the clay). If that is an issue, try using a kaolin instead (we recommend New Zealand or Grolleg, the G1916Q2 and G1916Q3 variations do this).

Although drop-and-soak firing schedule helps clarity of transparent glazes at higher temperatures this glaze can produce crystal clear results with fast firing.

We find that 3800 water for 4000 powder produces ~1.44SG. The slurry gels more than with EPK, Grolleg or NZK.

Pictures

G1916Q at Cone 01 on 3D+iron

Very nice results on L3724E red body at cone 01. Piece is very strong.

1916J and Q fired to 1450F

These glazes are starting to melt, the surface having reached the consistency of a porcelain and have densitfied to very low porosity. Notice the iron in the ball clay really shows up at this stage (it will be less evident later).

G1916Q Cone 04 using 04DSSC schedule

Counterclockwise: L212, Raku, Buffstone, L213, L210, L215

Crazing out-of-the-kiln on Raku and buffstone.

Bisque 04-03.

G1916Q and J fired 1650-2000F

Ten-gram balls melted and flattened as they fired. They soften over a wide range, starting well below cone 010! At 1650F carbon material is still visible (even though the glaze has lost 2% of its weight to this point), it is likely the source of the micro-bubbles that completely opacify the matrix even at 1950F (cone 04). This is an 85% fritted glaze, yet it still has carbon; think of what a raw glaze might have! Of course, this is a thick layer, so the bubbles are expected. But they still can be an issue on a piece of ware. So to get the most transparent possible result it is wise to fire tests to find the point where the glaze starts to soften (1450F in this case), then soak the kiln just below that (on the way up) to fire away as much of the carbon as possible.

Success with cyrstal clear glaze cone 03

Uses Cone 03 soak-soak-slow cool schedule.

Left: P6282 with 3685U slip and 1916Q. Clear and very good. Glaze is thicker than the other two. Shivering on lip, the slip is not fitting the body.

Center: P6282 with G2931F Ulexite clear. Better clarity even though it is applied very thin. Shivering on lip, the slip is not fitting the body.

Right: L3724F with 3685U slip. No shivering. Very good coverage of the glaze, very clear, the best I have seen yet!

G1916Q on L215, L212, L210, L213, Buffstone at cone 03

All exited from the klin without crazing. The L215, L213, L210 and L212 samples subsequently survived a 300F/Icewater test without crazing, but the Buffstone did not. The L213 would not likely survive a cold-to-hot test without shivering.

1916Q cone 04, 03

Both were slow cooled. While the cone 04 version is glassy and ultra-gloss, it has significant clouding of micro-bubbles. The cone 03 version, right, is completely transparent.

G1916Q on L210 fired at cone 04

Has survived for a year without crazing.

G1916Q+2%Iron on L212 talc body fired at cone 05

This will likely shiver over time. But the speckle that happens on white bodies is clearly visible.

G1916Q applied thickly on L215 fired cone 04

No crazing after 2 months.

G1916Q on L4170 cone 04

Thin application is clearly the way to get the best transparent. The glaze eventually craze where application is thicker.

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Cone 05+ Expansion Adjustable Gloss Base" id="56565" key="wkrYLxfe" date="2025-04-06" codenum="G1916Q"> <recipelines> <recipeline material="Ferro Frit 3195" amount="65.000" tolerance=""/> <recipeline material="Ferro Frit 3110" amount="10.000" tolerance=""/> <recipeline material="Ferro Frit 3249" amount="10.000" tolerance=""/> <recipeline material="No. 5 Ball Clay" amount="15.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2014-03-04, Modified: 2025-04-06 20:39:52

Cone 05+ Lower Expansion glaze

|

Code # G1916QL1 |

Batch # -2 |

| Materials | Amt |

|---|---|

| Ferro Frit 3195 | 60.000 |

| Ferro Frit 3249 | 25.000 |

| New Zealand or Grolleg kaolin (Grolleg Kaolin) | 10.000 |

| 45 micron Silica (Silica) | 5.000 |

Total:100.00

Auto Unity Formula

|

Si:Al: 5.9:1 6.0 (Molar:6.0) 1.2 |

Notes

This is a much-lower-thermal-expansion version of our standard G1916Q low fire clear recipe (which was delay-crazing on the L4410C, L4410K, L4410L cone 04 test bodies). The lower expansion was achieved by eliminating all high-expansion 3110 and more than doubling the low-expansion 3249. This now shivers on our L4170B terra cotta (use the G1916Q for it).

This also switches the ball clay for New Zealand or Grolleg kaolin, removed the amber coloration from the glass. And this is melting better (since frit 3249 is a very active flux), that means it is very practical at cone 05.

The lower surface tension of this also makes it a better candidate than G3879 for opacification with zircon.

We did initial mixes using both Grolleg and New Zealand kaolins. The slurry rheologies were the same. Sieving to at least 80 mesh or blender mixing is required to break down these kaolins (they are very sticky and form agglomerates).

The initial mixes for a dipping glaze were 1500g powder, 1200g water producing a specific gravity of 1.49 and yielding just over 1.80 litres.

The down side of this recipe is settling (after a few weeks). And it is going on too thick on bisque, even on a quick dip. Leaving the recipe as is at least some CMC gum is needed for water retention Increasing the water to 50% (thus a 1:1 mix of water:powder) and adding 0.5% Veegum improved the slurry without causing and dripping or excessively slow drying. That being said, it is still settling more than desired. If the cleanest possible transparent is not the priority the G1916QL recipe is easier to get a good slurry.

Conversely, this recipe is working well for brushing glazes. We make 1 pint using 340g powder, 440g water, 5g CMC gum and 5g of Veegum. On aging we add more CMC if needed (by blender mixing). Even when it dries out to 50:50 water:powder it still paints well.

Pictures

G3879C, G1916Q, G1916QL1 on L213 Cone 04

The move from ball clay to New Zealand kaolin (centre mug vs right mug) greatly improves the clarity (because of the reduction in iron and titanium).

Cone 04 G1916QL1 vs G3879C melt flow comparison

G1916QL1 is more melt fluid so it is likely useful before cone 04. But G3879C is also very fluid (it also has a higher surface tension). Both are producing textbook high quality flows.

Spectrum 705 Black, G1916QL clear on L4410K at cone 03

The quality of this piece is amazing! The evenness of coverage that can be achieved with brush-on glazes is impressive. This was my favourite coffee mug. However it did finally craze after about 2 weeks of use (that motivated the recipe change to G1916QL1).

G3879C, G1916QL1 on L4410L Bisque 1800 glaze cone 04

No crazing after weeks of use, ultragloss.

Frit 524 has much less iron, that is why that mug is so much whiter.

After several months at home the G3879C did craze.

G1916QL1. G3879C, G3879G1 on L213 tiles - Cone 04

These are all craze-free after several months.

G1916QL1 on medium temperature porcelains

Clockwise from top left: L213, M370, P300, Polar Ice

After a month none of these have crazed. After several months the P300 crazed.

At cone 03 the glaze is more transparent and brilliant than with anything possible at cone 6.

At cone 04 and 05 the porcelains eventually do craze.

Cost comparison vs. Spectrum 700 Clear

G1916QL1 on L215 - more than a year old

This was done as a brushing version of this recipe.

Not crazing, not shivering.

Refired a year later, clouding reduced slightly.

Testdata

LDW - LOI/Density/Water Content

| WWGT | DWGT | H2O | LOI | DENS | |

| 1 | 16.55 | 9.52 | 42.5% | ||

| 2 | 11.67 | 5.94 | 49.1% | ||

| 3 | 5.04 | 2.43 | 51.8% |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Cone 05+ Lower Expansion glaze" id="202545" key="Yh3Zy6PC" date="2024-03-29" codenum="G1916QL1"> <recipelines> <recipeline material="Ferro Frit 3195" amount="60.000" tolerance=""/> <recipeline material="Ferro Frit 3249" amount="25.000" tolerance=""/> <recipeline material="New Zealand or Grolleg kaolin" lookup="Grolleg Kaolin" amount="10.000" tolerance=""/> <recipeline material="45 micron Silica" lookup="Silica" amount="5.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2014-03-04, Modified: 2024-03-29 18:06:15

Cone 05+ Low Expansion Transparent glaze

|

Code # G1916QL |

Batch # -2 |

| Materials | Amt |

|---|---|

| Ferro Frit 3195 | 65.000 |

| Ferro Frit 3249 | 20.000 |

| No. 5 Ball Clay | 15.000 |

Total:100.00

Auto Unity Formula

|

Si:Al: 5.6:1 6.1 (Molar:6.2) 1.4 |

Notes

This is a lower-thermal-expansion version of our standard G1916Q low fire clear recipe (which was delay-crazing on the L4410C at cone 04 clay). The 15% ball clay impart good slurry properties (to enable getting it on evenly if a thixotropic consistency can be achieved).

The original recipe was 65:10:10 of Frit 3195:3110:3249. This one trades all the high-expansion 3110 for low expansion 3249. Fitting this to the L4410C body is a matter of testing from cone 04 and up until a temperature is reached where the glaze does not craze. This even shivers on our L4170B terra cotta, so the thermal expansion is certainly plenty low enough for most uses.

This is melting well and producing dazzling ultra clear results! One reason that it melts so well might be that the recipe contains no silica (enough SiO2 is supplied by the other materials).

Equal parts of water/powder seem to create a pleasant slurry that does not settle.

Pictures

G1916QL on L3685Z2 on L4170B at Cone 04, 02

After months both are still uncrazed. But some shivering on the rim of cone 02 piece.

L4410K with G3879G1 and G1916QL at cone 04

Both are crystal clear, results are stunning! Both the G3879G1 and G1916QL glazes held up well in my kitchen at home. For a while. The G1916QL on crazed after a couple of weeks. The G1 crazed after about a month.

Spectrum 705 Black, G1916QL clear on L4410K at cone 03

The quality of this piece is amazing! The evenness of coverage that can be achieved with brush-on glazes is impressive. This was my favourite coffee mug. However it did finally craze after about 2 weeks of use (that motivated the recipe change to G1916QL1).

G3879C vs. G1916QL on L4410K low fire white

The iron from the ball clay is the reason the glaze on the right is off-white.

G1916QL on L4410J - 2 months, no crazing, brilliant surface

L4410L with G1916Q, G1916QL and G3879 - Cone 04

Only the G1916Q is crazing after several months.

The L4410L body is 50:30:20 Ball clay, Nepheline, Dolomite.

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Cone 05+ Low Expansion Transparent glaze" id="192370" key="sEL4N5PL" date="2024-03-25" codenum="G1916QL"> <recipelines> <recipeline material="Ferro Frit 3195" amount="65.000" tolerance=""/> <recipeline material="Ferro Frit 3249" amount="20.000" tolerance=""/> <recipeline material="No. 5 Ball Clay" amount="15.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2014-03-04, Modified: 2024-03-25 23:56:45

Cone 04+ UltraClear Glossy Base

|

Code # G3879 |

Batch # -2 |

| Materials | Amt | |

|---|---|---|

| Fusion Frit F-524 | 850.000 | 82.93% |

| Fusion Frit F-69 | 40.000 | 3.90% |

| EPK | 90.000 | 8.78% |

| Silica | 45.000 | 4.39% |

Total:1,025.00

Auto Unity Formula

|

Si:Al: 8.4:1 6.5 (Molar:6.1) 1.3 Cost 3.19 per kg |

Notes

We developed this for cone 06-04 to fit many clay bodies (without crazing), melt well at cone 05 and produce a more transparent glaze (rather than the amber of G2931K and G1916Q). The frit F-524 in this recipe is uncommon among potters but common in industry, it is high quality. We later adjusted this recipe to produce variations (e.g. with whiter kaolin, more of the frit F-69 to get a lower thermal expansion).

We found the inspiration for this on testing many commercial clears and finding one that stood above the others regarding fit and clarity at 04 (we had it analyzed and reverse-engineered it using the materials we have). Frit F-524 is expensive, but this glaze is heads-above a number of commercial clear glazes we have tested (they are not ultra-clear, they pinhole or blister or craze, they are not glossy enough, they do not have dipping versions, they are not adjustable). The F-69 is also expensive, but it enables fitting this to any body.

Additions of tin and zircon produce a white that melts just as well as the clear. To make bright-colored glazes this should be an excellent base (remember, this is the clear glaze recipe currently used by at least one commercial supplier of bright-colored glazes). Encapsulated stains are fantastic at low fire and they can be mixed to fine-tune the color. If you are targeting a specific or exotic color then the ability to achieve it will be determined by your ability to source an exotic stain!

The melt is very mobile at 04 yet not significantly more mobile at cone 1 (even up to cone 2). And it has the amount of SiO2 and Al2O3 that a cone 6 glaze has yet melts well at 06! There is some kind of magic with this chemistry!

It hardens to a powdery surface, some gum solution is required to make it dry hard for dipping (for each 100g of powder mix start with 73g water and 7g Laguna gum solution). To make a brushing glaze: For each 100g of powder mix start with 125 water, 1.5 CMC gum and 1.5 Veegum and blender mix (add water if it gels too much). We find the about 330g of powder produces a 500ml (about 1 pint) jar.

This recipe also has implied adjustability (by increasing the low expansion Frit F-69 at the expense of Frit F-524).

Pictures

G3879 Clear glaze on Plainsman L211 - Cone 04

Glossy, crystal clear, no crazing! And this is a 42 mesh body containing zero talc.

Melt fluidity comparison with #1 commercial clear

We tested half-a-dozen commercial clears and found G3859 to be the best all-around one. This one has a very similar melt fluidity.

G3879 on Plainsman L210, L215 at cone 04

These are 42 mesh low fire bodies. They normally have issues with pinholing but using this glaze the results are stunning. The L210 contains no talc, the L215 has 10%, yet this glaze does not craze on either one (over time it shivers on the L215).

G3879 on SIAL 25F, Plainsman J2, L4170 TerraCotta

These are very different bodies. The leftmost contains talc to raise the thermal expanison to help prevent crazing with commercial glazes. The center one contains nepheline syenite (for the same purpose). The terra cotta on the right is just Redart and ball clay. This glaze fits are all three!

After a year, both the 25F and J2 were difficult to break, very strong!

Sial 10F, 25F with G3879 clear glaze at cone 03

Tile like these were done on a variety of bodies and fired at different temperatures. After a year:

Sial 10F

Cone 02: No crazing

Cone 04: Moderate crazing over time

Cone 06: Severe crazing

Cone 03: No crazing

Sial 25F

Cone 1: No crazing

Cone 03: No crazing

Cone 04: Crazing badly

L215

Cone 04: No crazing

L210

Cone 04: No crazing

L212

Cone 04: Crazing

Cone 1: No crazing

L213

Cone 04: No crazing

G3879 Clear on L4170 TerraCotta Casting

The clear glaze is G3879. The white on the outside of the one on the left has 10% added zircopax. The overglaze colors are Spectrum Majolica colors.

G3879 with 5% Tin Oxide on SIAL 10F

When mixing Tin (as an opacifer), it is very important to mix it well. The one on the left was mixed poorly (at high speed with my propeller mixer but not for long enough). The one on the right was mixed much better and so produces better opacity. Tin is expensive so this is important.

This was not crazed after a year (cone 03).

G3879 on Plainsman Buffstone - cone 03

Buffstone is an entry-level low-price body not intended to fit commercial glazes. Yet this glaze fits at cone 03 (still fitting after a year)! And without any surface defects.

At cone 04 it does craze over time.

G3879 Zircon White on SIAL 25F, 10F - cone 03

10% zircopax has been added. It is melting well so the percentage could be increased for great opacity on red burning bodies.

G3879 at cone 1 on SIAL 10F, 25F

Crystal clear, no running. Perfect!

GBMF test on G3879 at cone 1

It is not running and flowing nearly as much as expected. The melt surface tension holds it in place, so it should be able to fire to cone 2 and beyond.

G3879 on terra cotta at cone 04, 02, 1

This is on the L4170 body, it is a lighter firing product, 25F, from SIAL. After use on various bodies, it was clear that fit at cone 03 is better than at 04 and much better than 06.

G1916M, G3879, G2931K on L215 - Thick

Thickly applied encourage poor fit to show up.

Clearly, as shivering and cracking demonstrate, G3879 is under excessive compressive on L215.

The other two are not showing any issues (other than heavy bubbling because of the thickness).

G1216M is a blend of 3124/3124 with kaolin. G2931K is the Zero3 clear.

L213 with G3879 glaze at cone 04

Survived 325F:IceWater test with almost no crazing. However there was a little shivering on the rim after a month. Another mug had no crazing on the inside after several months.

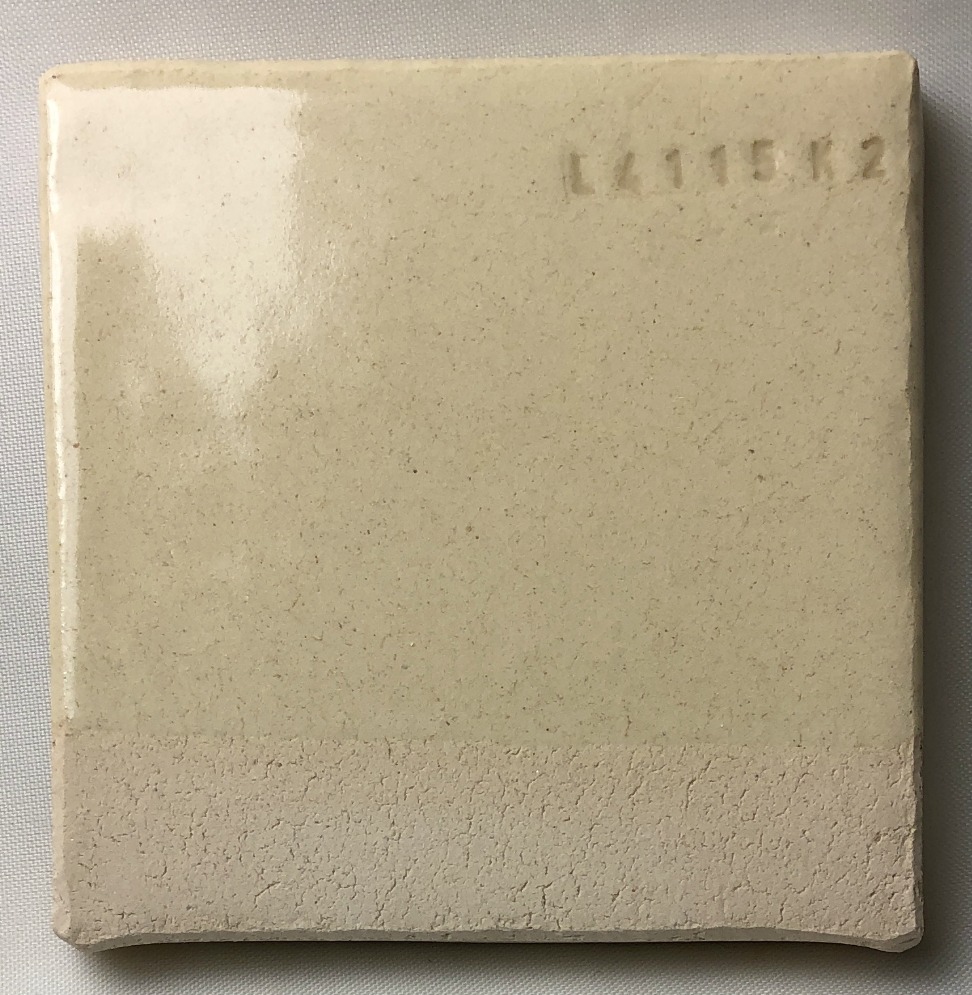

G3879 on L4115J2 buff body at cone 04

Glaze is ultra clear.

It was refired at cone 022 to apply a decal.

It was 325F to icewater tested without crazing.

It was waterlogged (the bottom is bare clay) and then put in a microwave for two minutes. Despite getting incredibly hot it did not fracture or craze! Was still fitting after a year+.

G3879 on SIAL 10F at cone 02

No crazing after several months. Flawless service.

Variations

B - Tin White

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Cone 04+ UltraClear Glossy Base" id="154451" key="PFG941Zz" date="2025-04-06" codenum="G3879"> <recipelines> <recipeline material="Fusion Frit F-524" amount="850.000" tolerance=""/> <recipeline material="Fusion Frit F-69" amount="40.000" tolerance=""/> <recipeline material="EPK" amount="90.000" tolerance=""/> <recipeline material="Silica" amount="45.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2019-04-15, Modified: 2025-04-06 20:40:46

Cone 04 UltraClear Low-Expansion

|

Code # G3879C |

Batch # -2 |

| Materials | Amt | |

|---|---|---|

| Fusion Frit F-524 | 750.000 | 73.17% |

| Fusion Frit F-69 | 140.000 | 13.66% |

| New Zealand or Grolleg kaolin (Grolleg Kaolin) | 90.000 | 8.78% |

| Silica 45 micron (Silica) | 45.000 | 4.39% |

Total:1,025.00

Auto Unity Formula

|

Si:Al: 8.0:1 6.2 (Molar:5.8) 1.1 Cost 2.73 per kg |

Notes

An adjusted version of G3879 to reduce thermal expansion. It switches the silica to 45 micron (325 mesh) for better dissolution in the melt. And it increases the frit low-expansion F-69 (the Fusion equivalent of Ferro 3249) at the expense of F-524.

This also switches to whiter burning kaolin (New Zealand), that improves transparency and removes the amber coloration.

It still fires to the same crystal clear on light burning bodies (but clouding on terra cottas unless applied thinly). And is fitting pieces better.

For a dipping glaze we mix 1500g powder to 1125g water (57%/43%) to get a specific gravity of 1.54. This produces 1.7 litres. This builds up thickness quickly on Snow clay (because it is so absorbent).

For a brushing version we mix 350g powder with 5g Veegum and 5g CMC gum, shake this an add it to 450 water and then mix in a kitchen blender. This produces a gelled slurry that paints well.

Pictures

G3879C is firing much whiter, why?

Cone 04. All three clear glazes are on the same body. Left to right: Amaco LG10, G3879C recipe, Crysanthos SG213. The middle one employs Fusion Frit F-524, it is more expensive. But look at the benefit: It fires much more transparent so the piece is much whiter. And it is not crazing or pin holing. And it is glossier.

G3879C, G1916Q, G1916QL1 on L213 Cone 04

The move from ball clay to New Zealand kaolin (centre mug vs right mug) greatly improves the clarity (because of the reduction in iron and titanium).

G3879C vs. G1916QL on L4410K low fire white

The iron from the ball clay is the reason the glaze on the right is off-white.

Cone 04 G1916QL1 vs G3879C melt flow comparison

G1916QL1 is more melt fluid so it is likely useful before cone 04. But G3879C is also very fluid (it also has a higher surface tension). Both are producing textbook high quality flows.

G3879C, G1916QL1 on L4410L Bisque 1800 glaze cone 04

No crazing after weeks of use, ultragloss.

Frit 524 has much less iron, that is why that mug is so much whiter.

After several months at home the G3879C did craze.

G1916QL1. G3879C, G3879G1 on L213 tiles - Cone 04

These are all craze-free after several months.

G3879C on L4410P dolomite body at cone 04

The outside glaze is Spectrum 336. The G3879C is our recipe, a base transparent that we have been tuning to reduce the thermal expansion as much as possible to fit our 50:40:10 BallClay:Dolomite:Nepheline body. The result is glaze compression, it is now under enough compression on the inside of this piece that it is forcing it apart.

G3879C on L215, Buffstone at cone 02

Clouding badly on terra cotta, better on the white body.

G3879C on L4170B at cone 04 with L3685Z6 engobe

No crazing after six months or more.

An even but not too thick application was achieved by dipping, not brushing.

Testdata

LDW - LOI/Density/Water Content

| WWGT | DWGT | H2O | LOI | DENS | |

| 1 | 11.4 | 6.43 | 43.6% |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Cone 04 UltraClear Low-Expansion" id="202474" key="TCN7BG52" date="2022-12-19" codenum="G3879C"> <recipelines> <recipeline material="Fusion Frit F-524" amount="750.000" tolerance=""/> <recipeline material="Fusion Frit F-69" amount="140.000" tolerance=""/> <recipeline material="New Zealand or Grolleg kaolin" lookup="Grolleg Kaolin" amount="90.000" tolerance=""/> <recipeline material="Silica 45 micron" lookup="Silica" amount="45.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2019-04-15, Modified: 2022-12-19 22:22:22