Red Art Cone 1 Clay Body

|

Code # L4163 |

Batch # -2 |

| Materials | Amt | |

|---|---|---|

| Redart | 60.000 | 58.82% |

| OM4 | 30.000 | 29.41% |

| Talc | 10.000 | 9.80% |

| Bentonite | 2.000 | 1.96% |

| Additions | ||

|---|---|---|

| Iron Oxide Red | 0.500 | 0.49% |

Total:102.50

Notes

Very smooth.

Feels similar to 20% talc bodies, they have great plasticity when vacuum pugged but poor when made using a slurry and plaster batt. This has 7% drying shrinkage, that means it will be super plastic.

Fired color is excellent red at cone 1. And the porosity of 2% qualifies it to be a stoneware. Often, getting stoneware density means losing the color, but that has not happened here.

Solubles are not evident on the mug but they were on the DFAC disk. Not likely enough that a barium carbonate addition is needed.

We did not do extensive tests with glazes but found that bubble clouding is much worse in transparent glazes than at low temperatures.

Pictures

Freshly thrown mugs L4163

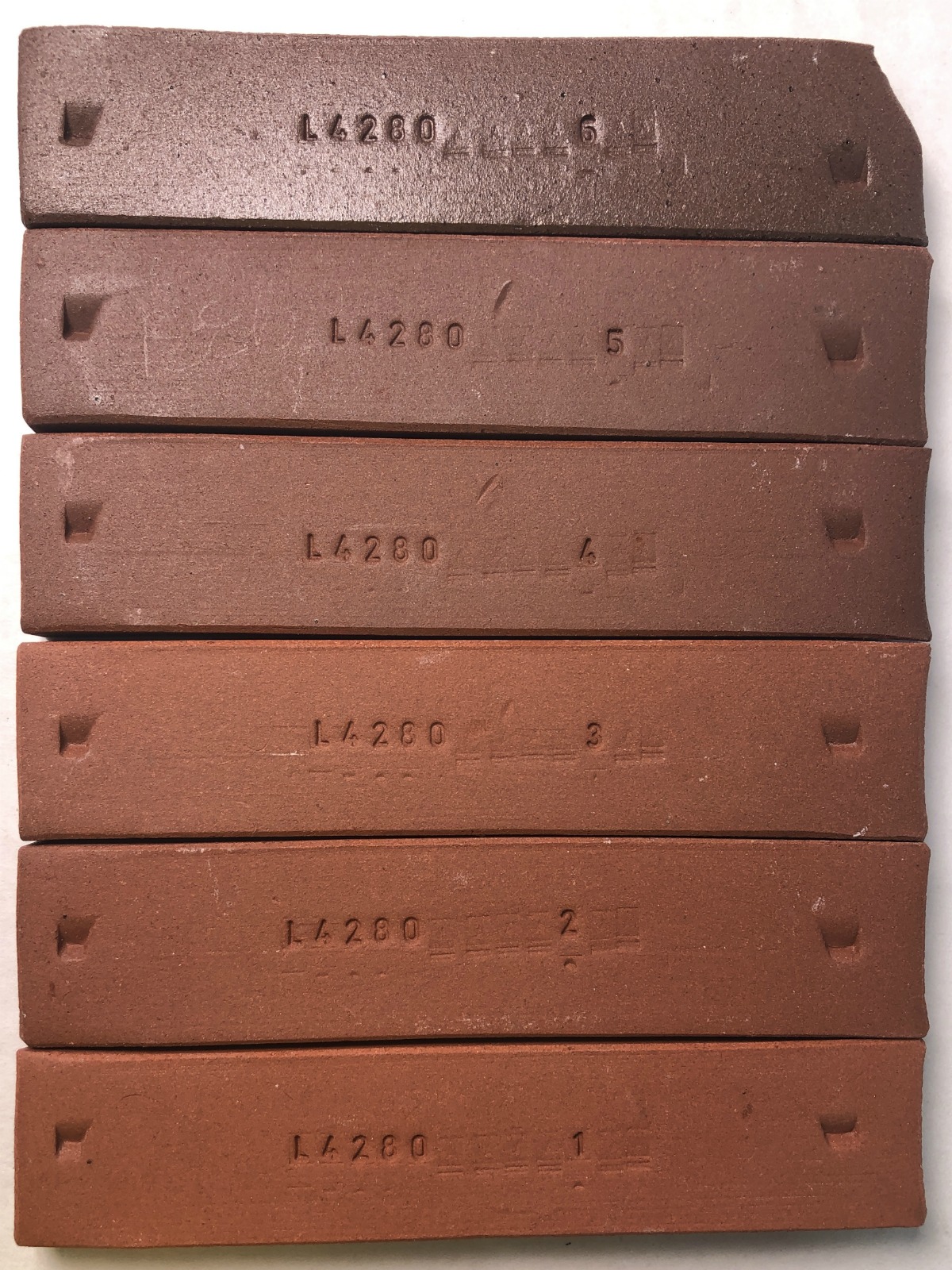

SHAB, DFAC, LDW specimens have dried

L4163 fired at cone 1 - No glaze

L4163 Red Art Cone 1 Body fired DFAC disk

Bars fired at cone 1, 3, 4 (bottom to top)

Actually the bottom bar did not quite get to cone 1 (about 0.5).

Cone 4 is over fired. And likely cone 3. Cone 1 has excellent red color and appears to be very strong.

L4163 fired bars

Fired from cone 5 (top) down to cone 02 (bottom).

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 5 | 93.01 | 86.54 | 35.8 | 36.23 | 4.8 | 7.0% | 7.0% | 1.2% |

| 2 | 92.81 | 85.78 | 34.32 | 34.35 | 3.9 | 7.2% | 7.6% | 0.1% |

| 6 | 92.89 | 86.05 | 35.54 | 35.66 | 2.9 | 7.1% | 7.4% | 0.3% |

| 4 | 93.02 | 87.02 | 35.3 | 35.75 | 0.5 | 7.0% | 6.5% | 1.3% |

| 1 | 93.06 | 36.45 | 6.9% | |||||

| 3 | 92.91 | 87.41 | 35.04 | 36.77 | -2.0 | 7.1% | 5.9% | 4.9% |

SOLU - Soluble Salts

| FIRE | |

| 1 | medium |

DFAC - Drying Factor

| DFAC | SOLD | |

| 7 | c120- | nil |

LDW - LOI/Density/Water Content

| WWGT | DWGT | FWGT | H2O | LOI | DENS | |

| 1 | 25.04 | 19 | 17.73 | 24.1% | 6.7% |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Red Art Cone 1 Clay Body" id="152959" key="ub43kPsS" date="2022-12-07" codenum="L4163"> <recipelines> <recipeline material="Redart" amount="60.000" tolerance=""/> <recipeline material="OM4" amount="30.000" tolerance=""/> <recipeline material="Talc" amount="10.000" tolerance=""/> <recipeline material="Bentonite" amount="2.000" tolerance=""/> <recipeline material="Iron Oxide Red" amount="0.500" added="true"/> </recipelines> </recipe> </recipes>

Born: 2019-03-20, Modified: 2022-12-07 20:24:18

L215 : M390 Mix for Cone 1 Stoneware

|

Code # L4280 |

Batch # -2 |

Notes

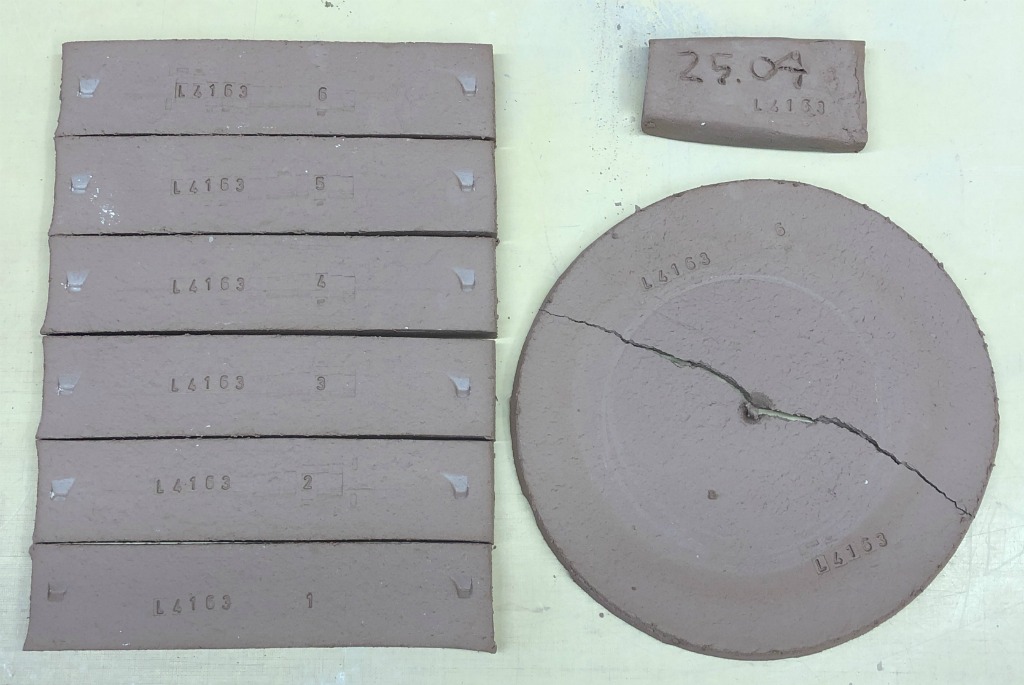

This is a 50:50 mix of Plainsman low temperature L215 terra cotta body and medium temperature M390. The idea was that a mix of a cone 04 body and a cone 6 body would mature mid way between those temperatures. However the L215 did not lower the range of M390 as much as was expected. The body reached a dense stoneware maturity (as indicated by 2% porosity) at around cone 3.5. The 3% porosity it achieves at cone 2.5 is still very durable and we found it worked well with the G3806N recipe (a melt fluid glaze for cone 6 but that is still melting well at cone 2.5).

The cone 3 body color is a nice warm red.

Pictures

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 6 | 93.39 | 88.58 | 41.26 | 41.68 | 6.0 | 6.6% | 5.2% | 1.0% |

| 5 | 93.31 | 88.27 | 42.49 | 43 | 4.8 | 6.7% | 5.4% | 1.2% |

| 4 | 93.19 | 88.25 | 42.73 | 43.5 | 4.0 | 6.8% | 5.3% | 1.8% |

| 3 | 93.22 | 88.65 | 44.05 | 45.22 | 3.0 | 6.8% | 4.9% | 2.7% |

| 2 | 93.29 | 88.82 | 44.61 | 45.9 | 2.6 | 6.7% | 4.8% | 2.9% |

| 1 | 93.28 | 89.17 | 42.25 | 43.75 | 1.0 | 6.7% | 4.4% | 3.6% |

XML (to paste into Insight)

Born: 2020-06-08, Modified: 2022-12-07 20:23:39