BGP Clay:Flyash F 50:50 Mix

|

Code # L4244 |

Batch # -2 |

Notes

This is a mix of 50:50 of Flyash F and BGP (a highly plastic, high iron, low melting earthenware clay). My hope was to get a clay body that would vitrify at a low temperature. However it is unstable, having a very high porosity at cone 2 yet completely melting into a mass of bubbles at cone 6.

The body also has high soluble salts, these are coming from the BGP clay (or perhaps by some sort of interaction during drying).

The plasticity is very poor, this is unexpected given the high plasticity of the BGP clay. A possible reason could be that this material has very small ultimate particle sizes that blocking the action of the clay particles.

Pictures

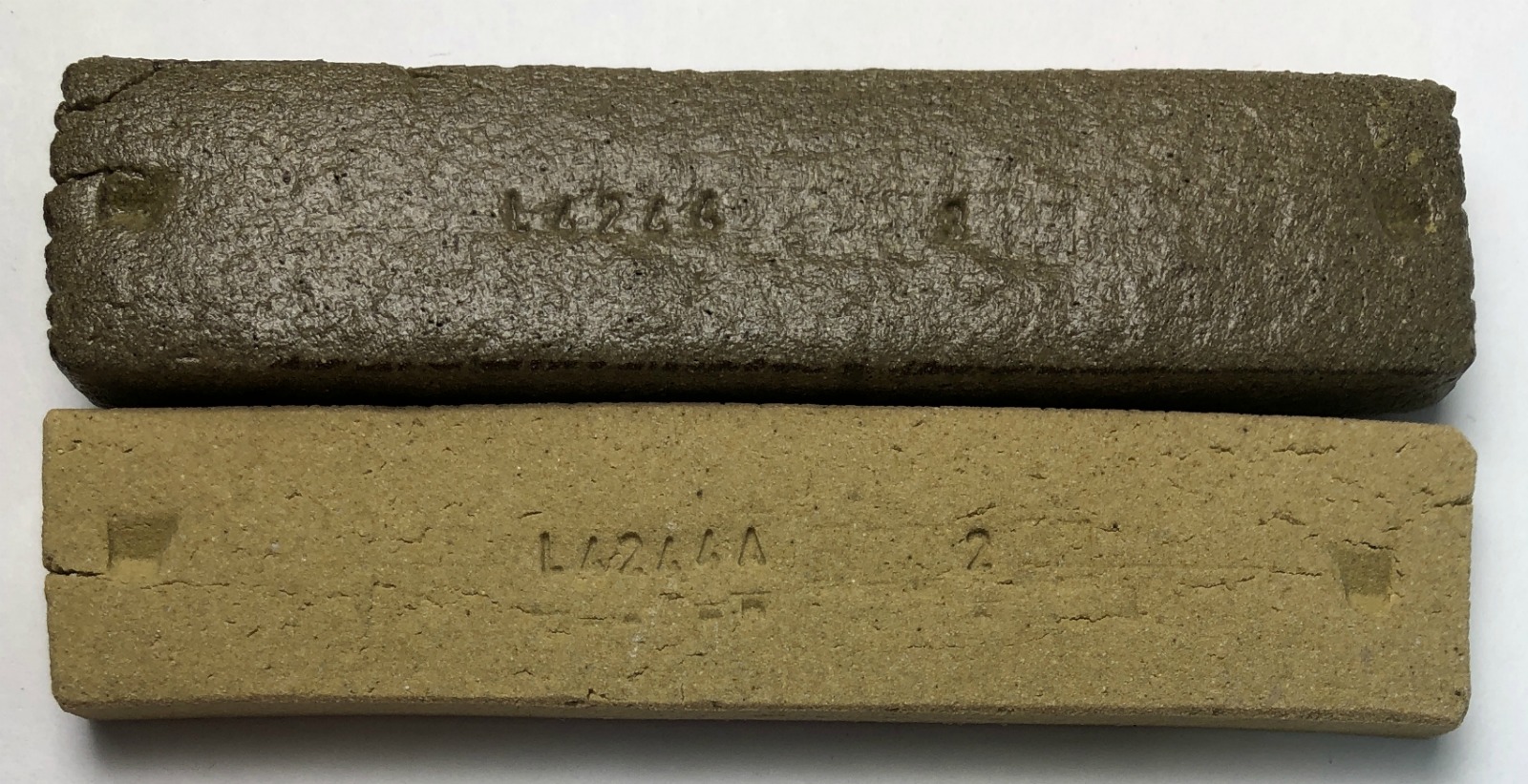

L4244A BGP:Flyash mix melting at cone 10

I fired these to cone 10 by mistake, this is what happens.

L4244, L4244A bars melted at cone 10

These were fired higher than intended.

Bottom: L4244A - much more stable with bentonite

BGP totally melts and the gases from the Flyash are making it an Aero chocolate bar.

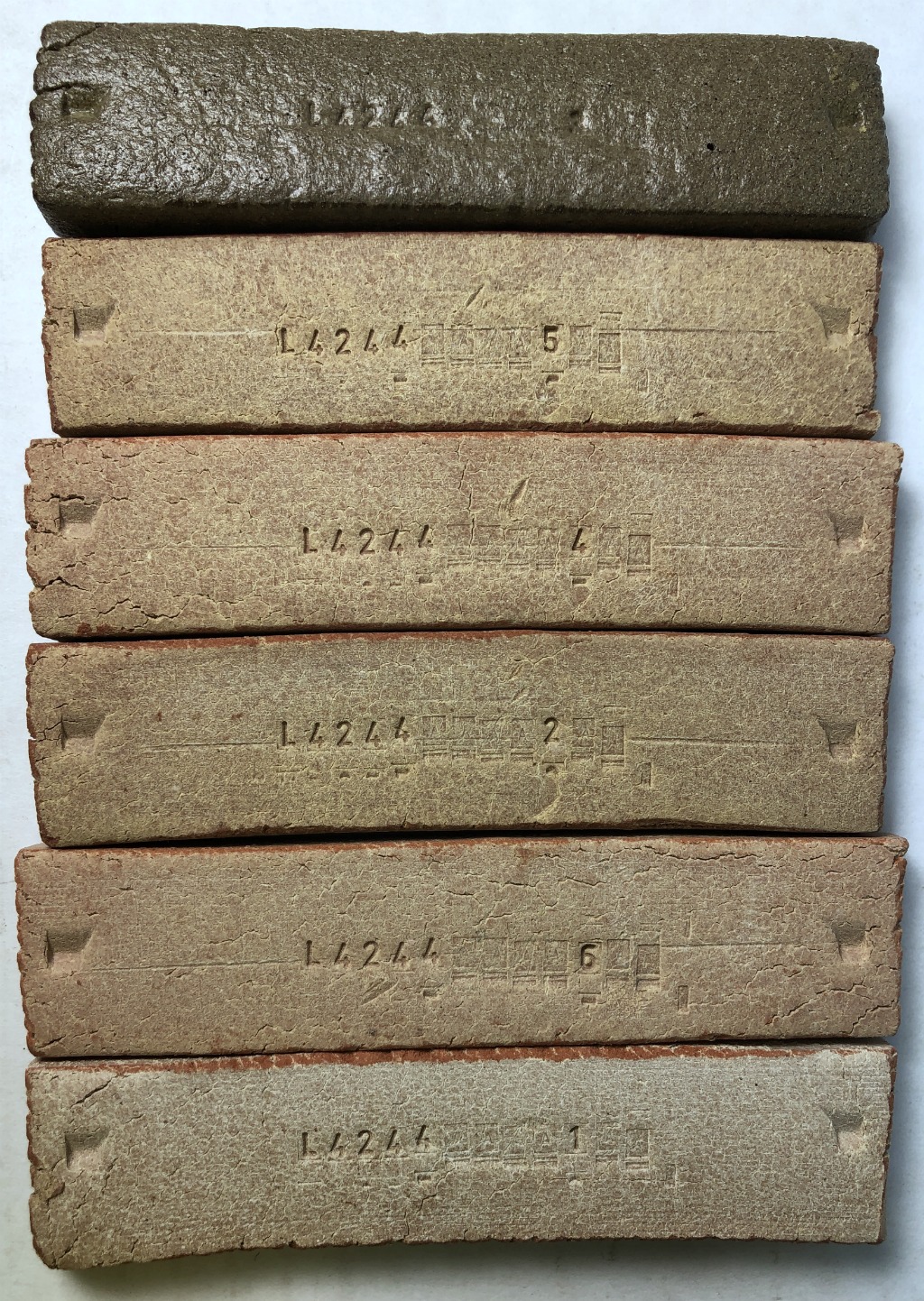

L4244 fired bars

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 3 | 97.42 | melting | 6.0 | 2.6% | ||||

| 1 | 97.21 | 91.96 | 35.67 | 2.7 | 2.8% | 5.4% | ||

| 5 | 97.27 | 90.88 | 34.83 | 39.37 | 2.0 | 2.7% | 6.6% | 13.0% |

| 2 | 97.27 | 92.08 | 37.52 | 43.25 | 1.0 | 2.7% | 5.3% | 15.3% |

| 7 | 97.29 | 2.7% | ||||||

| 4 | 97.22 | 93.32 | 34.42 | 40.73 | -1.0 | 2.8% | 4.0% | 18.3% |

| 6 | 96.88 | 94.71 | 34.09 | 41.55 | -2.0 | 3.1% | 2.2% | 21.9% |

LDW - LOI/Density/Water Content

| DWGT | FWGT | OWGT | H2O | LOI | DENS | |

| 3 | 39.89 | 37.52 | Cone 1 | 5.9% | ||

| 5 | 36.62 | 34.42 | Cone 01 | 6.0% |

XML (to paste into Insight)

Born: 2019-11-28, Modified: 2022-07-14 16:50:53

LaFarge Fly Ash F:Bentonite 95:5 Mix

flyash

|

Code # L4245 |

Batch # -2 |

| Materials | Amt |

|---|---|

| *Fly Ash F | 95.000 |

| *Sodium Bentonite | 5.000 |

Total:100.00

Notes

We received this for testing to see if it can be used as a clay body ingredient (for tile manufacture, for example).

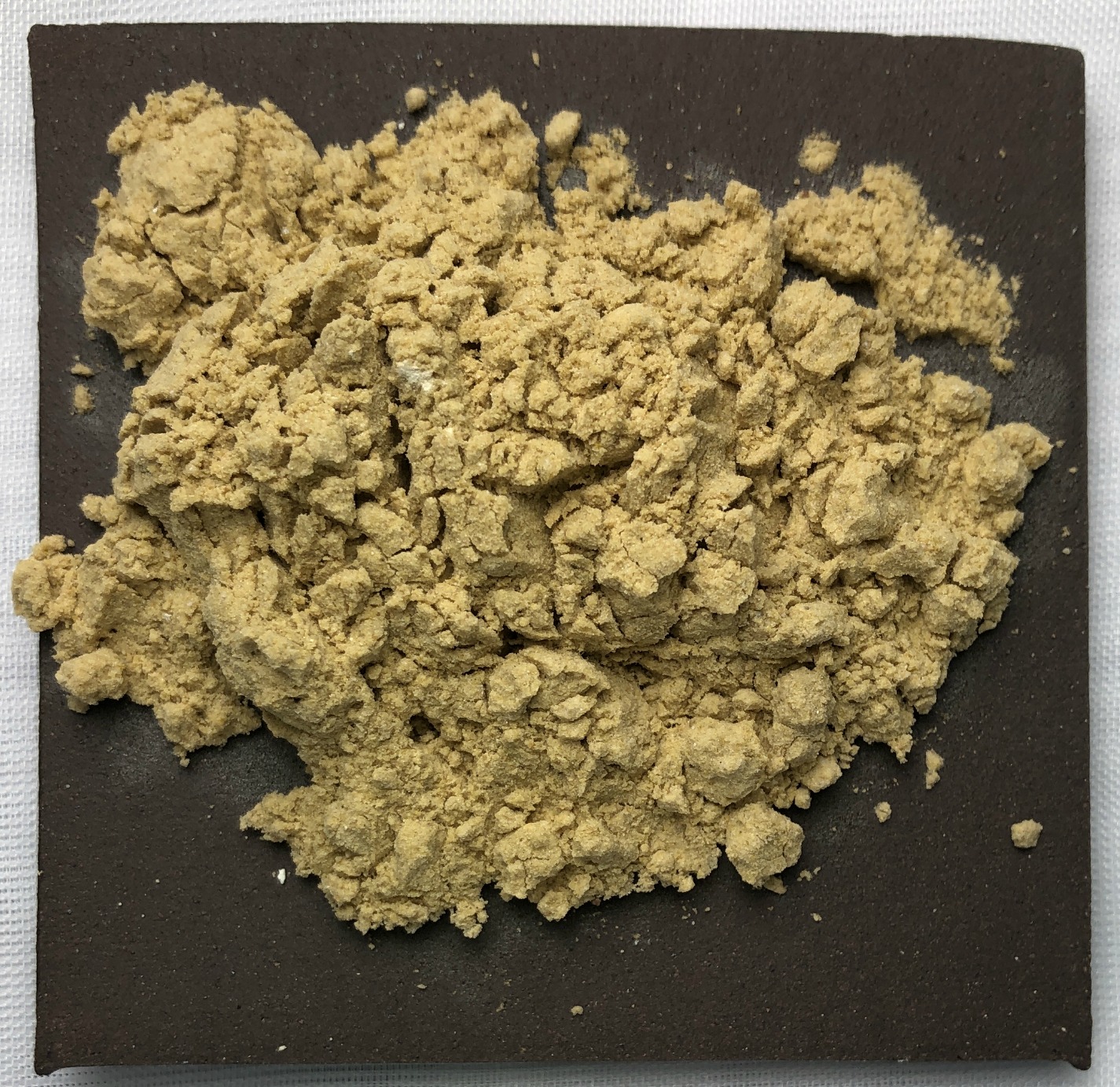

To the touch, this is a very fine powder.

It washes through our test sieves with no problems. That means there are no iron impurities to cause fired specking.

I suspected this has a high LOI (weight loss on firing). But this proved wrong, at cone 01 it is still only 1.7%. That means it has the potential not to cause glaze defects.

This produces so much porosity at lower temperatures it may be a candidate for use in ceramic filters or porosity products. It could likely be dust-pressed at almost 100% (with just a small binder addition).

Anything I make from this tends to be very light-weight. That introduces other possibilities.

The 95:5 mix produced a fairly workable product, this responds really well to this bentonite.

First brick: 2200 95:5 mix and 700 water to get a pressing consistency that would work.

Pictures

Pure Flyash fired to cone 6 (2200F)

It sinters into a very porous mass.

Fly Ash bag

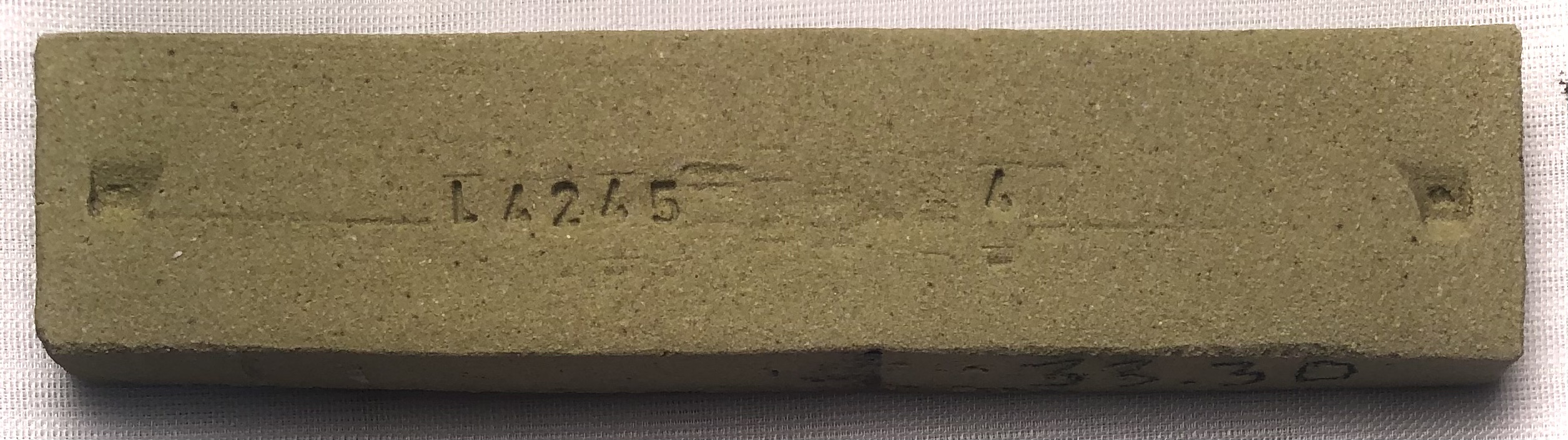

Flyash fired bars

Cone 9, 6, 4, 1 (top to bottom)

The colour is more greenish than this picture indicates

L4245 fired bar - Cone 7

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 3 | 98.6 | 89.43 | 34.44 | 34.44 | 9.0 | 1.4% | 9.3% | 0.0% |

| 4 | 98.48 | 87.44 | 33.28 | 33.3 | 7.0 | 1.5% | 11.2% | 0.1% |

| 2 | 98.64 | 92.23 | 34.05 | 39.58 | 6.0 | 1.4% | 6.5% | 16.2% |

| 6 | 98.64 | 92.31 | 34.03 | 38.42 | 6.0 | 1.4% | 6.4% | 12.9% |

| 1 | 98.61 | 96.12 | 34.05 | 42.4 | 4.0 | 1.4% | 2.5% | 24.5% |

| 5 | 98.03 | 95.95 | 32.54 | 40.16 | 1.0 | 2.0% | 2.1% | 23.4% |

SIEV - Sieve Analysis 35-325 Wet

| TOT | 35M | 48M | 65M | 100M | 150M | 200M | 325M | |

| 1 | 100 | .04 | .14 | .50 | 1.52 | 3.60 | 8.29 | 14.02 |

LDW - LOI/Density/Water Content

| DWGT | FWGT | H2O | LOI | DENS | |

| 1 | 34.3 | 33.73 | 1.7% |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="LaFarge Fly Ash F:Bentonite 95:5 Mix" keywords="flyash" id="166925" key="irbvuG6P" date="2022-07-14" codenum="L4245"> <recipelines> <recipeline material="Fly Ash F" amount="95.000" tolerance=""/> <recipeline material="Sodium Bentonite" amount="5.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2019-11-27, Modified: 2022-07-14 16:50:42

Flyash F:Bentonite 10:90

|

Code # L4244A |

Batch # -2 |

| Materials | Amt |

|---|---|

| *Fly Ash F | 90.000 |

| Bentonite | 10.000 |

Total:100.00

Notes

Objective was to create a clay body of the highest possible percentage of Flyash. In fact, this is more plastic and dries harder than a 50% plastic earthenware clay (BGP) version (L4244), likely because the flyash has very fine ultimate particle sizes.

This has an incredibly low drying shrinkage (a big surprise given the super fine particle size of bentonite). Workability was just good enough to be able to roll test bars. However their dry strength was much better than expected.

The cone 02, 01, 1, 2 fired bars look identical.

Refired sample 7 to cone 10, #1 to cone 8.

This is producing a dense stoneware at cone 8. By adding more bentonite it should be possible to get much better workability and the bentonite may flux it to vitrify at cone 6.

Like L4245, it produces a highly porous body at lower temperatures.

Pictures

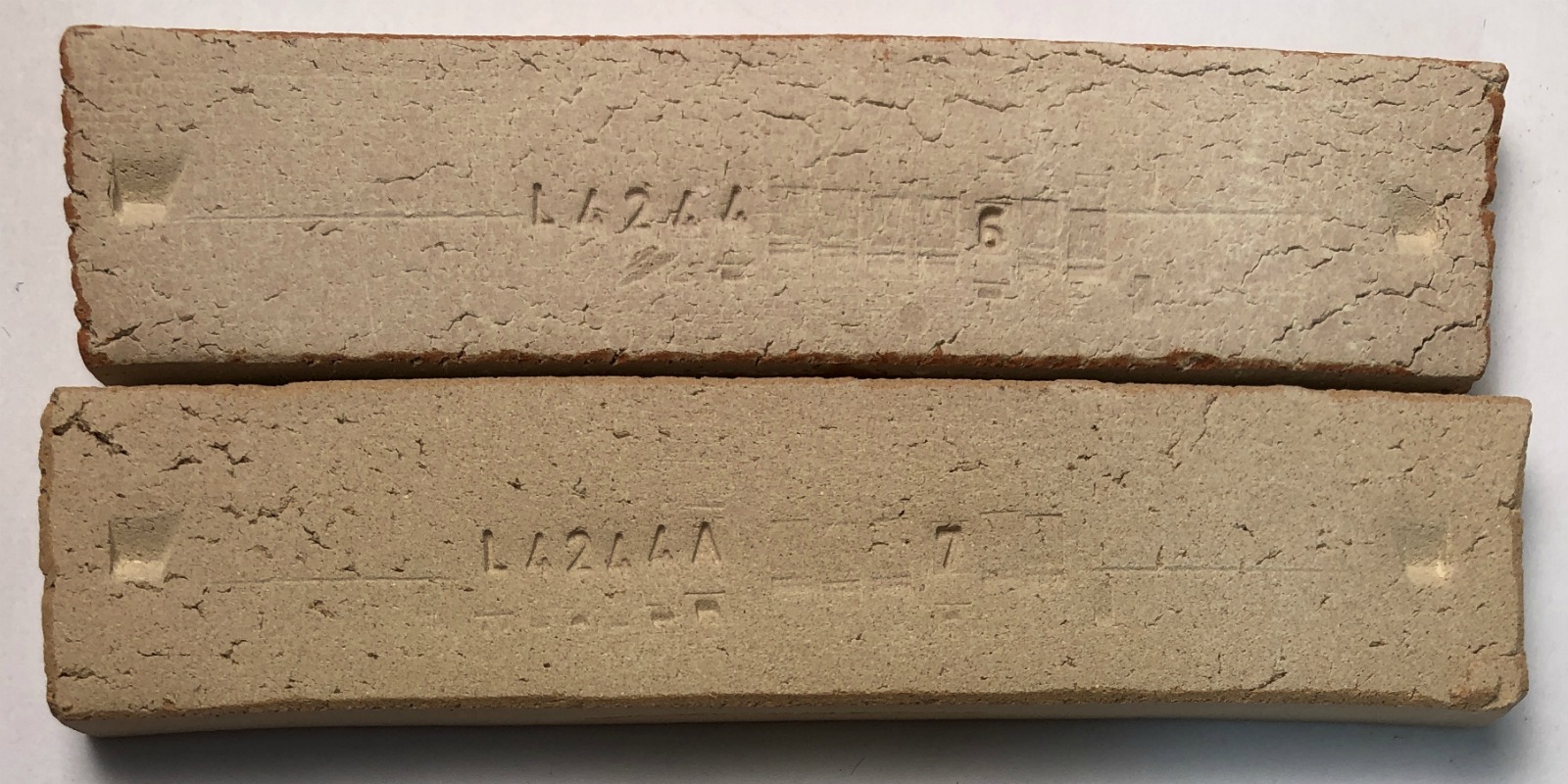

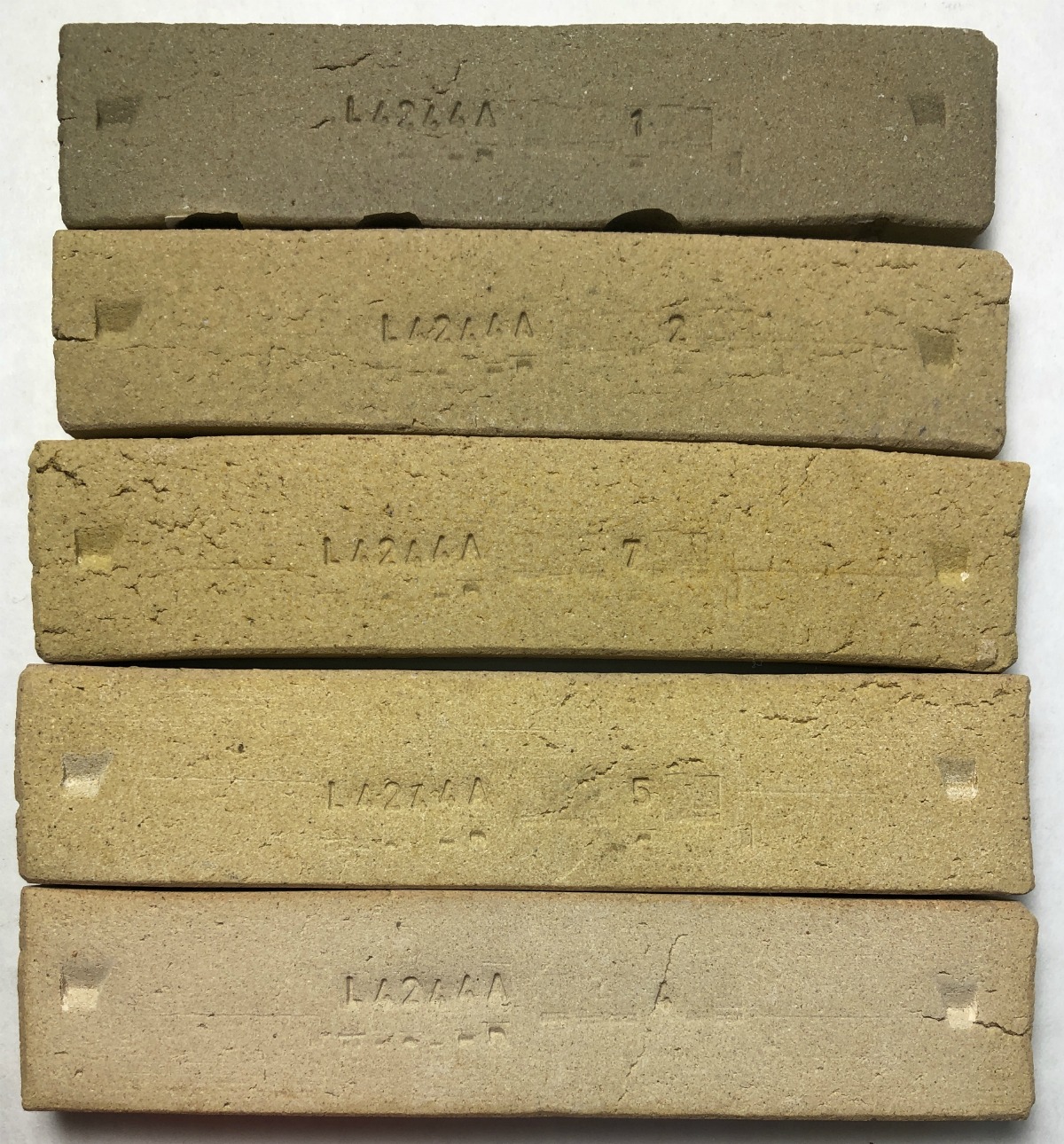

L4244, L4244A bars melted at cone 10

These were fired higher than intended.

Bottom: L4244A - much more stable with bentonite

BGP totally melts and the gases from the Flyash are making it an Aero chocolate bar.

L4244, L4244A bars at Cone 02

Both are very light (losing weight during firing).

L4244, L4244A bars at Cone 6

L4244A fired bars

Cone 2,6,8 (bottom to top)

To top bar, fired at cone 8, it surprisingly dense and strong. The bottom one is surprisingly light and porous. This is a wide range of temperatures, so this same body has a wide range of potential applications.

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 1 | 98.24 | 88.53 | 33.06 | 33.1 | 8.0 | 1.8% | 9.9% | 0.1% |

| 2 | 98.21 | 89.6 | 33 | 37.21 | 6.0 | 1.8% | 8.8% | 12.8% |

| 7 | 98.16 | 92.51 | 34.47 | 41.57 | 4.8 | 1.8% | 5.8% | 20.6% |

| 5 | 98.11 | 94.67 | 33.87 | 42.28 | 4.0 | 1.9% | 3.5% | 24.8% |

| 4 | 98.13 | 94.71 | 33.41 | 41.39 | 2.0 | 1.9% | 3.5% | 23.9% |

| 3 | 98.16 | 94.96 | 33.37 | 41.07 | 1.0 | 1.8% | 3.3% | 23.1% |

LDW - LOI/Density/Water Content

| DWGT | FWGT | OWGT | H2O | LOI | DENS | |

| 2 | 35.5 | 33.45 | Cone 01 | 5.8% | ||

| 4 | 35.47 | 33.37 | Cone 1 | 5.9% |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Flyash F:Bentonite 10:90" id="166958" key="tBb5M7pb" date="2022-07-19" codenum="L4244A"> <recipelines> <recipeline material="Fly Ash F" amount="90.000" tolerance=""/> <recipeline material="Bentonite" amount="10.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2019-11-28, Modified: 2022-07-19 11:30:50

Fly Ash F:Bentonite:BallClay 80:10:10

flyash

|

Code # L4245F |

Batch # -2 |

| Materials | Amt |

|---|---|

| *Fly Ash F | 80.000 |

| Bentonite | 10.000 |

| OM4 Ball Clay | 10.000 |

Total:100.00

Notes

Plasticity good enough for wedging but still just barely good enough to make test bars.

At cone 9 bar is sagging and bending but not bloating!

Pictures

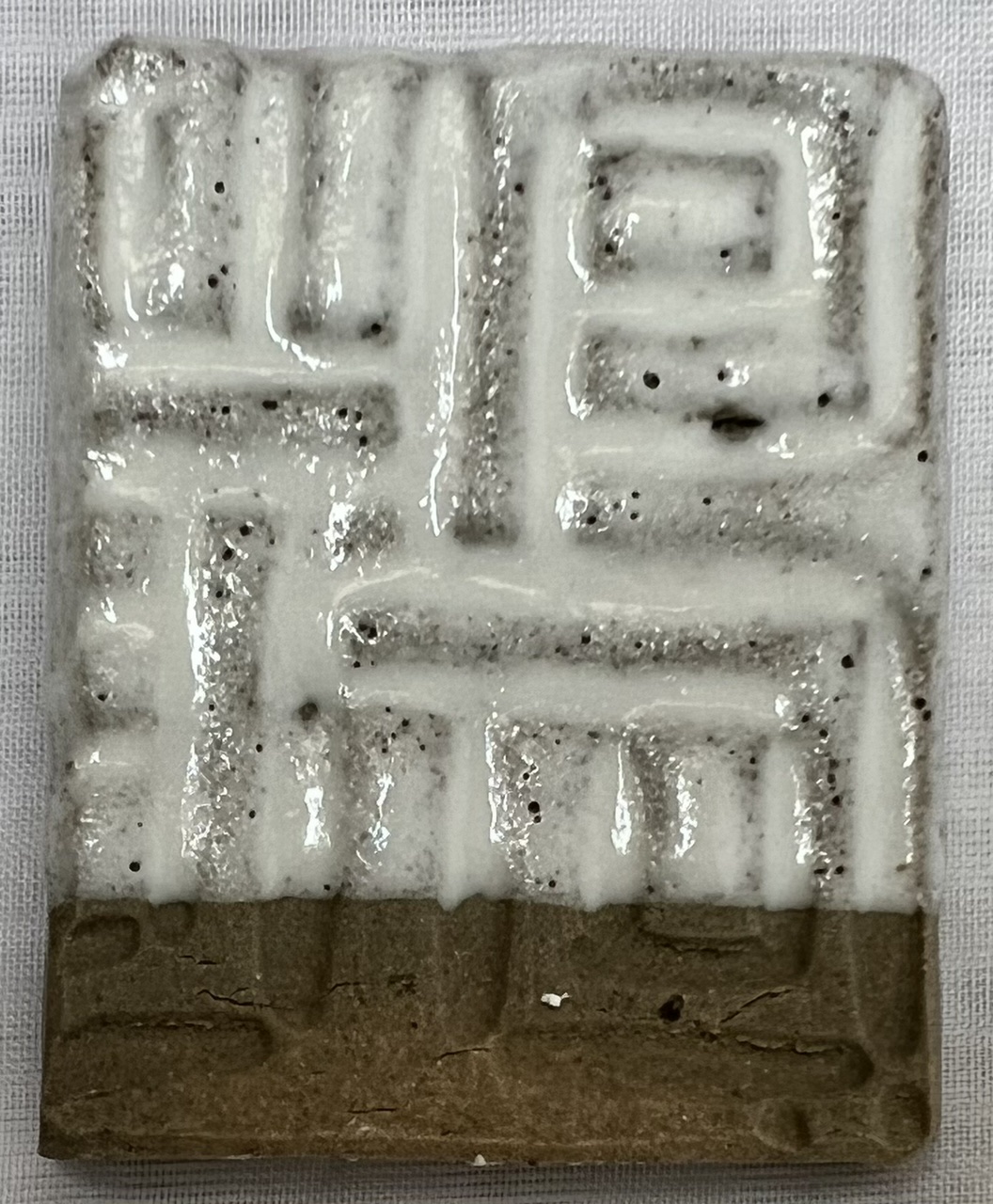

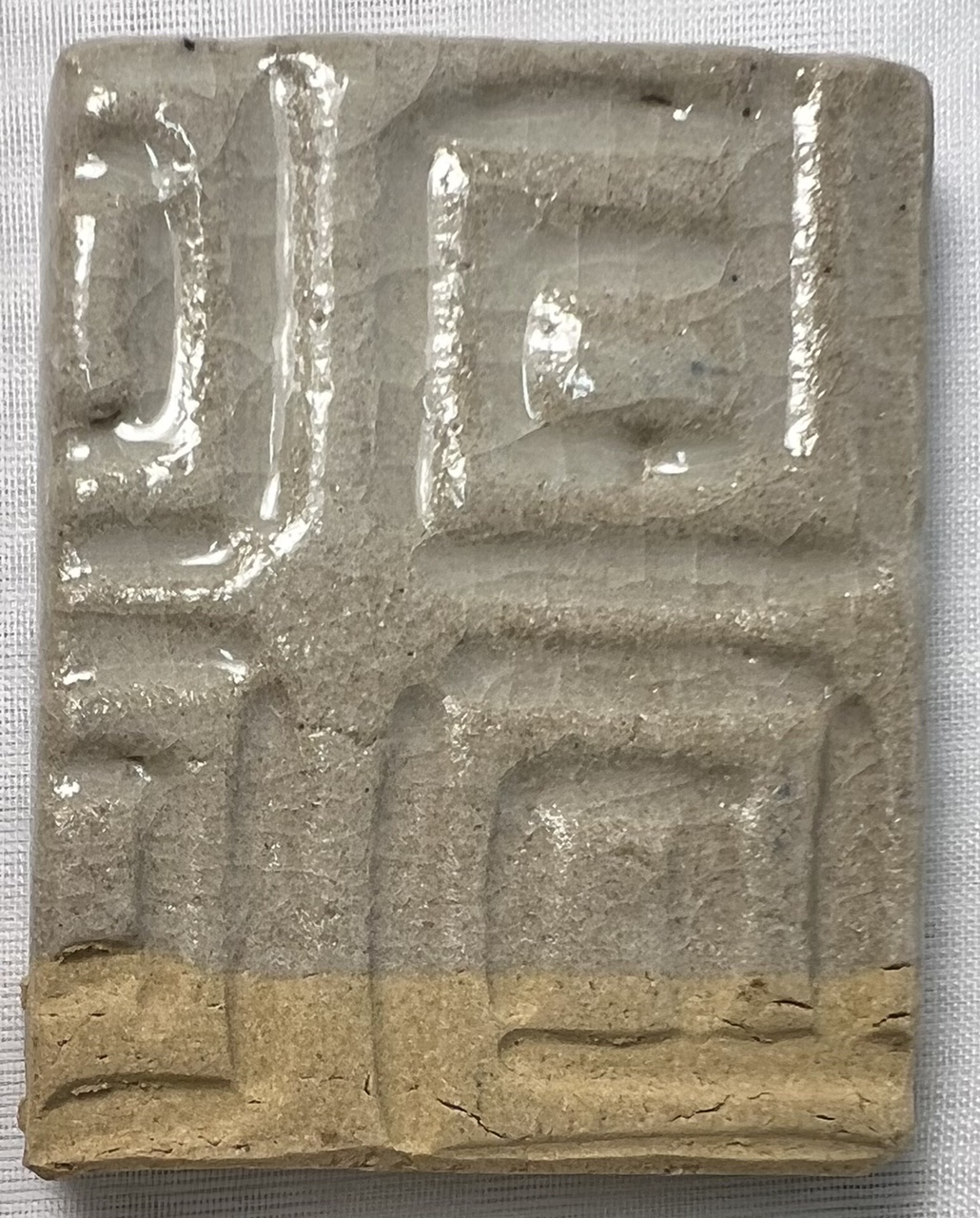

L4245F at cone 7 with glaze

Glaze is G2926B white.

Bubbling indicates plenty of gases are burning off during liquid phase of glaze. Body is also absorbing some of the glaze.

Cone 6 with G2926B

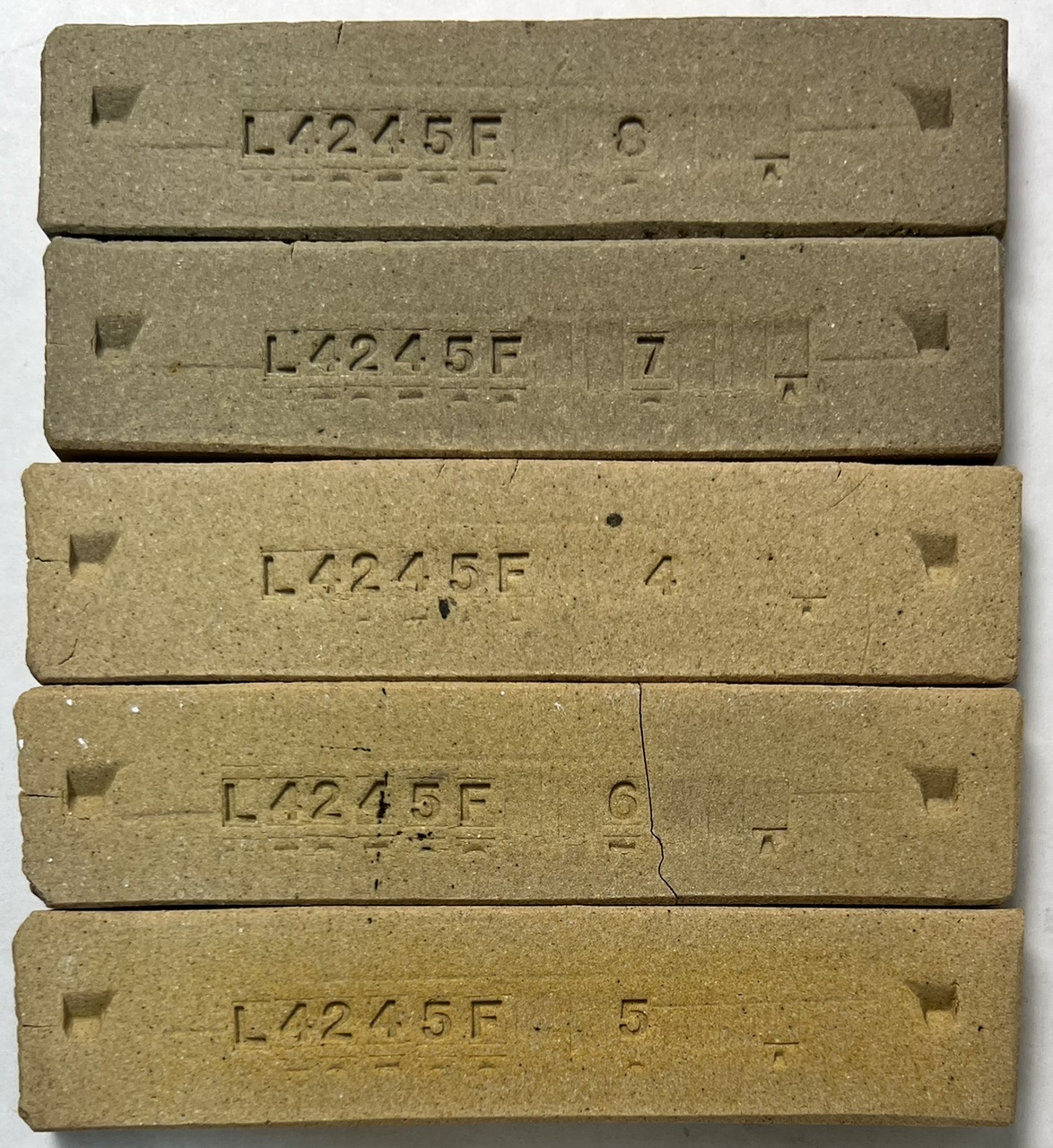

L4245F Fly Ash F:Bentonite:BallClay 80:10:10 fired bars

Testdata

SHAB - Shrinkage/Absorption

| DLEN | FLEN | FWT | BWT | CONE | DSHR | FSHR | ABS | |

| 8 | 97.88 | 86.3 | 34.84 | 34.86 | 8.0 | 2.1% | 11.8% | 0.1% |

| 7 | 97.94 | 86.1 | 35.49 | 36.44 | 7.0 | 2.1% | 12.1% | 2.7% |

| 6 | 98.01 | 90.6 | 33.46 | 39.93 | 5.9 | 2.0% | 7.6% | 19.3% |

| 4 | 97.71 | 90.2 | 32.77 | 37.86 | 5.2 | 2.3% | 7.7% | 15.5% |

| 5 | 97.94 | 91.6 | 33.9 | 40.29 | 5.0 | 2.1% | 6.5% | 18.8% |

| 9 | 98 | bending | 2.0% |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Fly Ash F:Bentonite:BallClay 80:10:10" keywords="flyash" id="221605" key="nTGCmC5h" date="2022-09-06" codenum="L4245F"> <recipelines> <recipeline material="Fly Ash F" amount="80.000" tolerance=""/> <recipeline material="Bentonite" amount="10.000" tolerance=""/> <recipeline material="OM4 Ball Clay" amount="10.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2019-11-27, Modified: 2022-09-06 11:21:59