Project Name

N505, Cushing Satin #71 matte cone 6 glazes

Project Codenumber

UnAssigned

Notes

This project compares N505 (our code number G3955) with our commonly used G2934 MgO matte and G1213Z1 CaO mattes.

Some obvious things can be noted about N505:

-N505 contains no silica and very little clay, it is thus surprising that it even works at cone 6. Low SiO2 and Al2O3 generally mean cutlery marking, running - this is a low temperature glaze being fired at cone 6.

-N505 has a lot of Cornwall Stone, that normally means high KNaO and crazing (however it also has lots of MgO to keep the thermal expansion down).

-N505 contains magnesium carbonate, it can matte glossy glazes at almost any temperature, simply because the particles don't melt with the glaze and affect its ability to smooth out. The MgO is the matteness mechanism and the MagCarb is helping stablize against running. The degree of matteness of N505 is very likely to change with different firing schedules.

Satin White #71 has a more promising chemistry (higher SiO2 and Al2O3). It melts to a satin surface with much less frit or Gerstley Borate than normal, thus being lower in cost.

N505 Base Satin White - Opaque

|

Code # G3955 |

Batch # -2 |

| Materials | Amt | |

|---|---|---|

| Dolomite | 12.000 | 11.32% |

| Gerstley Borate | 14.000 | 13.21% |

| Wollastonite | 10.000 | 9.43% |

| Fusion Frit F621/19 | 8.000 | 7.55% |

| Cornwall Stone | 46.000 | 43.40% |

| EPK | 10.000 | 9.43% |

| Magnesium Carbonate | 6.000 | 5.66% |

Total:106.00

Auto Unity Formula

|

Si:Al: 7.0:1 7.1 (Molar:6.9) 13.6 Cost 0.11 per kg |

Notes

This recipe is from page 2 of booklet: 15 Tried & True Cone 6 Glaze Recipes. The Fusion frit used here is the equivalent for Ferro Frit 3124 in the recipe they quote.

This recipe has very very low Al2O3 and also low SiO2. It is a low-temperature glaze being fired at cone 6, it is thus very runny. It was not a matte until someone added that 6% MagCarb, that is crowbarring the surface to matteness (and roughness). When controlled this produces a more interesting surface and is thus popular with artists and potters.

We were actually suspicious that this glaze would have more issues than it actually does. Although the surface is rough and it does mark and stain, it can be cleaned with effort. The low SiO2 suggests it would cutlery mark but it does seem quite hard. However, on the matter of leaching the jury is still out (a stain needs to be added for testing in an acid). Crazing is another likely problem. Our G3924 recipe, although more boring, excels on all four of these tests.

Equal parts water and powder produced a good slurry.

Pictures

P7033 G2934 Cone 6 Matte vs. the N505 recipe

The G2934 (left) is not running as much as normal, but the melt looks and works great, the surface is very functional and smooth. The difference could be the use on the Fusion frit instead of Ferro.

P7033 G2934 production run vs. G3955

G2934 (right), G3955 (left).

Cone 6 standard drop-and-hold firing.

Results are fantastic, the G2934 surface is perfect.

The G3955 thickens markedly on an contour and runs (thickness of application is light so it could easily have run much more on a longer dip).

G2934 (left) vs G3955 (right) mattes at cone 6

The G2934 is very smooth and this felt marker cleaned off effortlessness. The other required scrubbing and could not be removed completely.

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="N505 Base Satin White - Opaque" id="183847" key="Xi8haJg8" date="2022-11-14" codenum="G3955"> <recipelines> <recipeline material="Dolomite" amount="12.000" tolerance=""/> <recipeline material="Gerstley Borate" amount="14.000" tolerance=""/> <recipeline material="Wollastonite" amount="10.000" tolerance=""/> <recipeline material="Fusion Frit F621/19" amount="8.000" tolerance=""/> <recipeline material="Cornwall Stone" amount="46.000" tolerance=""/> <recipeline material="EPK" amount="10.000" tolerance=""/> <recipeline material="Magnesium Carbonate" amount="6.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2020-09-11, Modified: 2022-11-14 11:15:56

Cone 6 Magnesia Matte Base

|

Code # G2934 |

Batch # -2 |

| Materials | Amt | |

|---|---|---|

| Ferro Frit 3124 | 19.400 | 19.01% |

| EP Kaolin | 18.300 | 17.93% |

| Dolomite | 23.500 | 23.03% |

| Silica | 26.960 | 26.42% |

| Calcined Kaolin | 13.900 | 13.62% |

Total:102.06

Auto Unity Formula

|

Si:Al: 6.0:1 5.8 (Molar:5.7) 13.6 |

Notes

This matte recipe was developed from our high-dolomite recipe originally used to compare shipments of dolomite for consistency (but with much higher Al2Oe and SiO2). In our standard firings, this recipe produces both good mattenss and a durable surface coupled with a low chance of crazing on almost any body. This is not a reactive matte, it is intended for functional and durable surfaces. This is also adjustable (the degree of matteness).

WARNING: The degree-of-matteness is very dependent on the cooling rate in the kiln. Fast cooling (e.g. our PLC6DS firing schedule in a lightly-loaded or smaller kiln) produces a silky matte or even glossy surface. Slower cooling (e.g. a heavily loaded kiln or the C6DHSC schedule) may produce a matter surface than you need (more subject to cutlery marking). Control the degree of mattness in three ways:

-Changing the firing curve

-Blending in some glossy G2926B

-Adjusting the recipe to source more SiO2.

This has a very low thermal expansion, meaning it will not craze on just about any clay body. However, on some, it could shiver or lead to glaze compression issues. Use G2934Y2 if this is a problem for you.

https://plainsmanclays.com/g2934 documents this recipe using a variety of stains.

Pictures

Incredible cone 6 speckle body with G2934 matte glazes

This clay, L4115J3S, a Plainsman 3D-based body, fires vitreous and dense, yet there is no hint of bloating. With these matte glazes very durable and functional pieces are produced.

Outside glaze on both is G2934W (adds 10% zircopax). In our C6DHSC firings this produces as matte a surface as is possible without having excessive staining problems. To add a little gloss we blend in 15% of the G2926B Glossy clear.

Inside glazes:

Left mug: L4423A (85:15 mix of G2934 matte/G2926B clear glossy). It does not contain any zircopax.

Right mug: G2926B ball milled glossy, producing a striking visual yet highly functional surface.

These mugs look as close to cone 10R dolomite-glazed ware as we have ever seen! Especially the L4423A recipe

The difference cooling-rate makes

These are the G2934 black glaze at cone 6. The piece on the left was fired using the C6DHSC firing schedule (drop-and-hold at 2100F then 150F/hr to 1400F). The one on the right was fired using the PLC6DS schedule (drop-and-hold at 2100F then free-fall from there). The slow cool gives the glaze on the left time to crystallize, creating a stony matte.

G2934 + 5% Titanium thinner/thicker on M390

G2934 Cone 6 Matte + 4% iron oxide

Left: PLC6DS firing

Right: C6DHSC firing

G1214Z CaO matte vs 2928C MgO matte

Despite being a matte G1214Z is well melted, more than a glossy transparent would be. The development of calcium silicate crystals depends on this high melt fluidity.

The MgO matte on the right (the G2934 recipe made using Ravenscrag Slip) is much less fluid. This also is needed, the viscous melt prevents the surface from flattening during cooling.

This test was not slow cooled.

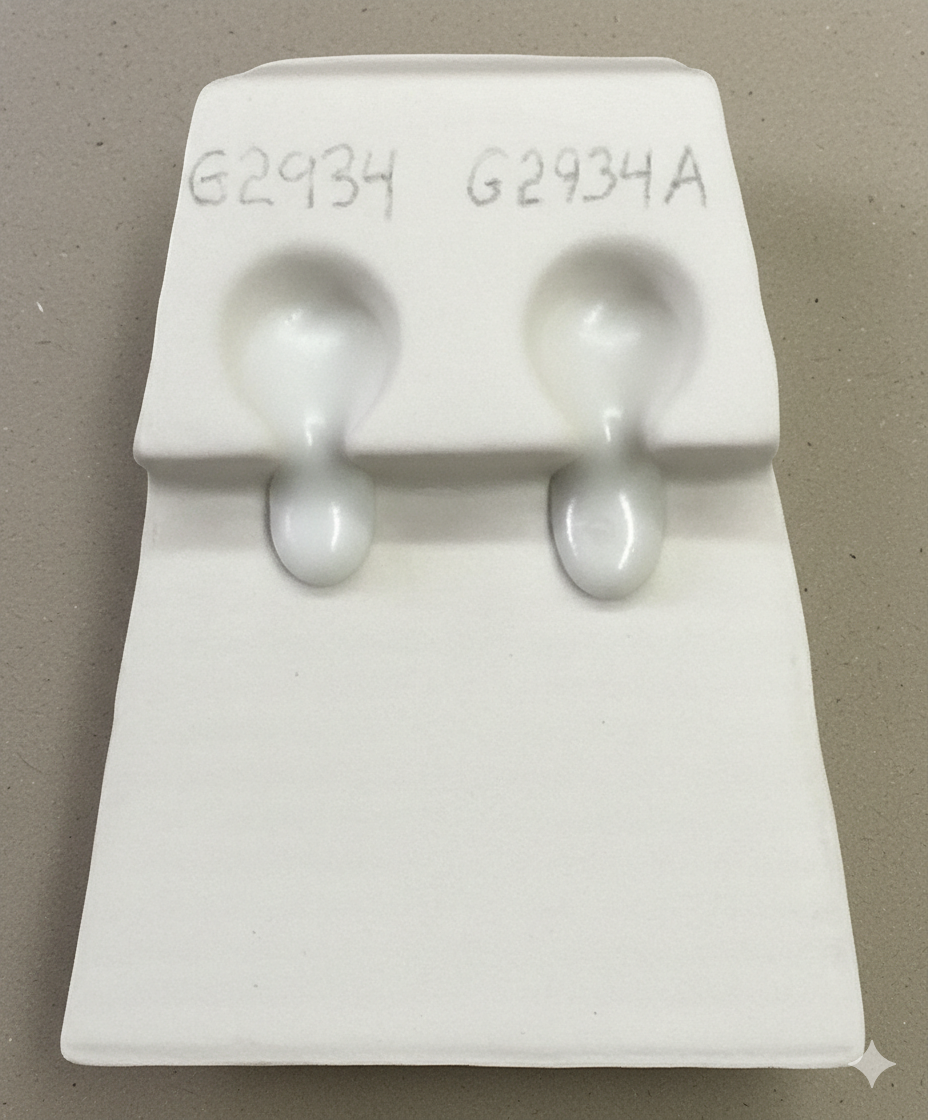

G2934 vs G2934A at cone 6

G2934A is the dolomite testing recipe with added SiO2 (from 2.37 to 3.13) and slightly lower Al2O3.

This has not glossed as expected, the MgO is still working. And it is melting better, unexpected since SiO2 is a refractory oxide. But it appears the reduction in Al2O3 more than made up for the increase in SiO2.

True mattes should still be matte if overfired

GBMF test to compare.

The G2934 is a high-MgO matte, it melts well and does not cutlery mark or stain easily. As evidence that it is a true matte, notice that it is still matte when fired to cone 7 or 8. VC71, while having a similar pleasant silky matte surface at cone 6, converts to a glossy if fired higher (suggesting that its cone 6 matteness is due to incomplete melting). For the same reason the VC71, it is whiter in color (but as soon as it begins to melt and have depth the color darkens).

G2934 with Hemlock Green, Pansy Purle Stains

Cone 6 GBMF tests: 10 gram balls have been melted down onto a tile at cone 6.

Top: G2934 with normal flow.

Left: 8% 6213 Hemlock Green. Needs significant flux.

Right: 8% 6305 Violet stain. Flowing a little less, needs a little flux.

Melt flow comparison: G2934 with Frit 3124, Frit F-19

Fusion Frit F-19 is giving a more fluid melt.

URLs

Prepared public do..om Plainsman Clays

Typecodes

C6-Crawl Cone 6

Alternate Code Number:MG6CDM

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Cone 6 Magnesia Matte Base" id="56852" key="JMvX82e5" date="2026-01-15" typecodes="C6" codenum="G2934" picturebasename=""> <recipelines> <recipeline material="Ferro Frit 3124" amount="19.400" tolerance=""/> <recipeline material="EP Kaolin" amount="18.300" tolerance=""/> <recipeline material="Dolomite" amount="23.500" tolerance=""/> <recipeline material="Silica" amount="26.960" tolerance=""/> <recipeline material="Calcined Kaolin" amount="13.900" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2014-03-21, Modified: 2026-01-15 18:53:45

Cone 6 Calcium Matte v2

|

Code # G1214Z1 |

Batch # -2 |

| Materials | Amt | |

|---|---|---|

| Wollastonite | 27.000 | 26.73% |

| Ferro Frit 3124 | 36.000 | 35.64% |

| EPK | 20.000 | 19.80% |

| Silica | 5.000 | 4.95% |

| Calcined Kaolin | 13.000 | 12.87% |

Total:101.00

Auto Unity Formula

|

Si:Al: 5.5:1 7.0 (Molar:7.1) 2.9 Cost 0.23 per kg |

Notes

This is an adjustment to the original G1214Z recipe. The chemistry of this is the same, but the 37 raw kaolin in the original has been split to a combination of raw:calcined kaolin to reduce drying shrinkage (preventing cracking as it dries and crawling during firing). If unavailable, you can make your own calcined kaolin by roasting the powder in a container in a bisque firing.

Like G1214Z, this achieves a mat surface by incorporating a very high percentage of CaO in the chemistry. While visually appealing surfaces can be achieved, especially with slower cooling, leach testing should be done if metal oxide pigments are being used.

For 3000 grams we use 2600 water to get 1.45 specific gravity and good flow properties (no Epsom salts should be needed to gel the slurry, it is naturally thixotropic).

Pictures

3 opacifiers on Coffee Clay, M390 in G1214Z

G1214Z2 on M340, M390 at cone 6

G1214Z at cone 6 with 10% Zircopax and 5% tin oxide

The body is Plainsman M390. The firing schedule is Plainsman PLC6DS. The tin is on the right.

Alternate Code Number:GS6-B

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Cone 6 Calcium Matte v2" id="156545" key="Kk3GmP4c" date="2025-02-04" codenum="G1214Z1" picturebasename=""> <recipelines> <recipeline material="Wollastonite" amount="27.000" tolerance=""/> <recipeline material="Ferro Frit 3124" amount="36.000" tolerance=""/> <recipeline material="EPK" amount="20.000" tolerance=""/> <recipeline material="Silica" amount="5.000" tolerance=""/> <recipeline material="Calcined Kaolin" amount="13.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 1998-04-21, Modified: 2025-02-04 20:59:08

Val Cushing Satin White #71

|

Code # G3892 |

Batch # -2 |

| Materials | Amt | |

|---|---|---|

| Talc | 9.000 | 8.91% |

| Whiting | 16.000 | 15.84% |

| Ferro Frit 3124 | 9.000 | 8.91% |

| Custer Feldspar | 40.000 | 39.60% |

| EPK | 10.000 | 9.90% |

| Silica | 16.000 | 15.84% |

| Bentonite | 1.000 | 0.99% |

Total:101.00

Auto Unity Formula

|

Si:Al: 8.6:1 7.2 (Molar:6.7) 9.1 Cost 0.28 per kg |

Notes

A long time favorite cone 6 matte glaze recipe.

Pictures

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Val Cushing Satin White #71" id="161479" key="2M77wwPY" date="2023-01-19" codenum="G3892" email="gallagher.peggy@gmail.com"> <recipelines> <recipeline material="Talc" amount="9.000" tolerance=""/> <recipeline material="Whiting" amount="16.000" tolerance=""/> <recipeline material="Ferro Frit 3124" amount="9.000" tolerance=""/> <recipeline material="Custer Feldspar" amount="40.000" tolerance=""/> <recipeline material="EPK" amount="10.000" tolerance=""/> <recipeline material="Silica" amount="16.000" tolerance=""/> <recipeline material="Bentonite" amount="1.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2019-08-26, Modified: 2023-01-19 10:52:02