Project Name

G2934Y Variations

Project Codenumber

UnAssigned

Notes

All of these recipes have the same chemistry as the original G2934. But they employ different mixes of materials to source that chemistry. A big advantage of the high-MgO chemistry of these is the low thermal expansion yielded coupled with plenty of Al2O3/SiO2. That means they will not craze on any common clay body and have excellent fired durability.

If the one you want to use contains frit 3249 or F-69 and these are not available in your area then there are two choices: Use the G2934 recipe and blend in the G2926B cone 6 gloss (or another gloss you have) to tune to the matteness needed with the cooling speed of your firings. Or, use the glaze chemistry tools provided in your account at Insight-live.com to create a recipe that calculates to the same chemistry using materials you can get.

These adjustment recipes improve the application and firing performance of G2934 in various ways (as explained with each). But note that if a G2934:G2926B mix has been working for you it might be best to stick that that. These are of most interest to factories that need to minimize risk of defects. The most important advantage that these is a much lower LOI because of sourcing as much MgO from frit as possible (and the rest from talc rather than dolomite). This results in a finer surface texture (that you may or may not want). The MgO-sourcing frits 3249 and F-69 are normally used to lower thermal expansion to prevent crazing, there is no better way to do this. But these frits are expensive.

All of these variations have the same issues with the firing schedule: The speed of cooling affects the degree of matteness. Faster cools are glossier (and more pleasant to the touch). If you cannot cool fast enough then blend in some glossy glaze (e.g. G2926B).

Cone 6 Magnesia Matte Base

|

Code # G2934 |

Batch # -2 |

| Materials | Amt | |

|---|---|---|

| Ferro Frit 3124 | 19.400 | 19.01% |

| EP Kaolin | 18.300 | 17.93% |

| Dolomite | 23.500 | 23.03% |

| Silica | 26.960 | 26.42% |

| Calcined Kaolin | 13.900 | 13.62% |

Total:102.06

Auto Unity Formula

|

Si:Al: 6.0:1 5.8 (Molar:5.7) 13.6 |

Notes

This matte recipe was developed from our high-dolomite recipe originally used to compare shipments of dolomite for consistency (but with much higher Al2Oe and SiO2). In our standard firings, this recipe produces both good mattenss and a durable surface coupled with a low chance of crazing on almost any body. This is not a reactive matte, it is intended for functional and durable surfaces. This is also adjustable (the degree of matteness).

WARNING: The degree-of-matteness is very dependent on the cooling rate in the kiln. Fast cooling (e.g. our PLC6DS firing schedule in a lightly-loaded or smaller kiln) produces a silky matte or even glossy surface. Slower cooling (e.g. a heavily loaded kiln or the C6DHSC schedule) may produce a matter surface than you need (more subject to cutlery marking). Control the degree of mattness in three ways:

-Changing the firing curve

-Blending in some glossy G2926B

-Adjusting the recipe to source more SiO2.

This has a very low thermal expansion, meaning it will not craze on just about any clay body. However, on some, it could shiver or lead to glaze compression issues. Use G2934Y2 if this is a problem for you.

https://plainsmanclays.com/g2934 documents this recipe using a variety of stains.

Pictures

Incredible cone 6 speckle body with G2934 matte glazes

This clay, L4115J3S, a Plainsman 3D-based body, fires vitreous and dense, yet there is no hint of bloating. With these matte glazes very durable and functional pieces are produced.

Outside glaze on both is G2934W (adds 10% zircopax). In our C6DHSC firings this produces as matte a surface as is possible without having excessive staining problems. To add a little gloss we blend in 15% of the G2926B Glossy clear.

Inside glazes:

Left mug: L4423A (85:15 mix of G2934 matte/G2926B clear glossy). It does not contain any zircopax.

Right mug: G2926B ball milled glossy, producing a striking visual yet highly functional surface.

These mugs look as close to cone 10R dolomite-glazed ware as we have ever seen! Especially the L4423A recipe

The difference cooling-rate makes

These are the G2934 black glaze at cone 6. The piece on the left was fired using the C6DHSC firing schedule (drop-and-hold at 2100F then 150F/hr to 1400F). The one on the right was fired using the PLC6DS schedule (drop-and-hold at 2100F then free-fall from there). The slow cool gives the glaze on the left time to crystallize, creating a stony matte.

G2934 + 5% Titanium thinner/thicker on M390

G2934 Cone 6 Matte + 4% iron oxide

Left: PLC6DS firing

Right: C6DHSC firing

G1214Z CaO matte vs 2928C MgO matte

Despite being a matte G1214Z is well melted, more than a glossy transparent would be. The development of calcium silicate crystals depends on this high melt fluidity.

The MgO matte on the right (the G2934 recipe made using Ravenscrag Slip) is much less fluid. This also is needed, the viscous melt prevents the surface from flattening during cooling.

This test was not slow cooled.

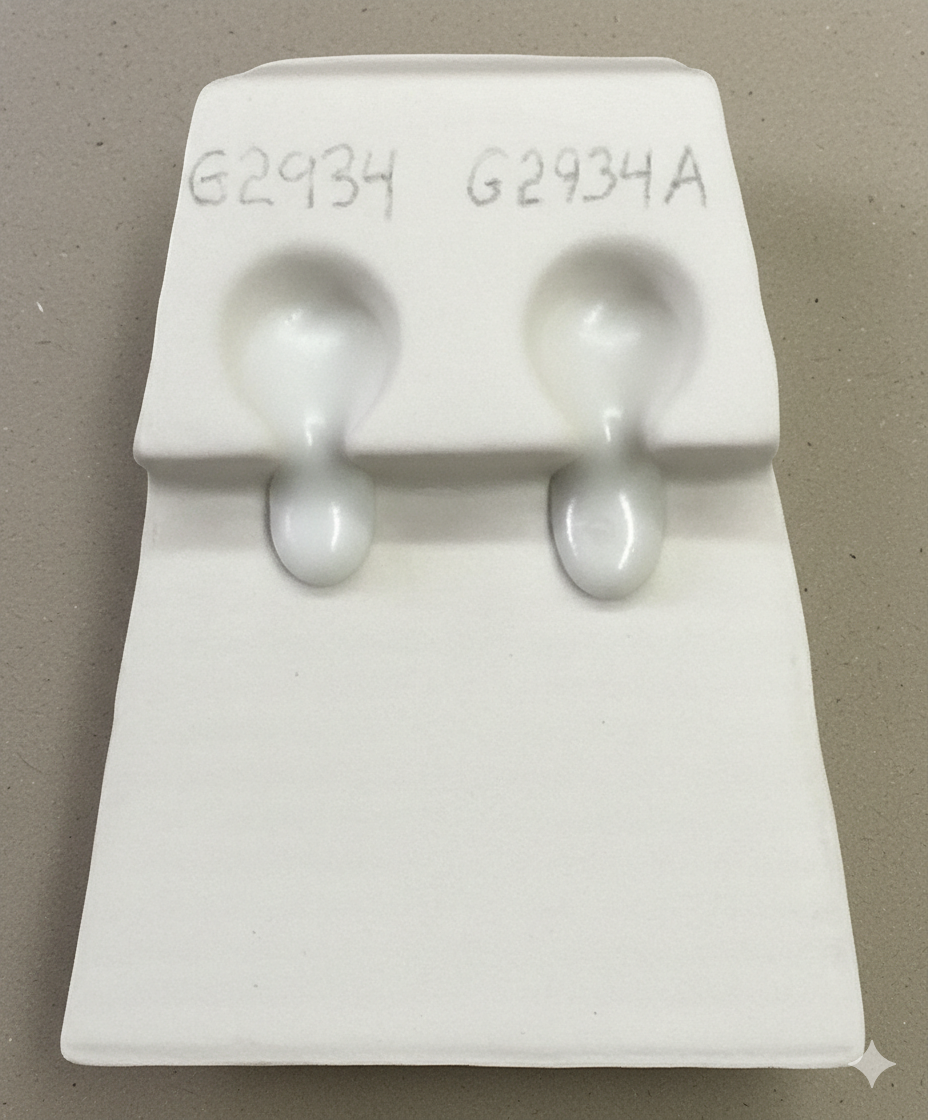

G2934 vs G2934A at cone 6

G2934A is the dolomite testing recipe with added SiO2 (from 2.37 to 3.13) and slightly lower Al2O3.

This has not glossed as expected, the MgO is still working. And it is melting better, unexpected since SiO2 is a refractory oxide. But it appears the reduction in Al2O3 more than made up for the increase in SiO2.

True mattes should still be matte if overfired

GBMF test to compare.

The G2934 is a high-MgO matte, it melts well and does not cutlery mark or stain easily. As evidence that it is a true matte, notice that it is still matte when fired to cone 7 or 8. VC71, while having a similar pleasant silky matte surface at cone 6, converts to a glossy if fired higher (suggesting that its cone 6 matteness is due to incomplete melting). For the same reason the VC71, it is whiter in color (but as soon as it begins to melt and have depth the color darkens).

G2934 with Hemlock Green, Pansy Purle Stains

Cone 6 GBMF tests: 10 gram balls have been melted down onto a tile at cone 6.

Top: G2934 with normal flow.

Left: 8% 6213 Hemlock Green. Needs significant flux.

Right: 8% 6305 Violet stain. Flowing a little less, needs a little flux.

Melt flow comparison: G2934 with Frit 3124, Frit F-19

Fusion Frit F-19 is giving a more fluid melt.

URLs

Prepared public do..om Plainsman Clays

Typecodes

C6-Crawl Cone 6

Alternate Code Number:MG6CDM

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Cone 6 Magnesia Matte Base" id="56852" key="pBmh9ZFj" date="2026-01-15" typecodes="C6" codenum="G2934" picturebasename=""> <recipelines> <recipeline material="Ferro Frit 3124" amount="19.400" tolerance=""/> <recipeline material="EP Kaolin" amount="18.300" tolerance=""/> <recipeline material="Dolomite" amount="23.500" tolerance=""/> <recipeline material="Silica" amount="26.960" tolerance=""/> <recipeline material="Calcined Kaolin" amount="13.900" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2014-03-21, Modified: 2026-01-15 18:53:45

G2934 (lower-LOI)

|

Code # G2934Y |

Batch # -2 |

| Materials | Amt |

|---|---|

| Ferro Frit 3249 | 10.000 |

| EPK | 20.500 |

| Wollastonite | 21.500 |

| Talc | 14.000 |

| Nepheline Syenite | 10.500 |

| Silica | 13.000 |

| Calcined Kaolin | 10.500 |

Total:100.00

Auto Unity Formula

|

Si:Al: 6.1:1 5.8 (Molar:5.6) 3.8 Cost 0.24 per kg |

Notes

This recipe was made as an alternative to blending G2934 matte and G2926B glossy to tune the degree of matteness (this being equal to about an 85:15 mix of those). Those two recipes do not require Frit 3249, they use the much more common 3134, 3124 and 3195. If you are getting started that approach would likely be better for you.

This is an "MgO matte". High MgO content is a common matting mechanism at cone 10 but also works at cone 6. This recipe has the same chemistry as G2934, however, it sources the MgO from a Ferro frit 3249 and talc rather than from dolomite. This specific frit is the secret to why this glaze works. If you do not have it and do not know how to do the chemistry to substitute another MgO-sourcing frit, then you must use the G2934 recipe.

The use of a frit to source MgO in this recipe produces a much lower LOI (3.8 vs. 13.6), a smoother fired surface and better melt fluidity to host stains (stains look fantastic in this base).

Glazes that have MgO levels, including this one, can have crawling issues with certain stains or opacifier additions, especially inside extreme concave contours (e.g. handle joins). Make sure wet glaze slurry wets all inside angles and is not applied too thick. And make sure the glaze dries quickly (glaze inside and outsides separately if needed to avoid water logging the bisque).

WARNING: Like the original, the degree-of-matteness is very dependent on cooling rate. Fast cooling (e.g. free-fall in a lightly loaded or smaller kiln) produces a silky matte surface. Slower cooling (e.g. a heavily loaded kiln) produces a matter and drier surface (subject to cutlery marking). Test in your circumstances to decide whether to adjust your firing to accommodate this or blend in some glossy G2926B produce the silky surface.

Fusion Frit F-69 can be used instead of Ferro Frit 3249 (actually, it is better). This recipe employs a mix of calcined and raw kaolin to keep the drying shrinkage down (to avoid cracking on drying). If you use pure kaolin it will likely crack during drying. If you do not have calcined kaolin just make your own (bisque fire a container of powder).

This glaze has a very low thermal expansion and will not craze on any common clay body. It accepts stains exceptionally well. It is low enough that on some clays it will be under too much glaze compression, this could lead to dunting. Use G2934Y2 if this is an issue.

We recommend doing cutlery marking tests on your ware. If they mark, blend in a little transparent glossy glaze (like G2926B). This will compromise the matteness a little but will reduce the marking.

Again, although matte in appearance, this glaze has a high melt fluidity. That means that brush-on colors could bleed.

Because this contains both calcined and raw kaolins you can adjust their ratios to control the compromise between dry hardness and drying shrinkage. If better gelling response to Epsom salts (or other flocculant) is needed trade one or two percent raw kaolin for bentonite (to increase the particle surface area).

1100 water, 1000 powder to get a creamy mix.

Regular 2934 (with dolomite) took more water, about 1300. Nicer surface than G2934, same matteness, better fluidity.

Mixing notes:

Joe: April 29/19 Mixed up a batch and added 10% Mason #6021 Red stain. Final totals were: G2934Y + 10% stain weighed 5045 grams.

Water weighed 5450 grams.

Let the glaze sit for 3 days to saturate before adding final water to bring to an S.G. of 1.43 and viscosity was approx. 12 seconds with Ford Cup. At these quantities, the final ratios would be:

Glaze powder (including stain) 48%

Water 52%

This mixture yielded about 7.3 litres of mixed glaze. This glaze was screened 80 mesh and has no Epsom salts added.

Pictures

G2934Y plus 8% Cerdec orange stain on Polar Ice, P300

The stain is #239616 encapsulated. The silky surface is stunning. The color is brighter on whiter porcelains.

G2934Y vs. G2934 melt flow balls

10 gram balls were melted down onto these tiles at cone 5.5.

On darker clay bodies the glaze is translucent. For white on this type of clay body a zircopax addition would be needed.

G2934Y vs G2934 melt flow test

The difference is quite amazing. The chemistry is the same. But the MgO is much more readily released from its source materials in the Y version. Also, even thought the melt is more fluid, it is still just as matte. Part of the reason for the extra fluidity could be the much lower entrained micro-bubble population in the Y (these possibly impeding the flow of the dolomite version on the left).

G2934Y matte with Cerdec red, orange stains

8% stain in each. Cone 6. Drop and hold firing. The surface quality is truly stunning!

G2934Y matte on M370 - cup

Surface very pleasant and finer than the standard G2934.

G2934 (left) vs G2934Y (right) at cone 6

G2934Y with brushwork decoration - By Ingeborg Koot

It is not bleeding significantly because the glaze has not been applied too thick.

G2934Y, G2926B, G3806N on L4202

Cone 6, slow cool. Sitting for 3 weeks.

No apparent crazing.

G2934Y, G2926B, G3806N on L4201

Cone 6 slow cool. Sitting for about 3 weeks.

G2926B is crazing.

G2934Y, G2926B, G3806N on L4200

Cone 6 slow cool. Sitting for 3 weeks.

G2926B has crazed.

G2926B, G2934Y on L4199

Cone 6 slow cool. Sitting for 3 weeks.

G2926B has crazed.

G2934Y, G2926B, G3806N on L4198

Cone 6. Slow cool. Sitting for 3 weeks.

G2926B is crazing.

G2934Y, G2926B, G3806N on L4197

Slow cool. Cone 6. Sitting for three weeks.

No apparent crazing.

Typecodes

C6-Crawl Cone 6

Variations

-6600 - Black

16 - Yellow

1680 dry and 1400 water produced SG of 1.44. Pretty thick, added a little darvan. Nov. 22/19: Joe made up a 500 gram batch of this glaze. 500 gms. powder 520 gms. water. S.G. checked 3 days lat

239616 - Orange

Cerdec stain. Required no Epsom salts at 1.43 SG. Joe: Aug.2/18 Made a batch of this glaze: Total Powder 3400 grams Total Water 4000 grams S.G via Viscometer 1.417 Viscosity via Ford Cup 12

4 - Overglaze Blue

Test this as a brush-on color for using over G2934Y. We should demonstrate to customers how to fine tune the melt fluidity of an overglaze color and how to mix it with gum to make it paintable.

6000 - Shell Pink

Joe: Aug.8/18 made a batch using same percentages as when I made a batch of the Orange version on Aug.2/18. Total Powder: 2500 grams Water: 2946 grams. S.G. vis Viscometer was 1.401 Viscosity Ford

6213 - Hemlock Green

A little dark. Very intense. Mixed 110 water to 100 dry (3575/3250) to get 1.43 SG.

6304 - Purple

6364 - Baby Blue

3380 powder, 2800 water. 1.43 SG. Worked perfectly. Joe: I think water and powder quantities should be reversed as below percentages? Joe: July 21/21 Made a 5000 gram batch of base powder and ad

6700 - White

Pink - Mason 6020

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="G2934 (lower-LOI)" id="113976" key="84ZJF8Yb" date="2024-12-16" typecodes="C6" codenum="G2934Y" picturebasename=""> <recipelines> <recipeline material="Ferro Frit 3249" amount="10.000" tolerance=""/> <recipeline material="EPK" amount="20.500" tolerance=""/> <recipeline material="Wollastonite" amount="21.500" tolerance=""/> <recipeline material="Talc" amount="14.000" tolerance=""/> <recipeline material="Nepheline Syenite" amount="10.500" tolerance=""/> <recipeline material="Silica" amount="13.000" tolerance=""/> <recipeline material="Calcined Kaolin" amount="10.500" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2014-03-21, Modified: 2024-12-16 17:03:49

G2934Y (Anti-Crawling)

|

Code # G2934Y1 |

Batch # -2 |

| Materials | Amt | |

|---|---|---|

| Ferro Frit 3249 | 10.000 | 10.10% |

| Nepheline Syenite | 10.500 | 10.61% |

| Wollastonite | 21.500 | 21.72% |

| Talc | 14.000 | 14.14% |

| EPK | 15.000 | 15.15% |

| Silica | 13.000 | 13.13% |

| Calcined Kaolin | 15.000 | 15.15% |

| Additions | ||

|---|---|---|

| CMC Gum | 0.200 | 0.20% |

Total:99.20

Auto Unity Formula

|

Si:Al: 6.1:1 5.7 (Molar:5.6) 3.0 Cost 0.17 per kg |

Notes

Note: For a matte white we are now recommending G3926C (as opposed to adding 10% zircopax to this recipe). G3926C is a mix of G2934 matte and G2926B glossy and combines tin oxide and zircopax to both get a better white than 10% zircopax and have less tendency to crawl. Of course, it is also more expensive, but well worth it to prevent refires.

This change reduces drying shrinkage and increases dry hardness (to prevent crawling). The calcined kaolin is supplying more of the Al2O3 and the raw kaolin less. The overall chemistry remains the same. The glaze will not dry as hard but will shrink less (but the gum will compensate for this).

Increase the gum to as high as can be tolerated (the higher the percentage used the slower the glaze will dry and the more dripping will occur, but it will dry harder and bond better with the bisque). Sufficient gum will completely eliminate cracking (and therefore crawling).

Pictures

Typecodes

C6-Crawl Cone 6

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="G2934Y (Anti-Crawling)" id="156653" key="JcoQHGcp" date="2022-07-27" typecodes="C6" codenum="G2934Y1" picturebasename=""> <recipelines> <recipeline material="Ferro Frit 3249" amount="10.000" tolerance=""/> <recipeline material="Nepheline Syenite" amount="10.500" tolerance=""/> <recipeline material="Wollastonite" amount="21.500" tolerance=""/> <recipeline material="Talc" amount="14.000" tolerance=""/> <recipeline material="EPK" amount="15.000" tolerance=""/> <recipeline material="Silica" amount="13.000" tolerance=""/> <recipeline material="Calcined Kaolin" amount="15.000" tolerance=""/> <recipeline material="CMC Gum" amount="0.200" added="true"/> </recipelines> </recipe> </recipes>

Born: 2014-03-21, Modified: 2022-07-27 10:49:34

G2934Y (Higher COE/Stony)

|

Code # G2934Y2 |

Batch # -2 |

| Materials | Amt |

|---|---|

| Fusion Frit F-69 | 7.500 |

| Ferro Frit 3110 | 21.000 |

| Wollastonite | 15.000 |

| Talc | 14.500 |

| EPK | 20.000 |

| Silica | 7.000 |

| Calcined Kaolin | 15.000 |

Total:100.00

Auto Unity Formula

|

Si:Al: 6.3:1 6.3 (Molar:6.1) 3.7 Cost 0.23 per kg |

Notes

The G2934 and G2934Y have very low thermal expansions. That is good to prevent crazing but it can cause shivering and even glaze compression/dunting for some bodies. This version increases KNaO (sourcing it from Ferro Frit 3110) at the expense of CaO.

This change has the additional effect of making the matte surface physically smoother and more bone-like. It does cutlery mark somewhat, but is quite striking.

The Fusion Frit F-69 is the very similar chemistry as Ferro Frit 3249.

Pictures

Very smooth yet stony matte G2934Y2 Cone 6

Cutlery marks but almost cleanable. On M370.

Surface porcelain like, almost invisible on ware are first glance.

G2934Y2 matte on outside of polar ice piece

Typecodes

C6-Crawl Cone 6

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="G2934Y (Higher COE/Stony)" id="143110" key="NbiMsRGS" date="2024-12-16" typecodes="C6" codenum="G2934Y2" picturebasename=""> <recipelines> <recipeline material="Fusion Frit F-69" amount="7.500" tolerance=""/> <recipeline material="Ferro Frit 3110" amount="21.000" tolerance=""/> <recipeline material="Wollastonite" amount="15.000" tolerance=""/> <recipeline material="Talc" amount="14.500" tolerance=""/> <recipeline material="EPK" amount="20.000" tolerance=""/> <recipeline material="Silica" amount="7.000" tolerance=""/> <recipeline material="Calcined Kaolin" amount="15.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2014-03-21, Modified: 2024-12-16 05:30:38

G2934 Super Durable

|

Code # G2934Y3 |

Batch # -2 |

| Materials | Amt | |

|---|---|---|

| Nepheline Syenite | 5.400 | 5.39% |

| Wollastonite | 17.900 | 17.88% |

| Talc | 17.900 | 17.88% |

| EPK | 12.100 | 12.09% |

| Silica | 25.300 | 25.27% |

| Calcined Alumina | 10.600 | 10.59% |

| Ferro Frit 3134 | 10.900 | 10.89% |

Total:100.10

Auto Unity Formula

|

Si:Al: 6.1:1 5.9 (Molar:5.8) 2.7 Cost 0.14 per kg |

Notes

A customer, who makes floor tiles, wanted more durability so he did research finding that industrial tile technicians supply some of the Al2O3 from calcined alpha alumina to add durability to a glaze. The surface has stayed almost the same as G2934Y. And it still has the same chemistry as G2934.

We added 2g of VeeGum T per 1000g of dry glaze.

Pictures

G2934Y3 on M340, M390, Coffee

Surface is smoother, very nice.

Well melted. Not cutlery marking.

G2934H vs. G2934Y3 Melt Fluidity

Firing was not held at cone 6, but dropped and held at 2100F for 30 minutes. It does not seem logical that this mouth would be able to take that much powdered alumina into solution, but clearly this one is melting very well. Our alumina is very fine grained at least 325 mesh, that is likely important.

G2934Y3/Y4 mix with 10% Mason 6600

More matte than usual, but very striking. Cutlery marks. Needs some glossy glaze added.

Typecodes

C6-Crawl Cone 6

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="G2934 Super Durable" id="155345" key="8PoDbMyg" date="2019-09-27" typecodes="C6" codenum="G2934Y3" email="zeega.tomc@gmail.com" picturebasename=""> <recipelines> <recipeline material="Nepheline Syenite" amount="5.400" tolerance=""/> <recipeline material="Wollastonite" amount="17.900" tolerance=""/> <recipeline material="Talc" amount="17.900" tolerance=""/> <recipeline material="EPK" amount="12.100" tolerance=""/> <recipeline material="Silica" amount="25.300" tolerance=""/> <recipeline material="Calcined Alumina" amount="10.600" tolerance=""/> <recipeline material="Ferro Frit 3134" amount="10.900" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2014-03-21, Modified: 2019-09-27 16:15:17

G2934 Super Durable #2

|

Code # G2934Y4 |

Batch # -2 |

| Materials | Amt |

|---|---|

| Ferro Frit 3110 | 9.000 |

| Wollastonite | 21.000 |

| *Silverline Talc | 14.000 |

| Bentonite | 2.000 |

| Silica | 23.000 |

| Calcined Alumina | 10.000 |

| EPK | 12.000 |

| Ferro Frit 3249 | 9.000 |

Total:100.00

Auto Unity Formula

|

Si:Al: 5.2:1 6.2 (Molar:6.2) 2.0 Cost 0.14 per kg |

Notes

This sources much of the Al2O3 from calcined alumina. While not intuitive (it should not melt as well as sourcing it from kaolin), this is apparently a common practice in the ceramic tile industry. And this recipe is in use for exactly that.

Pictures

G2934Y4 melt fluidity test

Not held at cone 6, but dropped 100F and held for 30 minutes. Compared to G2934 (which is not running as well as usual). This one, on the right, looks identical to Y3. That means the frit:talc combo is not really melting it any better than the talc alone did.

G2934Y4 on M370, M390 fired cone 6

Stunning silky matte surface of very fine texture.

G2934 (left) vs G2934Y4 on M370

They look almost the same. Cone 6. Slow cool firing.

G2934 (left) vs. G2934Y4

Cone 6 on M390, M340, Coffee Clay

G2934Y4 on a range of american pottery clays

Fired cone 6. Bodies from Standard, Sheffield, Laguna.

Typecodes

C6-Crawl Cone 6

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="G2934 Super Durable #2" id="159276" key="EH3wGYtL" date="2025-11-05" typecodes="C6" codenum="G2934Y4" email="zeega.tomc@gmail.com" picturebasename=""> <recipelines> <recipeline material="Ferro Frit 3110" amount="9.000" tolerance=""/> <recipeline material="Wollastonite" amount="21.000" tolerance=""/> <recipeline material="Silverline Talc" amount="14.000" tolerance=""/> <recipeline material="Bentonite" amount="2.000" tolerance=""/> <recipeline material="Silica" amount="23.000" tolerance=""/> <recipeline material="Calcined Alumina" amount="10.000" tolerance=""/> <recipeline material="EPK" amount="12.000" tolerance=""/> <recipeline material="Ferro Frit 3249" amount="9.000"/> </recipelines> </recipe> </recipes>

Born: 2014-03-21, Modified: 2025-11-05 17:41:24