Project Name

Gerstley Borate Transparent Glossy Base Glaze Recipes

Project Codenumber

UnAssigned

Notes

Gerstley Borate was found in amounts up to 50% of the total recipe, creating very fluid base glazes (at both low and middle temperatures). Depending on the amount of feldspar present, recipes had from 5-20% kaolin (the two together supplying the needed Al2O3). Silica was almost always present, typically 20-30%.

These recipes are intended as example of base clear recipes (although some show pigment and variegator additions).

GB by itself melted well even at cone 06. So, as you can imagine, recipes having 50% would have a very fluid melt at cone 6. No wonder some reactive visual effects were achieved (e.g. variegation, crystallization, varying degrees of milkiness, boron blue and opacity according to thickness). Additions of rutile (for yellowish and brown colors) and titanium. Being fluid transparent it could support significant amounts of iron and yet still be quite light in color.

The melt fluidity was also a benefit in that darkly colored overglazes feather into lighter colored matte surfaces. Of course this is an issue with underlglaze decoration. And there are solubility and hardness issues with very high boron.

While many people believe that Gerstley Borate is the key to the variegation of glazes, this is not true. The visual character was most often because of titanium, rutile and lithium additions into an already very fluid-melt high-boron base. Fritted transparents can also be fluid-melt and they can host these same additions and produce variegation also.

Low percentages of kaolin (EPK) can be remedied by sourcing KNaO from Ferro Frit 3110 (instead of feldspar or nepheline syenite). That will produce a slurry that does not have issues with gelling (the way GB slurries did).

50:30:20 Gerstley Borate Cone 6 base

|

Code # G2826A |

Batch # -2 |

| Materials | Amt |

|---|---|

| Gerstley Borate | 50.000 |

| EPK | 20.000 |

| Silica | 30.000 |

Total:100.00

Auto Unity Formula

|

Si:Al: 9.9:1 6.0 (Molar:6.1) 17.7 Cost 0.23 per kg |

Notes

This is recipe has been around for a long time. It is the base for many others, mainly because of its high melt fluidity (e.g. Butterscotch (Rust) added: 4% rutile, 4% tin oxide and 1% lithium carboante.

This fires with plenty of boron blue and bubble clouding, but that was seen as part of the aesthetic. It has a low thermal expansion and fitted most clay bodies.

Mixing this 50:50 with water produces 1.44 specific gravity, but it will be pure gel. Adding 0.5% Darvan helps to thin it for long enough to dip bisque samples (but the glaze goes on very thin). The slurry re-gels within seconds.

For making flow tester balls this slurry dewaters very slowly on a plaster bat.

GB is a clay, capable of suspending and dry hardening a glaze at only 25% concentration. Yet this has double that plus adds kaolin which would further increase drying shrinkage! It is amazing that it was even possible to make a usable slurry out of this!

Pictures

G2826A vs G2826A1 low test

A1 supplies boron using frit 3134.

Since the frit contains less boron the full B2O3 cannot be supplied and it has a little more Al2O3 and SiO2.

But the A1 has 6 times lower LOI.

G2826A is a good recipe for comparing GB substitutes.

G2826A Gerstley Borate 50:30:20 base as jelly

G2826A on M390 - lots of boron blue

You might think this looks nice. But it comes at a cost (bubbling, jelling, running, cracking on drying, crawling). Boron blue is considered a glaze fault.

That being said, many people like gerstley borate for this very reason.

Fired at 1700F G2826A 50:30:20 GB

Fired at 1700F

G2826A 50:30:20 GB

G2826A1 same chem using frit

G2826A2 50:30:20 using Gill Borate (should be crawling??)

G2826A3 50:30:20 makeover using GillBor

G2826A3-2 same but with calcine kaolin

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="50:30:20 Gerstley Borate Cone 6 base" id="67237" key="ewNL1whH" date="2024-10-02" codenum="G2826A" picturebasename=""> <recipelines> <recipeline material="Gerstley Borate" amount="50.000" tolerance=""/> <recipeline material="EPK" amount="20.000" tolerance=""/> <recipeline material="Silica" amount="30.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2000-04-18, Modified: 2024-10-02 18:51:28

50:30:20 Frit 3134 base (fixed)

|

Code # G2826A1 |

Batch # -2 |

| Materials | Amt |

|---|---|

| Ferro Frit 3134 | 29.000 |

| EPK | 19.000 |

| Fusion Frit F-69 | 20.000 |

| 325 mesh silica (Silica) | 22.000 |

| Wollastonite | 10.000 |

Total:100.00

Auto Unity Formula

|

Si:Al: 9.7:1 6.0 (Molar:6.1) 2.8 Cost 0.22 per kg |

Notes

The 77C04E base (50:30:20 Frit 3134:silica:kaolin) has multiple issues as an alternative to the original 50:30:20 Gerstley Borate G2826A recipe. This addresses those.

The boron here is less that G2826A, this is as much as common frits will supply - however, this amount produces fewer bubbles, better durability, much less boron blue. The MgO is a little higher, this helps keep the thermal expansion down.

100:80 powder:water mix produces a specific gravity of 1.53, a creamy slurry that applies perfectly. But it would likely be better with more water and Epsom salts (to create a thixotropic slurry).

Of course, this produces a more sterile looking glaze, without the variegation and boron blue. But variegation can be restored with the addition of 1-4% titanium dioxide, it produces a cloudiness that looks better than boron blue. Colorants can then be added to that. Rutile, an impure form of titanium, could also be used, it can both stain and variegate the fired glass.

Pictures

G2826A vs A1 50:30:20 base flow test

The flow of the fritted version (on the right) has no boron-blue, more surface tension, less LOI disruption. Fluidity is only a little less even though this has less boron.

G2826A, G2826A1 on M340, M370

Boron blue gone on the fritted version.

Of course, if you want this effect it can be achieved by increasing the amount of B2O3 in the formula.

G2826A vs G2826A1 demos Gerstley Borate vs Frits to source boron

If a better quality functional glaze is needed then the G2826A1 fritted version on the right is much better. That being said, many people seek the visual character of the one on the left. Perhaps a mix of the two could reduce some of the working and technical issues with the G2826A version.

G2826A vs G2826A1 low test

A1 supplies boron using frit 3134.

Since the frit contains less boron the full B2O3 cannot be supplied and it has a little more Al2O3 and SiO2.

But the A1 has 6 times lower LOI.

G2826A is a good recipe for comparing GB substitutes.

G2826A3 vs G2826A1 - Fired to 1700F

The G2826A1 employs a frit, the G2826A2 (left) Gillespie Borate.

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="50:30:20 Frit 3134 base (fixed)" id="223705" key="YwqJRBmy" date="2023-09-08" codenum="G2826A1" picturebasename=""> <recipelines> <recipeline material="Ferro Frit 3134" amount="29.000" tolerance=""/> <recipeline material="EPK" amount="19.000" tolerance=""/> <recipeline material="Fusion Frit F-69" amount="20.000" tolerance=""/> <recipeline material="325 mesh silica" lookup="Silica" amount="22.000" tolerance=""/> <recipeline material="Wollastonite" amount="10.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2000-04-18, Modified: 2023-09-08 03:23:36

Worthington Cone 06-2 Clear

Gelling, High LOI, Gerstley Borate difficult to sub, High Boron

|

Code # G2931 |

Batch # -2 |

| Materials | Amt |

|---|---|

| Gerstley Borate | 55.000 |

| EPK | 30.000 |

| Silica | 15.000 |

Total:100.00

Auto Unity Formula

|

Si:Al: 5.3:1 6.5 (Molar:6.6) 20.7 Cost 0.34 per kg |

Notes

This recipe is a common Gerstley Borate clear base used from 04 all the way to cone 6! At higher temperatures the recipe trends toward less kaolin to more silica and a little less GB (e.g. 50:20:30).

Attractions its simple make-up and crystal clear fired result (low bubble population). Although it can also fire with clouding, variegation and boron blue depending on thickness, the clay body and firing.

The high boron content of Gerstley Borate, enabling high melt fluidity, make this glaze possible. Potters use it on terra cotta, talc and stoneware bodies that generate lots of gases of decomposition and this can often pass and heal bubbles well. High boron clear glazes like this are known for clouding issues (because of micro bubbles) but this has a low enough surface tension to pass them.

Problems with this recipe:

Obviously, if it melts well already at cone 04 great care is going to be needed at cone 2 to prevent it running onto shelves. Highly melt fluid glazes (that have high boron like this) are also more likely to be leachable and to crystallize on cooling (producing the boron-blue clouds).

Paramount is the dreadful problem of gelling. Even with only 1.4 specific gravity (about equal weights of dry material and water and deflocculation with Darvan) it gels badly. The high water content needed and the nature of GB means that glazed ware dries extremely slowly, the glaze shrinks and cracks during drying and crawls during firing. Gerstley Borate is very plastic, yet to make matters worse, the recipe has an additional 30% clay on top of that! This recipe can actually be thrown on a potters wheel!

The thermal expansion is too low for talc bodies, it will shiver on them.

Pictures

Worthinton Clear at cone 01

On a terra cotta clay at this temperature was has stoneware properties. The fired surface is good.

Worthington Clear vs. Fritted Clear

Worthington (right) flows even better than the fritted glaze and does not have any more entrained bubbles even though it has an LOI of 20%. This is likely because its melting history and behavior is such that its ability handle gases of decomposition from the body and its own materials is so much better.

2931 vs 2931b

On Plainsman L215 cone 02 the original base Worthington Clear has gone on very thin on sides of mug (because of the low specific gravity necessary to prevent it from gelling it is very difficult to get it on thick enough). The fired surface is clear but not as glossy. On the rim it has bubbles. The Ulexite version (G2931B) is glossier, and went on thicker because the slurry is so much easier to use. This glaze is not recommend for L215, the latter contains talc that increases its thermal expansion, putting too much squeeze on this glaze.

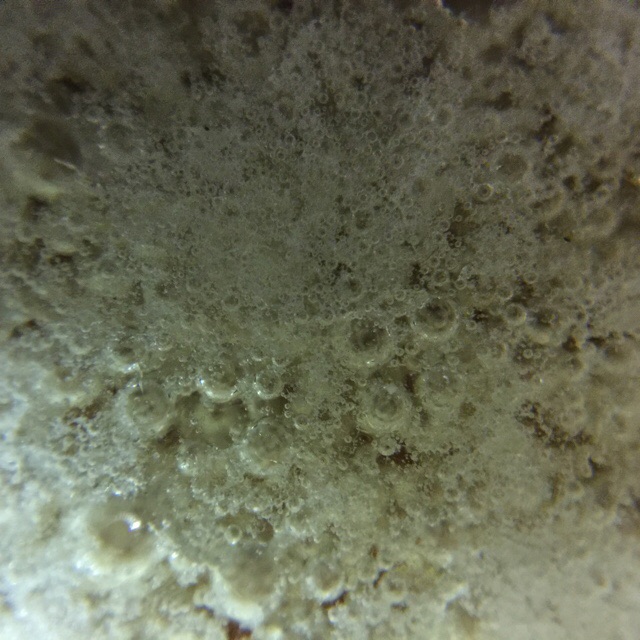

Entrained bubbles in Worthington Clear

This is a 16X closeup of flow test (10 gram ball melted down onto a tile) that concentrates bubbles. There are high populations of large and tiny ones. The larger ones are from the Gerstley Borate, the tiny ones from the kaolin.

GB vs Ulexite Clear glaze bubbles

These are 10 gram balls fired down onto tiles at cone 04 to compare melt fluidity and bubble populations in three clear glazes. Larger bubbles are better, they break at the glaze surface and heal. Tiny ones produce cloudiness.

Left: The original Worthington fluid melt clear glaze recipe. There are clusters of tiny bubbles and many large.

Center: A glaze of the same chemistry but sourcing its boron from Ulexite instead. Notice the lack of tiny bubbles. This fires pretty well identical to the original but has much better slurry properties.

Right: Center with with a 10% addition of lead bisilicate frit. This fires more glossy than either of the other two. Its thermal expansion is also likely lower.

Worthington Clear the next day

Even though this has a low specific gravity and is deflocculated with darvan, the next day it is still jelly. Impossible to use unless more Darvan is added, who knows where that will go!

G2922G, G2931 flow tests

Testdata

SHAB - Shrinkage/Absorption

| DLEN | DSHR | FSHR | ABS | |

| 1 | 92.24 | 7.8% | ||

| 2 | 92.11 | 7.9% |

LDW - LOI/Density/Water Content

| WWGT | DWGT | H2O | LOI | DENS | |

| 1 | 13.52 | 10.26 | 24.1% |

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Worthington Cone 06-2 Clear" keywords="Gelling, High LOI, Gerstley Borate difficult to sub, High Boron" id="56711" key="trnR5FfW" date="2025-04-06" codenum="G2931" picturebasename=""> <recipelines> <recipeline material="Gerstley Borate" amount="55.000" tolerance=""/> <recipeline material="EPK" amount="30.000" tolerance=""/> <recipeline material="Silica" amount="15.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2014-03-17, Modified: 2025-04-06 20:26:29

Zero3 K Cone 03 Transparent Glaze

|

Code # G2931K |

Batch # -2 |

| Materials | Amt | |

|---|---|---|

| Ferro Frit 3195 | 25.000 | 26.32% |

| Ferro Frit 3134 | 33.000 | 34.74% |

| EPK | 20.000 | 21.05% |

| Ferro Frit 3249 | 10.000 | 10.53% |

| Ferro Frit 3110 | 7.000 | 7.37% |

Total:95.00

Auto Unity Formula

|

Si:Al: 6.1:1 7.4 (Molar:7.5) 3.1 Cost 0.24 per kg |

Notes

This recipe improved on the popular Worthington Gerstley-Borate-based low fire clear recipe. It targeted cone 03 to work best on Zero3 stoneware and porcelain. To fire lower (cone 06-04), consider G1916Q (or derivatives) instead.

Unlike its Worthington Clear predecessor, this does not become a bucket of jelly, does not crack on drying, does not go on unevenly or the wrong thickness, does not cloud up with boron blue or micro-bubbles when fired (because it has lower CaO) when used on the types of bodies discussed below. It is crystal clear and super glassy at cone 03.

If you liked the variegated appearance of the GB version, titanium dioxide can be added to this to produce even better variegation. For darker color rutile with do the same.

Low fire bodies span a wide range of thermal expansions. While Worthington clear (an ancestor of this recipe) melts to a good clear, its thermal expansion was too low. This recipe, G2931K, raises thermal expansion (by adding Na2O). The thermal expansion of Zero3 stoneware and porcelain are about the middle of the range, and they develop good glaze:glaze interfaces, so this recipe fits them well.

This glaze shivers on high-talc bodies and can craze on zero-talc porous ones. This recipe has three variations we have worked with, one of higher expansion (G2931H) and one of lower expansion (G2931L). Keep in mind that adding zircon and stains changes expansion.

Dipping ware in Zero3 Transparent is just so much easier than trying to paint on commercial, slow-drying clears. For us it naturally gels to a creamy consistency at around 1.53 specific gravity (in our circumstances). However it goes on too thick at that high a value, we have found the best all-around performance at 1.43 with enough Epsom Salts to gel it back up to a creamy thixotropic consistency (a few grams per gallon).

Pay special attention to the drop-and-hold firing schedule, especially if your clay body is not fine-grained. Use 04DSDH as a model.

To mix up 5 Kg use about 4.5 kg of water to get 6.5 litres of dipping glaze. To make a brushing glaze: For each 100g of powder mix start with 125 water, 1.5 CMC gum and 1.5 Veegum and thoroughly mix in a kitchen blender (add water if it gels too much). We find the about 330g of powder produces a 500ml (about 1 pint) jar.

To make colored versions add stains as needed (if stains cause micro-bubbling or orange peel surface include 2-3% zircopax).

Batch Ticket Notes

These notes were entered in the notes panel under "Batch Ticket Notes"

Pictures

G2931K on Zero3 Stoneware

Fired cone 03. Body is Zero3 stoneware.

Surface is perfect, even where thick. Ultra clear.

Survived three boil:ice cycles and one 300F:ice cycle without crazing.

G2931F vs. G2931K on Polar Ice Low Fire

2931F was the Ulexite flused version of this recipe. The F survived three boil:ice cycles and 1 300F:ice cycle without crazing or shivering.

The K is slightly smoother, tiny dimples in the surface are fewer. It is also applied thicker.

G2931F vs G2931K fritted - terra cotta mugs cone 03

F was the Ulexite-fluxed version of this recipe.

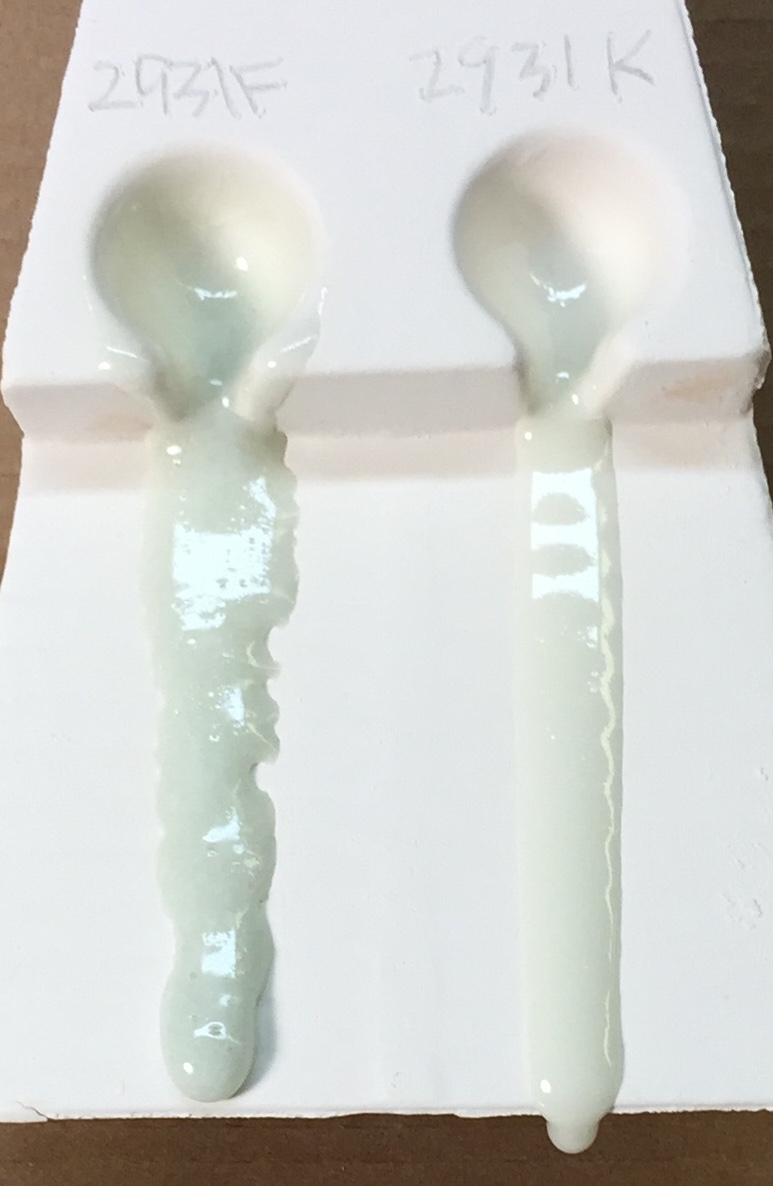

G2931F vs G2931K flow test

These two recipes have the same chemistry, but K sources boron from frits rather than Ulexite. Notice how much less bubbles there are in the flow and how much more predictable the melting pattern is.

G2931F vs G2931K - Melted balls at cone 03

F, the Ulexite version, is obviously bubbling more, the percolation is causing the melt to spread out more on the tile. On the flow test is was less fluid.

Firing temperature is important for Zero3 glaze

This is G2931F on Plainsman Buffstone, L213, F100, L215. First column is cone 04, center is cone 03, right is cone 02. All exited the kiln without crazing except Buffstone at cone 04.

We subjected all of them to a 300F:IceWater thermal shock.

Buffstone crazed on all of them.

L215 and L212 Cone 04 crazed.

L213 was good but later the glaze was found to be under excessive compression, subject to shivering over underglazes.

At cone 02 there are some dimples and defects.

Three low fire bodies that need three clear glazes

Because of glaze fit. Left: Plainsman Buffstone, contains no talc, fires buff. Center: L212 (about 25% talc). Right: L213 (about 45% talc, fires whiter). Talc raises thermal expansion. The centre glaze is G2931K (Insight-live reports COE 7.4), it fits L215 (also Zero3 porcelain and stoneware). It crazes on Buffstone and shivers on L213 and L212. G2931L has lower expansion (to work on zero-talc porous bodies). G2931H is higher (for talc bodies like L213).

G2931K glaze precipitates things on storage

G2931K On L212 after a year

Some crazing starting.

K on L215 at cone 04

The thicker version is clouding. The thinner one has micro-pinholes. It needs a higher temperature.

G2931K o L215 - Cone 03, thick application

G2931K on L215 - Cone 03 fired in 30 minutes

Very transparent. No crazingafter many months.

G2931K on L215 - Cone 06

Milky (because cone 06 is underfired for this glaze). But only a little crazing after a year.

G2931K running on Zero3 Casting

This happened at cone 03 and 04. The G3879 (left) did not run. For some reason G2931K easy applies to thickly on this body.

This 1000 gram batch of glaze powde

This 1000 gram batch of glaze powder screened 80 mesh immediately after making, and allowed to sit for 3 months prior to usage.

The material in photo was screened out once again after the 3 month time lapse, (80 mesh once again).

The largest balls are approx. 2.5 mm. in diameter, and when these particles were screened out, and still perhaps slightly wet?, they were quite easy to break in half with your fingernail.

G1916Q (left) vs G2931K (right) at cone 04

On a terra cotta body, the G1916Q is performing better, there are less micro bubbles.

URLs

How to tune the thixotropy of a glaze

How to convert a d..o a brushing glaze

Typecodes

ST-Untitled typecode

Alternate Code Number:GS04-1

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Zero3 K Cone 03 Transparent Glaze" id="95671" key="MowxZiNQ" date="2023-05-03" typecodes="ST" codenum="G2931K" picturebasename=""> <recipelines> <recipeline material="Ferro Frit 3195" amount="25.000" tolerance=""/> <recipeline material="Ferro Frit 3134" amount="33.000" tolerance=""/> <recipeline material="EPK" amount="20.000" tolerance=""/> <recipeline material="Ferro Frit 3249" amount="10.000" tolerance=""/> <recipeline material="Ferro Frit 3110" amount="7.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2006-03-16, Modified: 2023-05-03 20:54:14