Project Name

High Melt Fluidity Cone 6 Clear Glaze

Project Codenumber

UnAssigned

Notes

This project is about finding a fluid melt base glaze recipe that has a low enough thermal expansion to fit as many bodies as possible.

Most functional ceramic glazes can be distilled down to two parts: a clear matte or glossy base plus opacifiers and colorants. It is always best to use a base having plenty of SiO2 and Al2O3 to produce a glass that is resistant to leaching and wear. G2926B is an excellent example, it produces a glassy smooth and durable glaze. We use it whenever possible. However for reactive visual effects, a fluid melt base is needed and that means sacrificing some Al2O3/SiO2 (and the associated durability).

The low viscosity (and higher melt fluidity) of such base glazes enable freer molecular movement to create crystals. They form multiple glass phases having different viscosities, when color or opacity is present they create rivulets and streaking as they run. Fluid melts also produce brilliant effects with certain colors that would otherwise matte a functional base (copper blue is an example). But fluid melt base recipes normally come at another cost: they craze more. This is because fluxing oxides that produce gloss have much higher thermal expansion than Al2O3 and SiO2 and fluid melt glazes have high flux content. Stoneware bodies are normally not difficult to fit glazes to but porcelains, especially those with lower silica and higher kaolin contents, are much more difficult.

Fluid melt glazes do also have advantages. They pass bubbles better, producing a more crystal clear glass. They also excel at transmitting the color of underglazes (albeit smudging them more).

I have included the G3948A recipe here because it is so fluid yet has a low thermal expansion. Of course, you need to drop the iron oxide to call it a "base recipe" (then add other colorants).

Campana Cone 6 Transparent Glaze

3134, Spodumene, Zinc

|

Code # G3813 |

Batch # -2 |

| Materials | Amt |

|---|---|

| Spodumene | 11.000 |

| Ferro Frit 3134 | 21.000 |

| EP Kaolin | 20.000 |

| Silica | 20.000 |

| Wollastonite | 20.000 |

| Zinc Oxide | 8.000 |

Total:100.00

Auto Unity Formula

|

Si:Al: 8.7:1 6.7 (Molar:6.8) 3.0 |

Notes

This is a popular fluid-melt cone 6 base recipe. We first compared it with 4 others in an effort to produce a fluid-melt, super-gloss, low-expansion transparent base. This appears to be the 20x5 recipe with Custer feldspar switched for a mix of zinc and spodumene (combining the power of lithia, zinc and boron fluxes to achieve a very low calculated thermal expansion, it does not craze on any of the bodies tested). Interestingly, because it has lots of melt fluidity it could likely accept more Al2O3 and SiO2 and yet still fire glossy (meaning the expansion could be taken still lower).

The bubble population is a concern.

Equal weights of water and powder creates about 1.47 SG. To get it to 1.45 SG thus requires more water than powder. It creates alot of bubbles in the slurry itself (from the Spodumene, wash it first to reduce these). The powder resists wetting. It responds quickly to vinegar.

We ended up choosing the Panama base over this one because of the higher bubble population in the melt and the issues that Spodumene creates with the slurry. But if you need a lower thermal expansion (the G3806C crazes on your clay body), then this one is worth trying.

Pictures

Compared with G2926B

These are 10 gram balls melted down onto a tile to demonstrate fluidity, clarity and bubbling.

Left is our standard cone 6 glaze.

Right: G2813.

It is flowing significant more, but not as much more as some others I am testing right now.

Bottom: G3813 on a Polar Ice porcelain tile. It is high glossy, not crazing out of the kiln.

G3813 16x closeup of entrained bubbles

Others also had bubbles, but there are alot here. And they are all the same size (in clouds). Although the photo does not show it clearly, hundreds of these are breaking at the surface, leaving dimples. This was fired by drop-100F-an-soak. This would do better in clearing itself with thinner application.

G3814 Low Zinc High Feldspar Fritless base melt balls

Top: G3814

G2926B Plainsman whiteware base

L3808A high B2O3 fluid clear

G3813 Campana clear

Fluid cone 6 clear glazes

These are 10 gram glaze balls are fired down onto tiles to demonstrate melt fluidity and bubbling.

Left: L3808 GB clear from Shaun Mollonga (most fluid).

G3808A fritted recalculation of former (best surface).

G3813 Campana clear (most transparent).

G3806B Panama Blue base.

All of these survived 260F:Icewater test without crazing on M370, M390 and M340.

Campana Clear is the smoothest on M340, Panama is second best.

Campana clear on Plainsman M370,340,390

These were ice water tested at 260F and did not craze. Coverage is defect free on all three clays.

Fluid cone 6 clear glaze comparison

Top are 10 gram balls melted down onto a tile to demonstrate melt fluidity and bubble populations.

Second row: Plainsman M370 whiteware

Third row: Plainsman M340 buff stoneware

Fourth row: Plainsman M390 red stoneware

Left to right:

G3814 - not melting as well

G2938 - Water blue base

G3808 - High Gerstley Borate base

G3808A - 3808 using frits instead

G3813 - Campana base

G3806B - Panama base

Cone 6 High Fluid Melt Transparents

The chemistry of these glazes falls outside typical cone 6 boron, soda, calcia, magnesia chemistry. Why? To achieve higher melt fluidity for a more brilliant surface and for more reactive response with colorant and variegator additions. Classified by most active fluxes they are:

G3814 - Moderate zinc, no boron

G2938 - High-soda+lithia+strontium

G3808 - High boron+soda (Gerstley Borate based)

G3808A - 3808 chemistry sourced from frits

G3813 - Boron+zinc+lithia

G3806B - Soda+zinc+strontium+boron (mixed oxide effect)

Compare four clear bases for copper blue

Has extenal picture also

The flow testers at the back and the melt-down-balls in from of them have 1% copper carbonate. The glazed samples in the front row have 2% copper carbonate. L3806B, an improvement on the Panama Blue recipe, has the best color and the best compromize of flow and bubble clearing ability.

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Campana Cone 6 Transparent Glaze" keywords="3134, Spodumene, Zinc" id="75226" key="5d4McWuW" date="2018-03-19" codenum="G3813" email="strawdogs@hotmail.com"> <recipelines> <recipeline material="Spodumene" amount="11.000" tolerance=""/> <recipeline material="Ferro Frit 3134" amount="21.000" tolerance=""/> <recipeline material="EP Kaolin" amount="20.000" tolerance=""/> <recipeline material="Silica" amount="20.000" tolerance=""/> <recipeline material="Wollastonite" amount="20.000" tolerance=""/> <recipeline material="Zinc Oxide" amount="8.000" tolerance=""/> </recipelines> </recipe> </recipes>

Born: 2015-06-23, Modified: 2018-03-19 15:58:30

Panama Cone 6 Adjustment 2015

High fluid melt glaze for reactive effects and super gloss colors

|

Code # G3806C |

Batch # -2 |

| P | Materials | Amt | |

|---|---|---|---|

| Silica | 26.300 | 26.27% | |

| Kaolin | 19.700 | 19.68% | |

| Dolomite | 8.700 | 8.69% | |

| Strontium Carbonate | 4.400 | 4.40% | |

| Ferro Frit 3110 | 31.100 | 31.07% | |

| Ferro Frit 3134 | 6.600 | 6.59% | |

| Zinc Oxide | 3.300 | 3.30% |

| P | Additions | ||

|---|---|---|---|

| * | Copper Oxide | 2.000 | 2.00% |

| * | Tin Oxide | 2.500 | 2.50% |

Total:104.60

Auto Unity Formula

|

Si:Al: 11.1:1 7.3 (Molar:7.1) 7.9 |

Notes

This is work I did in 2015 (in 2019 a much bigger project developed this further).

The copper and tin produce the turquoise celadon effect.

This recipe is for a brilliant fluid-melt transparent base glaze, initially for copper blues and greens, but later for stains. "Fluid-melt" means it runs down off ware if applied too thickly, this is a key for achieving many visual effects.

Initiailly I compared a number of recipes I found on line and finally selected Panama Blue. I removed the colorants and made adjustments to improve slurry properties and lower the thermal expansion (it has serious crazing issues). Fluid-melts have a down side: Crazing is an issue (because the fluid melt requires more fluxes, these have higher thermal expansions).

Then I did three adjustments, each lowering the thermal expansion more than the last. While keeping the same brilliant visual appearance. The recipe ended up being quite different (two materials were eliminated from the recipe, their oxides supplied by the others). The chemistry of this one moves much of the KNaO to low-expansion MgO. This makes it melt a little less, but visually it is the same. Higher ZnO helps melting (since MgO is not nearly as powerful a flux as KNaO). I was even able to add extra SiO2. The calculated thermal expansion has gone from 7.7 down to 7.3.

This worked well on stonewares but still crazed on Plainsman P300 and M370 (but was OK on Polar Ice). Fluid melt glazes look best on porcelains so this was obviously a problem. So I continued development in pursuit of a fluid melt having a lower thermal expansion (see subsequent articles, recipes and posts).

Pictures

Copper Blue G8306C using copper carbonate, oxide

Right is G3806C, an adjustment to drop the thermal expansion of B. It does this by trading some of the high-expansion KNaO for a mix of MgO, ZnO and SrO. These is an improvement but it still could craze over time on high-kaolin or low silica porcelains.

One more change: The one on the right uses 2% Copper Oxide instead of 2% Copper Carbonate (left). Both also add 2.5% tin oxide. Strangely the color is only slight darker (the oxide is a more concentrated form of copper than the carbonate).

Plainsman P300, M370 with copper blue glaze cone 6

This is the G3906C base plus 2.5% tin oxide and 2% copper oxide. The green glaze does craze over time on these bodies, but the inside glaze is a liner than will not.

3806C vs. other cone 6 clear glazes on a dark stoneware

Each pair of mugs shows a numbered glaze vs. G3806C on the right. The body is a red burning cone 6 stoneware, Plainsman M390.

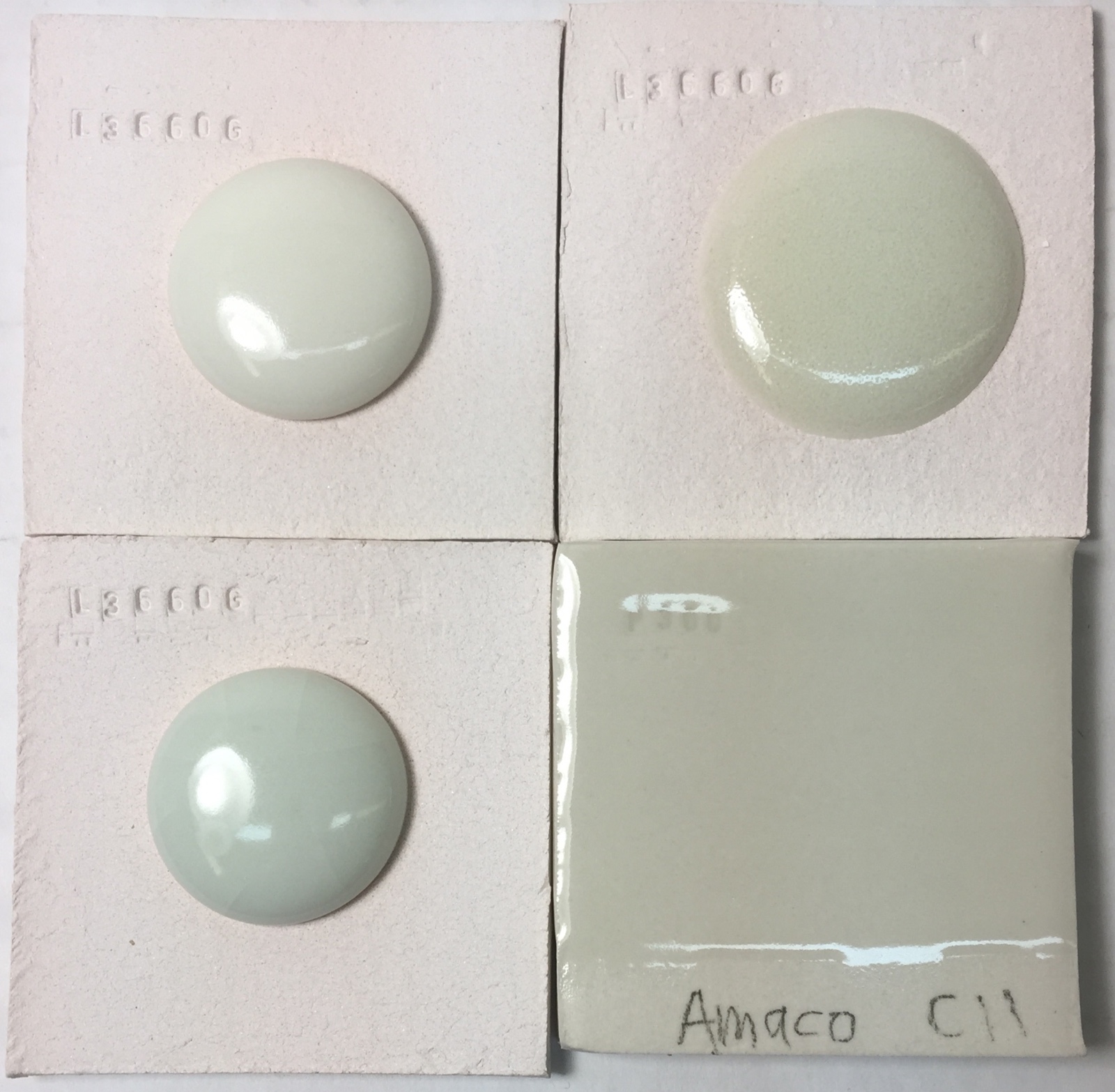

G2926B, 3806C vs. Amaco C11 Clear at cone 6

Bottom right is P300 with three coats of C11.

Bottom left: 10 gram ball of C11.

2926 B is top left, 3806C is top right.

G3806C Copper Blue on Polar Ice

Polar Ice is the easiest of Plainsman middle fire porcelains to fit a glaze to, although this glaze crazes on most other porcelains, it should stay craze free on this.

G3806C on a dark burning cone 6 stoneware

Plainsman M390. There is still some clouding, but it is better than other transparents we have used.

G3806D melt flow test

Left is G3806C with copper oxide 2%. Right is G3806D with copper carbonate 2%. The melt fluidity is identical. The blue color thus seems to depend on the carbonate (or a lower percentage of the oxide is needed).

Variations

1 - Midnight

Fire fast to 2100F (300-400F/hr), then 100F/hr to 2200F, then drop fast to 2000F and soak half hour, then cool at 100F/hr to 1400F.

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Panama Cone 6 Adjustment 2015" keywords="High fluid melt glaze for reactive effects and super gloss colors" id="75786" key="XxJ94hGH" date="2024-07-24" codenum="G3806C" email="untdkm@sasktel.net"> <recipelines> <recipeline material="Silica" amount="26.300" tolerance=""/> <recipeline material="Kaolin" amount="19.700" tolerance=""/> <recipeline material="Dolomite" amount="8.700" tolerance=""/> <recipeline material="Strontium Carbonate" amount="4.400" tolerance=""/> <recipeline material="Ferro Frit 3110" amount="31.100" tolerance=""/> <recipeline material="Ferro Frit 3134" amount="6.600" tolerance=""/> <recipeline material="Zinc Oxide" amount="3.300" tolerance=""/> <recipeline material="Copper Oxide" amount="2.000" added="true"/> <recipeline material="Tin Oxide" amount="2.500" added="true"/> </recipelines> </recipe> </recipes>

Born: 2015-06-02, Modified: 2024-07-24 17:59:11

Panama c6 - Lower COE #1

|

Code # G3806D |

Batch # -2 |

| P | Materials | Amt | |

|---|---|---|---|

| Silica | 26.300 | 26.27% | |

| Wollastonite | 4.000 | 4.00% | |

| Kaolin | 15.700 | 15.68% | |

| Dolomite | 5.700 | 5.69% | |

| Strontium Carbonate | 4.400 | 4.40% | |

| Ferro Frit 3110 | 29.100 | 29.07% | |

| Ferro Frit 3249 | 5.600 | 5.59% | |

| Zinc Oxide | 3.300 | 3.30% | |

| Spodumene | 6.000 | 5.99% |

| P | Additions | ||

|---|---|---|---|

| * | Copper Carbonate | 2.000 | 2.00% |

| * | Tin Oxide | 2.500 | 2.50% |

Total:104.60

Auto Unity Formula

|

Si:Al: 10.8:1 6.9 (Molar:6.6) 6.0 |

Notes

The first adjustment to G3806C, the recipe I have used by some years. I have reduced KNaO and raised Li2O to compensate (Li2O is a powerful flux and has very low expansion). The method to accomplish this is novel.

-Some of the KNaO and almost all of the B2O3 were coming from frit 3134. I removed that and introduced frit 3249. It has no KNaO, plenty of B2O3. But it also has MgO (another low expansion flux). The portion of the MgO that I can supply in-the-frit will melt much better than it does when supplied from dolomite.

-I am sourcing the Li2O from spodumene. Not much is needed because I only need 0.05 molar.

The chemistries of the copper and tin are turned off so they are not participating.

The results have been stunning so far. The fired appearance is almost identical. However it is still crazing on Plainsman P300.

Mixed 2700 water to 3000 dry to get 1.45 SG. Does not respond well to Epsom salts, even at 2g/1000. Slurry is pretty runny but does work fine on quick dips with 1850F bisque. Needs some bentonite to increase particle surface area.

Pictures

G2806D (with copper carbonate) on M340 at cone 6

G3806D melt flow test

Left is G3806C with copper oxide 2%. Right is G3806D with copper carbonate 2%. The melt fluidity is identical. The blue color thus seems to depend on the carbonate (or a lower percentage of the oxide is needed).

G3806D with 2% Copper Carb (left), 2% Copper Ox (right)

G3806C and D - both using Copper Oxide at 2%

G3806D on M340, Polar Ice at cone 6

G3806D on M340, M390 at cone 6

This is the copper oxide version.

Clockwise: G3806C,D,E,F on M370

F is more fluid, thus highlights contours better.

C has 2% copper, the others 3%.

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Panama c6 - Lower COE #1" id="157007" key="7mXCHSs3" date="2024-01-18" codenum="G3806D" email="untdkm@sasktel.net"> <recipelines> <recipeline material="Silica" amount="26.300" tolerance=""/> <recipeline material="Wollastonite" amount="4.000" tolerance=""/> <recipeline material="Kaolin" amount="15.700" tolerance=""/> <recipeline material="Dolomite" amount="5.700" tolerance=""/> <recipeline material="Strontium Carbonate" amount="4.400" tolerance=""/> <recipeline material="Ferro Frit 3110" amount="29.100" tolerance=""/> <recipeline material="Ferro Frit 3249" amount="5.600" tolerance=""/> <recipeline material="Zinc Oxide" amount="3.300" tolerance=""/> <recipeline material="Spodumene" amount="6.000" tolerance=""/> <recipeline material="Copper Carbonate" amount="2.000" added="true"/> <recipeline material="Tin Oxide" amount="2.500" added="true"/> </recipelines> </recipe> </recipes>

Born: 2015-06-02, Modified: 2024-01-18 19:45:42

Plainsman Iron Red Orange

|

Code # G3948A |

Batch # -2 |

| Materials | Amt | |

|---|---|---|

| Ferro Frit 3110 | 20.500 | 20.48% |

| Silica 325 mesh (Silica) | 10.200 | 10.19% |

| EPK | 15.800 | 15.78% |

| Silverline 303 Talc | 13.800 | 13.79% |

| Tricalcium Phosphate | 11.300 | 11.29% |

| Ferro Frit 3134 | 7.000 | 6.99% |

| Spodumene | 21.500 | 21.48% |

| Additions | ||

|---|---|---|

| Black Iron Oxide | 11.200 | 11.19% |

Total:111.30

Auto Unity Formula

|

Si:Al: 7.6:1 6.5 (Molar:6.4) 3.9 Cost 0.68 per kg |

Notes

This fires like Amaco PC-56 Ancient Copper. It is an "iron red". Recipes in use are very problematic (erratic firing, excessive running, gelling in the bucket).

We mix 80:100 water:powder to get a thixotropic slurry (it might be different for you depending on the electrolytes in your water). It does not gel like what happens when using red iron oxide. And application properties are very good.

Initial fired results on all bodies tried were very good using the C6IRED schedule. Later we found the C6DHSC worked well also.

Good control of the slurry rheology is important so that each time you use the glaze is applies as the same thickness for a given immersion time. This is because the thickness of application is the key to the visual effect this produces. Its melt fluidity is high (it is runny) yet a thick application is needed to achieve the visual effect. That means a catch glaze on the outsides of ware is required (this glaze itself can be the catcher if applied thinly). Allowing pooling on the insides of pieces is not advisable, it can produce glaze compression which will cause cracking at a later time.

Some of the pictures do not convey the red color as well as others. This gives much better iron red coloration on dark-burning bodies like M390 or Coffee Clay.

Durability: This could be an issue because of the relatively low Al2O3 and SiO2 (their low levels are the mechanism of the fluid melt - this could fail a vinegar leaching test). We tried using the G3806E base recipe, its thermal expansion is lower, but the iron crystals do not develop (it later became evident the problem was with the chemistry of that base).

Crazing: The thermal expansion calculates fairly low despite low SiO2 and Al2O3, but crazing is still possible. Using 325 mesh silica is important.

A lithium carbonate version of this is also possible (would require chemistry).

Pictures

G3948A on Coffee Clay

Fired using the C6DHSC schedule and the catch glaze technique for application.

G3948A Red Orange Iron Red mugs

Done using our standard C6DHSC slow cool schedule. This in M370.

G3948A Red Orange Iron Red on dark body

The mug on the righty is M390, left is M340.

G3948A Iron Red on Coffee Clay and Polar Ice

C6DHSC schedule

G3948A Iron Red glaze on Polar Ice and M370

Fired at cone 6 using the C6IRED schedule.

Glaze was applied double thickness on the top half of the samples. Clearly this has a high melt fluidity.

G3948A - special iron red firing schedule vs normal slow cool

C6IRED vs. C6DHSC firing schedules.

The latter is working much better.

G3948A vs Amaco PC-56 at cone 6

Using the PLC6DS firing schedule.

G3948A, G3948A and Amaco PC-56

Fired cone 6 using the C6DHSC slow cool firing schedule.

Top left: G3948, the original recipe found at Glazy

Top right: G3948A, our adjustments

Bottom: Amaco PC-56 Ancient Copper

The PC-56 is firing more matte and more heavily crystallized. If you want that then add more iron to the G3948A recipe.

G3948A on M390, M340

C6DHSC firing schedule.

This glaze seems to produce great results on almost any clay!

Of course, if applied thickly on ware a catch glaze will be needed at the bottom to stop overflow.

G3948A vs Amaco PC-56 melt flow

Fired at cone 6 drop and hold.

PC-56 has a slightly greater melt fluidity (suggesting a little more lithium or boron). It is crystalizing, indicating more iron oxide (in my opinion a little too much).

G3948A closeup

G3948A Iron Red to cone 6, 5, 4 on Coffee Clay

They were fired at cone 6, 5 and 4 using the C6DHSC schedule (adjusted for top temperature).

Iron Red gone wrong?

Mar 2023: We mixed the recipe multiple times and kept getting this. The problem turned out to be filling our TCP jar with the wrong material, likely Pyrophylite.

XML (to paste into Insight)

<?xml version="1.0"?> <recipes version="1.0" encoding="UTF-8"> <recipe name="Plainsman Iron Red Orange" id="218094" key="phCKvgzX" date="2024-03-13" codenum="G3948A" email="jrspiteri@comcast.net"> <recipelines> <recipeline material="Ferro Frit 3110" amount="20.500" tolerance=""/> <recipeline material="Silica 325 mesh" lookup="Silica" amount="10.200" tolerance=""/> <recipeline material="EPK" amount="15.800" tolerance=""/> <recipeline material="Silverline 303 Talc" amount="13.800" tolerance=""/> <recipeline material="Tricalcium Phosphate" amount="11.300" tolerance=""/> <recipeline material="Ferro Frit 3134" amount="7.000" tolerance=""/> <recipeline material="Spodumene" amount="21.500" tolerance=""/> <recipeline material="Black Iron Oxide" amount="11.200" added="true"/> </recipelines> </recipe> </recipes>

Born: 2022-06-21, Modified: 2024-03-13 20:09:46